PVC belt conveyor

What is PVC belt conveyor?

PVC belt conveyors are a type of material handling equipment used in light industry and logistics. Depending on the characteristics of the conveyor belt, these types come in various types, including standard, patterned, oil-resistant, anti-static, and food-grade, to suit different working environments and material requirements. Their handling capacity typically ranges from several to dozens of tons per hour, and conveying distances range from a few to dozens of meters. They are primarily used for short-distance material transfer. This type of equipment plays a fundamental role in production lines and sorting processes, ensuring the smooth flow of materials.

What types of PVC belt conveyors are there?

PVC belt conveyors are primarily categorized by the material and surface characteristics of the belt to meet the conveying needs of different industries and materials. Common types include patterned belts, anti-static belts, oil-resistant belts, and food-grade belts.

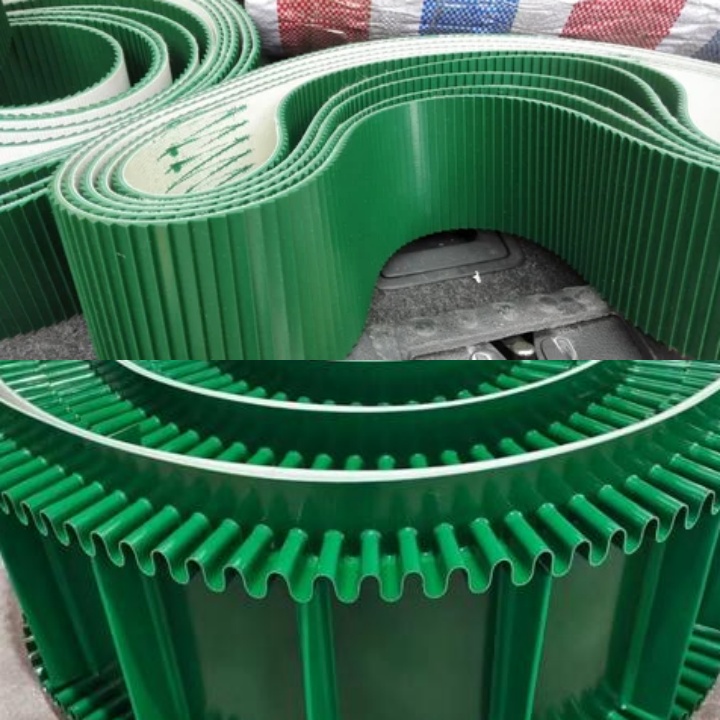

Patterned belts

Patterned belts have various uneven patterns on their surface, such as herringbone, grass-leaf, and herringbone. This design increases friction between the belt and the material.

Features: They offer strong anti-slip properties, making them particularly suitable for conveying materials at steep angles, preventing them from sliding down.

Applications: They are commonly used for conveying granular or bagged materials or in applications requiring uphill climbs, such as coal, grain, and cement.

Anti-static belts

Anti-static belts are PVC conveyor belts made by adding conductive materials during the production process, giving them the ability to dissipate static electricity.

Features: They have low surface resistance and effectively dissipate static charges, preventing fires or explosions caused by static sparks.

Applications: They are primarily used in industries sensitive to static electricity, such as electronics manufacturing, tobacco, textiles, and the transportation of some flammable and explosive chemical raw materials.

Oil-Resistant Belts

The surface rubber of oil-resistant belts uses a special oil-resistant formula, making them highly resistant to grease and oil.

Features: They will not swell, deform, or corrode due to prolonged contact with oily materials, maintaining the stability and service life of the conveyor belt.

Applications: They are widely used in industries exposed to animal and vegetable oils and lubricants, such as food processing (e.g., meat and fried foods), machinery manufacturing, and automotive parts production.

