Cement belt conveyor

What is Cement belt conveyor?

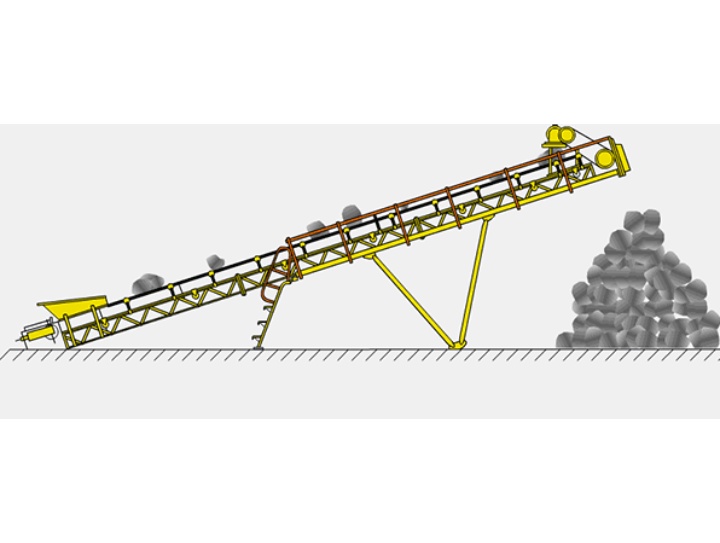

Cement belt conveyors are a basic and common type of equipment, whose core function is to provide continuous transport of bulk materials. Based on their structure and purpose, these types of equipment are primarily categorized as rubber belt conveyors, high-angle conveyors, and corrugated sidewall conveyors. In practice, their material handling capacity ranges from tens to thousands of tons per hour, adapting to production needs of varying scales. In terms of conveying distances, these devices can effectively connect different work locations over distances ranging from hundreds of meters to several kilometers, forming a continuous material flow network.

What are the types of cement belt conveyors?

Cement belt conveyors are primarily used to transport bulk materials such as cement, clinker, and limestone, with the conveyor belt being their core component. Conveyor belt materials vary depending on the operating conditions, material properties, and environmental requirements. The following are some common types of cement belt conveyor belt materials:

Rubber conveyor belts

This is a common and widely used type of conveyor belt in the cement industry. Rubber belts typically consist of multiple layers of fabric (such as cotton, nylon, or polyester) as the backbone, coated with a wear- and corrosion-resistant rubber outer layer. Advantages: Excellent wear resistance and high tensile strength, suitable for large-volume, long-distance conveying. The rubber material effectively resists impact and abrasion from hard materials such as cement and clinker.

Disadvantages: Specially formulated rubber may be required in certain environments, such as those exposed to oil or chemical corrosion.

Nylon Conveyor Belts

Nylon conveyor belts are primarily constructed from nylon fabric, offering a lightweight and high-strength structure.

Advantages: Lightweight, high strength, fatigue resistance, impact resistance, and good troughing properties, making them suitable for conveying on steep slopes.

Disadvantages: Relatively poor heat resistance, making them unsuitable for conveying high-temperature materials (such as clinker fresh from the kiln). They may deform due to moisture absorption in humid environments.

Corrugated Sidewall Conveyor Belts

These conveyor belts are typically made of rubber or polyester, but are distinguished by their corrugated sidewalls and incorporation of crossbars.

Advantages: They can convey at large angles or even vertically, effectively saving space and reducing construction investment. The sidewalls and crossbars effectively prevent material spillage. Disadvantages: Relatively complex structure and high cost.

What are the advantages of cement belt conveyors?

With its powerful conveying capacity, smooth operation, and low operating costs, cement belt conveyors have become an indispensable core equipment for material transportation in the cement industry. Cement belt conveyors are widely used in cement production and the building materials industry. Their advantages are primarily reflected in the following aspects:

High conveying capacity and high efficiency: Belt conveyors enable continuous, high-volume material transportation, typically reaching hundreds or even thousands of tons per hour. This continuous conveying method significantly improves production efficiency and reduces waiting time between material stages compared to intermittent truck or bucket transport.

Long conveying distances and a wide range of applications: Belt conveyors can easily transport materials over long distances, from a few meters to several kilometers or even longer. With appropriate design, they can traverse complex geographical environments such as hillsides, rivers, and roads, transporting materials directly from mines to cement plants. Furthermore, they can accommodate a variety of conveying angles, including steep inclines and even vertical conveying, making them highly flexible in various terrains and plant layouts.

Stable Operation: Belt conveyors operate smoothly, with minimal noise and vibration. Driven by a motor, they consume relatively little energy, making the unit material transportation cost significantly lower than using trucks or other transportation methods, especially for long-distance transport. Their simple structure also allows for easy maintenance, resulting in relatively low daily operating costs.

Simple Operation and High Level of Automation: Cement belt conveyors can be remotely controlled and operated automatically. The control system precisely adjusts conveying speed and material flow, enabling integration with other production equipment, reducing manual intervention and improving the automation and reliability of the production line.

Cement Belt Conveyor Parameters

|

width (mm) |

Conveying length(m) power(kw) |

transfer speed (m/s) |

Delivery volume (t/h) |

||

| 400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 | 30-60 |

| 500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 | 40-80 |

| 650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 | 80-120 |

| 800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 | 120-200 |

| 1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 | 200-320 |

| 1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 | 290-480 |

| 1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 | 400-680 |

| 1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 | 600-1080 |

| 1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 | 800-1500 |

| 2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 | 1000-2000 |

| 2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 | 1500-3000 |

How does a cement belt conveyor work?

