Fertilizer belt conveyor

What is Fertilizer belt conveyor?

Fertilizer belt conveyors, as a common material handling equipment, play a vital role in the fertilizer industry. Depending on the specific operating environment and material characteristics, common belt conveyor structures include sidewall belt conveyors capable of conveying at large angles, telescopic belt conveyors with adjustable lengths, and Z-type belt conveyors capable of both horizontal and vertical conveying. Their operational scope ranges from small batches of a few tons per hour to large-scale conveying of hundreds of tons per hour, with conveying distances ranging from a few meters to tens of meters per unit.

What are the types of fertilizer belt conveyors?

Belt conveyors are essential equipment in the fertilizer production and packaging process. Depending on the application scenario and functional requirements, there are several common types of fertilizer belt conveyors, with sidewall belt conveyors, telescopic belt conveyors, and Z-type belt conveyors being the most common. The following provides a detailed introduction to these three types of conveyors based on their structural characteristics, conveying capacity, and conveying distance.

Sidewall Belt Conveyor

Structural Features: Sidewall belt conveyors are characterized by corrugated sidewalls on both sides of the conveyor belt and partitions running transversely along the conveyor belt. This structure effectively prevents material spillage due to tilting or centrifugal force during conveying, making it particularly suitable for conveying materials at large angles and high inclinations.

Capacity: The conveyor belt has a relatively high capacity because it utilizes the entire cross-section of the conveyor belt and can convey vertically or at large angles, thus saving space.

Conveying Distance: Conveying distances are typically short and are primarily used for vertical lifting or conveying materials at large inclinations, such as conveying fertilizer from the ground to a high-rise silo, packaging machine, or mixing equipment.

Telescopic Belt Conveyor

Structural Features: Telescopic belt conveyors have a telescopic function, allowing them to extend and retract freely like a telescope. This design allows the conveyor length to be adjusted as needed to accommodate various loading, unloading, or stacking operations.

Capacity: The conveying capacity is moderate, depending primarily on the belt width and operating speed. Its main advantage is its flexibility, allowing the conveying capacity to be adjusted according to actual operational needs. Conveying Distance: The conveying distance is flexible and can range from a few meters to over ten meters. It is primarily used for loading and unloading cargo, such as transferring fertilizer bags directly from a warehouse or workshop into a truck or container, significantly improving loading and unloading efficiency.

Z-Type Belt Conveyor

Structural Features: This conveyor consists of a series of connected hoppers attached to a chain or belt. It typically takes a "Z" shape and can transport materials horizontally, vertically, and again horizontally. Because materials are conveyed within the enclosed hoppers, dust escape and material contamination are effectively prevented.

Conveying Capacity: It generally achieves high conveying capacity and is particularly suitable for the continuous lifting and conveying of bulk, granular, or lumpy materials.

Conveying Distance: Primarily used for vertical conveying, it has a shorter horizontal conveying distance but can easily achieve vertical lifts of tens of meters or even higher. It is ideal for transporting fertilizer from lower production lines to higher packaging lines or storage tanks.

What are the advantages of a fertilizer belt conveyor?

It's no coincidence that belt conveyors are indispensable equipment in fertilizer production and packaging lines. Compared to other types of conveying equipment, belt conveyors offer several significant advantages:

Simple structure and reliable operation: The main components of a belt conveyor include a conveyor belt, rollers, idlers, and a drive unit. This simple structure reduces failure rates and facilitates maintenance. If problems do occur, they are generally easy to diagnose and repair, ensuring continuous and stable operation of the production line and reducing downtime.

High conveying efficiency and wide application range: Belt conveyors enable continuous, high-speed material transport with large throughputs. Whether it's granular compound fertilizer, urea, or powdered diammonium phosphate, belt conveyors can handle them. Furthermore, they can adjust the conveying angle and speed as needed to accommodate different production processes and layouts.

Smooth conveying without material damage: Fertilizer moves smoothly on the conveyor belt, without violent jolting or impact. This is particularly important for fragile and easily agglomerated fertilizer products, effectively reducing material damage during conveying and maintaining product integrity, thereby improving product quality.

Flexible conveying distance and direction: By designing and combining different belt conveyors, conveying over long distances, on steep slopes, or in complex spaces can be achieved. For example, telescopic conveyors can be used for loading and unloading, or sidewall belt conveyors can be used for vertical lifting. This flexibility allows belt conveyors to adapt to various factory layouts and production processes.

Parameters of Fertilizer Belt Conveyors

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

How does a Fertilizer Belt Conveyor work?