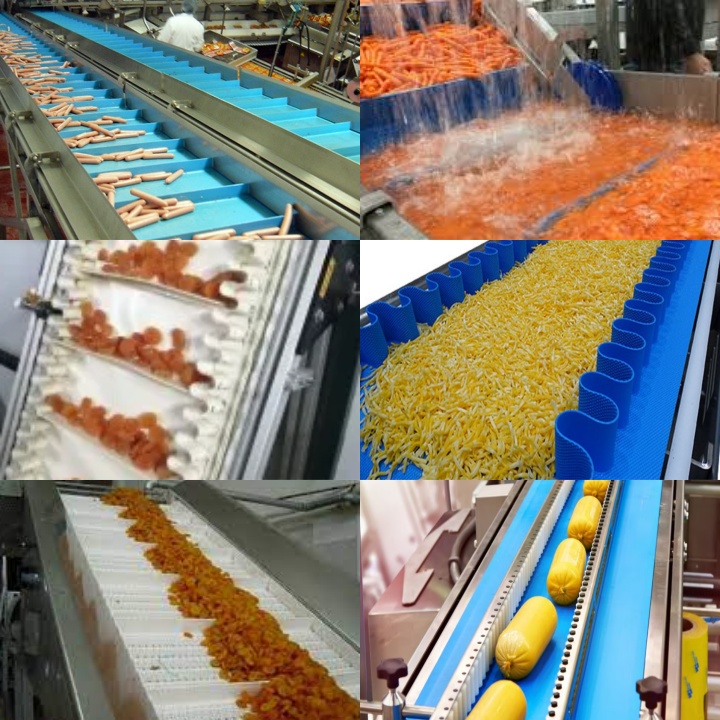

Food-Grade Belts

Food-grade belts are conveyor belts designed for the food industry. Made from non-toxic and odorless materials, they meet food hygiene and safety standards.

Features: They offer a smooth, easy-to-clean surface, are antibacterial and mildew-resistant, and will not contaminate food.

Applications: They are suitable for various food processing applications, such as baking, conveying, sorting, and packaging meat, vegetables, and fruit.

What are the advantages of PVC belt conveyors?

PVC belt conveyors are a practical choice for conveying light and medium-duty materials due to their low cost, hygienic and easy-to-clean characteristics, chemical resistance, and lightweight and flexible design. Its main advantages are as follows:

Cost-Effectiveness: Compared to some heavier conveyor belts (such as rubber belts), PVC belts have a lower initial manufacturing cost. This makes PVC conveyors an economical choice for applications with limited budgets or light to medium loads. Furthermore, their lower weight means they require less energy to operate, further reducing operating costs.

Hygienic and Easy to Clean: PVC's surface is typically smooth and flat, making it less prone to accumulating dirt and bacteria. Its excellent resistance to grease, moisture, and many chemicals makes cleaning and maintenance simple. This makes PVC conveyors particularly suitable for industries with high hygiene standards.

Good Chemical Resistance: PVC belts are resistant to a wide range of chemicals, acids, bases, and solvents, allowing them to operate reliably in environments where chemical contact is unavoidable, preventing premature failure due to corrosion and extending the life of the equipment.

Lightweight and Easy to Install and Maintain: The low weight of the PVC belt itself makes the entire conveyor structure lighter, making it easier to move and install. When belt replacement is necessary, the operation is relatively simple, minimizing downtime and ensuring continuous production.

Adaptability: PVC belt conveyors can be customized to meet diverse application requirements, such as adding patterns, skirts, or partitions to accommodate steep conveying angles or prevent material spillage. Furthermore, they can be specially treated to be anti-static or flame-retardant, enabling them to flexibly meet the unique operating conditions of various industries.

PVC Belt Conveyor Parameters

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

What are the Applications of PVC Belt Conveyors?