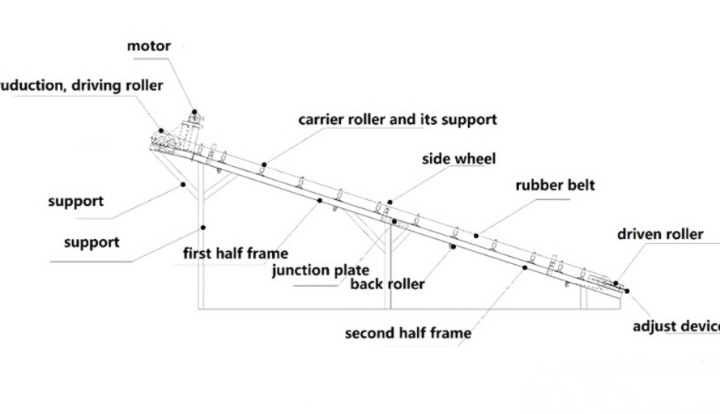

A cement belt conveyor uses friction to continuously and smoothly transport materials from one location to another. Its core component is a closed conveyor belt. This belt loops around two front and rear rollers (a drive roller and a bend roller). When the drive unit (typically a motor and a reducer) is activated, it rotates the drive roller. Friction between the belt and the drive roller causes the conveyor belt to move forward. The material to be conveyed, such as cement, clinker, or limestone, is fed through a chute and smoothly discharged onto the upper conveyor belt. The upper conveyor belt, carrying the material, is supported by supporting rollers below, which keep it in a defined groove and prevent spillage. Driven by the continuous action of the drive roller, the conveyor belt carries the material forward. When the material reaches the end of the conveyor (usually where the drive roller is located), the conveyor belt passes around the roller and changes direction, allowing gravity to release the material from the conveyor belt and discharge it to a designated location, such as a silo or equipment for the next process. The unloaded conveyor belt, now unloaded, passes around the return roller at the end and, supported by return rollers, returns to the drive roller, completing the cycle. Throughout this operation, the tensioning device continuously adjusts the belt tension to prevent slippage or slack, ensuring stable conveyor operation. In short, the operating principle of a cement belt conveyor is like an endlessly rotating track, with the driving force driving the conveyor belt to achieve continuous and smooth material transportation.

What are the structural features of a cement belt conveyor?

A cement belt conveyor is a mechanical device used for continuously conveying bulk materials such as cement, clinker, and limestone. While there are various types, their basic structure consists of a conveyor belt, drive unit, drive rollers, and bend pulleys.

Conveyor belts: This is the core load-bearing component of the conveyor, directly carrying and moving the material. Conveyor belts typically consist of multiple layers of a skeleton material (such as nylon, polyester, or steel cord) and an outer rubber cover. The cover material and formulation vary depending on the material properties and operating conditions, such as heat-resistant rubber for conveying high-temperature clinker or wear-resistant rubber for general materials.

Drive unit: The drive unit is the conveyor's power source and typically consists of components such as an electric motor, a speed reducer, a coupling, and a brake. It provides the necessary tension to the conveyor belt through the drive rollers, enabling continuous motion. On long-distance or high-capacity conveyors, dual or multi-drive systems may be used to ensure sufficient driving force and reduce tension on the conveyor belt.

Drive rollers, also called head rollers, are the key components connecting the conveyor belt to the drive unit. It drives the conveyor belt forward through friction and also serves as the discharge end. The roller surface is typically coated with rubber to increase friction and prevent the belt from slipping.

Bend pulley: Also called the tail pulley, it is located at the end of the conveyor and is used to change the direction of the conveyor belt. It does not provide power, but works in conjunction with a tensioning device to adjust the belt tension.

Tensioning device: The tensioning device maintains proper belt tension to ensure sufficient friction between the belt and the drive pulley, preventing slippage and reducing belt slack and vibration during operation. Common tensioning methods include screw, weight, and hydraulic tensioning.

What are the applications of cement belt conveyors?>

Cement belt conveyors are widely used in the cement industry, construction, and other related fields, primarily for conveying various bulk materials, forming a complete material flow system.

Cement belt conveyors are ubiquitous throughout the entire cement production process, playing a critical role in material handling. Mining and Pre-homogenization: At the mining sites of raw materials such as limestone, sandstone, and clay, belt conveyors transport crushed materials from the mining site to the stockpile for pre-homogenization, providing a stable and uniform raw material for subsequent production.

Raw Material Transportation: Pre-homogenized raw materials (such as limestone, clay, and iron powder) are transported from the stockpile to the raw mill, or from various raw material silos to the batching system.

Clinker Transportation in the Kiln: At the exit of the rotary cement kiln, conveyors transport clinker, which can reach temperatures of hundreds of degrees Celsius, to the clinker cooler or clinker silo. High-temperature-resistant conveyor belts are typically used.

Finished Product Transportation: Finished cement is transported to the cement silo, or from the silo floor to the packaging machine or bulk distribution point.

In-Plant Material Transfer: Within the cement plant, belt conveyors connect various production processes, such as from the crushing station to the raw material silo, from the raw material silo to the raw mill, and from the clinker silo to the cement mill. In general, cement belt conveyors are used in a wide range of processes, from raw material collection and processing to finished product distribution. They are one of the most commonly used and reliable equipment for continuous bulk material conveying.

Cement belt conveyors play an indispensable role in current industrial production. The continuous conveying capabilities they provide solve the problem of transferring large amounts of bulk materials between different production stages. Whether transporting raw materials from mines to factories or connecting various processes within a factory, a stable and continuous material flow is essential for maintaining normal production line operation. Their structure, consisting of core components such as the drive unit, conveyor belt, rollers, and idlers, features a mature design and relatively straightforward maintenance.