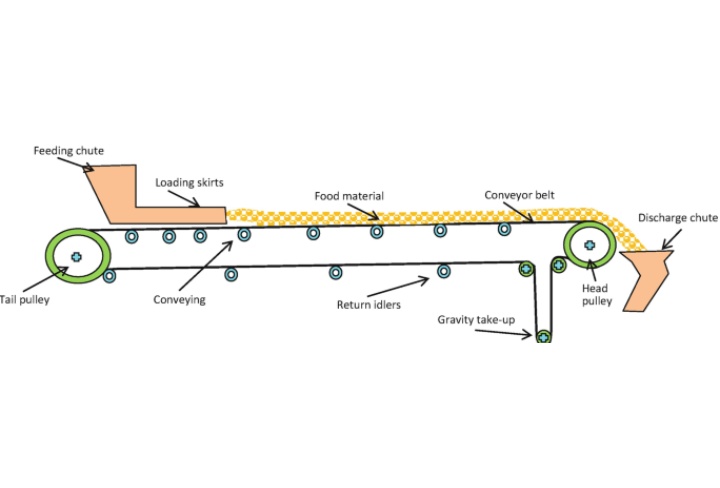

The core of the Fertilizer Belt Conveyor's operating principle lies in its continuous, circular motion. This system consists of several key components that work together to ensure smooth material transport from one point to another. First, power comes from an electric motor, which uses a speed reducer to convert high-speed rotation into slow, high-torque motion. This power is then transmitted to the drive roller, becoming the core force driving the entire conveyor belt. The conveyor belt itself is a seamless, endless belt that tightly wraps around the drive roller and the return roller at the other end, forming a closed loop. Beneath the conveyor belt, rows of rollers are evenly spaced. These act like railroad sleepers on a track, providing stable and strong support for the conveyor belt and preventing it from sagging and deforming due to the material it carries. When fertilizer falls from the feed inlet onto the conveyor belt, the drive rollers propel it forward smoothly, carrying the material. Upon reaching the designated location, the material is automatically unloaded due to the belt's curvature and gravity. The unloaded conveyor belt then continues its cycle, returning to its starting point to prepare for the next batch of material, thus achieving uninterrupted, continuous conveying. Simply put, the principle of a belt conveyor is to use a motor-reducer-drive roller system to continuously drive the conveyor belt in a reciprocating motion, thereby achieving continuous transportation of material from one location to another.

What are the applications of fertilizer belt conveyors?

Due to their continuous, stable, and flexible nature, fertilizer belt conveyors are widely used in all stages of fertilizer production, from raw material processing to finished product packaging.

Raw material conveying: At the initial stage of fertilizer production, belt conveyors are used to transport various raw materials (such as phosphate rock, urea, and potash fertilizer) from warehouses, storage yards, or train cars to silos or the head end of the production line. High-capacity conventional belt conveyors or long-distance belt conveyors are typically used to ensure a continuous and stable supply of raw materials.

Material Transport in the Process: In the fertilizer production process, belt conveyors play a critical role in material transfer between stages such as granulation, drying, and cooling. For example, they can be used to transport wet granules after granulation to a dryer or to transport finished granules after cooling to a screening machine. In this process, sidewall belt conveyors, due to their ability to convey at large angles, are often used to lift materials from lower production equipment to higher equipment.

Finished Product Packaging and Loading: This is a common application for belt conveyors. After metering, finished fertilizer granules or powder are transported by belt conveyor to a packaging machine for bagging. The bagged products are then transported by belt conveyor to a stacker or directly to trucks or train cars for loading. In this process, telescopic belt conveyors can improve loading efficiency because they can flexibly adjust to the length of the car, reducing manual handling and saving time and manpower. Warehousing and Storage: In fertilizer storage, belt conveyors are used to transport finished fertilizer to various warehouses or open storage yards. By strategically planning conveyor routes, materials can be easily moved in and out of storage. Large storage yards often utilize mobile belt conveyors, allowing for flexible movement according to the location of the material being stored.

The application of belt conveyors in fertilizer production demonstrates their applicability in material handling. These devices play different roles in different production processes, handling a variety of material forms. When selecting and using a conveyor, the specific conveying requirements and site conditions require consideration of the device's structural characteristics, load capacity, and operating mode. Whether used for incoming raw materials or loading finished bags onto trucks, each type of conveyor has specific application scenarios and corresponding operating requirements. Proper configuration and use of these devices ensures that materials flow through the production process as planned and routed.