PVC belt conveyors are primarily used for the continuous automated handling of light and medium-sized materials. Their primary applications are conveying lightweight, small items in environments requiring hygiene, connecting workpieces in light automated production lines, and in environments requiring anti-static or corrosion resistance. PVC belt conveyors are particularly well-suited for conveying small, lightweight items such as parcels, cartons, parts, and packaging bags. They can move items along the production line at a steady speed, ensuring that items are not damaged during transport. Because PVC belts are smooth, easy to clean, and non-toxic and odorless, they are often used in environments requiring high hygiene. This includes applications handling food, pharmaceuticals, or any other materials requiring stringent cleanliness requirements. As a key piece of equipment in automated production processes, PVC belt conveyors connect different workstations, ensuring smooth material flow. For example, they can connect upstream processing equipment with downstream packaging or assembly areas, forming a complete production chain. Depending on requirements, PVC belts can be enhanced with special ingredients to impart anti-static or chemical resistance. This allows them to operate safely in static-sensitive electronics manufacturing environments or where they come into contact with weak acids and bases.

PVC Belt Conveyor Price

PVC belt conveyor prices are influenced by a variety of factors, and the specific price is determined based on the customer's customized requirements. Generally, PVC belt conveyor prices can range from several thousand yuan to tens of thousands of yuan. Various factors influence PVC belt conveyor prices, including conveyor size. Conveyor length, width, and height are key determinants of price. Longer and wider conveyors require more belt and frame material, naturally increasing manufacturing costs. Special conveyor height requirements (such as steep inclinations) will also increase design and manufacturing costs. PVC conveyor belts come in many different types, and prices vary significantly. For example, ordinary PVC belts are relatively inexpensive, while special-purpose belts, such as patterned belts (for anti-slip properties), food-grade belts (for hygiene compliance), anti-static belts, or oil-resistant belts, can be more expensive due to their more complex materials and production processes. Besides the basic structure, a conveyor can also be equipped with various features based on specific requirements, all of which will affect the final price. Common features include speed adjustment, baffles and skirts, frame material, and automated controls. Overall, the price of a PVC belt conveyor is a comprehensive consideration, requiring customization based on specific operating conditions, conveying material characteristics, and functional requirements. To obtain an accurate quote, provide PVC belt conveyor suppliers with detailed requirements for evaluation.

PVC Belt Conveyor Manufacturers

The core competence of PVC belt conveyor manufacturers lies in their ability to provide highly customized solutions tailored to specific customer needs. Unlike mass-produced standardized products, manufacturers focus on closely integrating every aspect of the conveyor's functions, dimensions, and materials with actual operating conditions. This customization capability is reflected in several aspects. First, in terms of size and structure, manufacturers can precisely design conveyor length, width, height, and inclination angle based on the customer's production line layout and site constraints. Whether navigating narrow aisles or lifting materials across floors, manufacturers can meet these requirements through professional structural design. For example, when the conveyor belt needs to curve, they can provide a curve conveyor; when frequent adjustments to the conveying length are required, they can provide a telescopic conveyor. Secondly, customization is another major advantage in terms of conveyor belt material and function. In addition to standard PVC belts, manufacturers can select specialized conveyor belts based on the characteristics of the conveyed materials and environmental requirements. For example, they provide food-grade, easy-to-clean belts for the food industry; anti-static belts for the electronics industry to protect delicate components; and belts with patterns or partitions to prevent material from slipping when conveying on slopes. Furthermore, they can provide belts with special properties such as oil resistance, wear resistance, or flame retardancy to cope with various complex working conditions. Finally, customization is also reflected in the drive and control systems. Manufacturers can configure motors and reducers of different powers according to the customer's conveying volume and speed requirements, and integrate variable frequency speed regulation systems to achieve precise speed control.

When selecting the appropriate PVC belt conveyor, several practical factors must be considered. First, the nature of the conveyed material, including its weight, size, and special requirements (such as anti-slip, anti-static, or oil-resistant requirements), will directly determine the type of conveyor belt. Second, the specific dimensions and layout of the equipment, including the conveyor's length, width, and installation height, must be compatible with the existing production site and equipment. Furthermore, the need for adjustable conveyor speeds must be considered to determine whether variable frequency speed control is required. These practical parameters are crucial factors in selecting equipment to ensure it meets specific operating requirements.