Sand belt conveyor

What is Sand belt conveyor?

Sand belt conveyors are equipment used to transport bulk materials and are widely used in various industrial production scenarios. Depending on their structure and application requirements, conveyors can be categorized into various types, including fixed, mobile, and high-angle types with corrugated sidewalls. Their handling capacities range widely, from tens to thousands of tons per hour, and conveying distances can range from tens of meters to several kilometers. Conveyor designs and configurations vary depending on the operating environment and material characteristics, and they can accommodate various conveying paths, including horizontal, inclined, and vertical, making them a crucial component of material handling systems.

What are the types of sand belt conveyors?

Based on their structure and application, sand belt conveyors can be categorized into several types. Fixed, mobile, and high-angle types with corrugated sidewalls are three of the most representative. These different types of conveyors, with their unique designs, meet diverse material handling needs, from long-distance continuous conveying to flexible movement and vertical lifting.

Fixed Belt Conveyor

Features: They are sturdy and typically mounted on a fixed foundation, preventing them from moving freely. They consist of a frame, drive unit, rollers, idlers, and a conveyor belt, and are driven by an electric motor to achieve continuous material transport. Applications: Suitable for long-distance, high-volume, continuous material transport. They are often used as backbone conveying equipment in fixed production lines such as quarries, mines, docks, power plants, and cement plants.

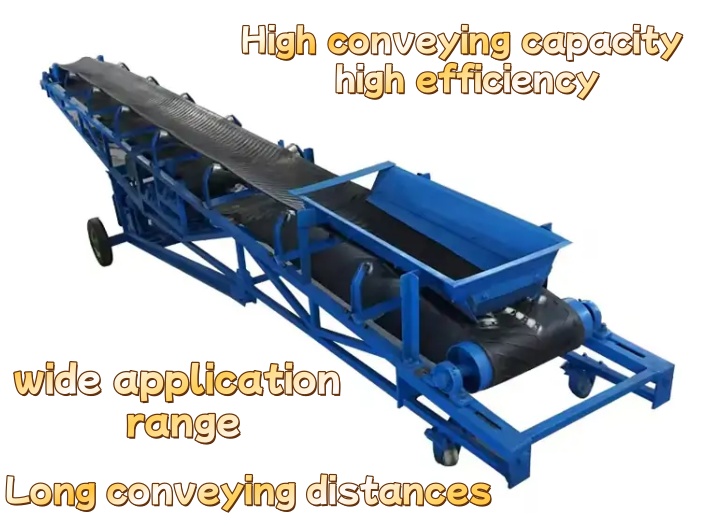

Mobile Belt Conveyor

Features: Typically equipped with wheels, they can be moved to different work locations as needed. They are relatively lightweight and typically utilize a hydraulic lift system, allowing for adjustable conveying height and angle.

Applications: Suitable for applications requiring frequent relocation, such as construction sites, temporary storage yards, and bulk material handling. They facilitate the transfer of materials from one location to another or can be used to stack materials.

High-Angle Belt Conveyor

Features: While traditional belt conveyors typically have an inclination angle of no more than 18°, high-angle conveyors can achieve angles ranging from 30° to 90°. The key is the conveyor belt, which typically features a special structure with corrugated sidewalls and cross-partitions, creating a "box-like" space to prevent material from slipping due to excessive inclination during conveying. Applications: Suitable for applications requiring vertical or high-angle lifting of materials, such as lifting materials from low to high within confined spaces, thus saving floor space. Sand belt conveyors are commonly used in special applications requiring vertical lifting, such as underground mining, blast furnace loading, and waste disposal.

What are the advantages of sand belt conveyors?

With their unique structure and operating method, sand belt conveyors offer continuous, stable, and adaptable conveying capabilities, improving production efficiency and reducing operating costs, making them indispensable in the sand and gravel aggregate industry. Their key advantages are reflected in the following aspects:

High conveying capacity and high efficiency: Belt conveyors operate continuously, delivering large and stable conveying capacities. They can adjust conveying speeds according to production needs, easily handling large conveying capacities ranging from tens to thousands of tons per hour, improving production line efficiency.

Long conveying distances and wide application range: They can transport materials over long distances, even across complex terrain such as valleys and rivers. Belt conveyors offer a variety of designs to adapt to straight, curved, and steeply angled routes, making them versatile and adaptable to a variety of complex production environments.

Smooth Operation and Low Noise: The continuous belt conveyor system ensures smooth operation, free of shock and vibration, resulting in low noise levels. Furthermore, conveyors are typically equipped with dust covers or sprinklers to effectively reduce dust generated during conveying.

Simple Structure and Easy Maintenance: Belt conveyors feature highly standardized components and a relatively simple structure. Routine maintenance tasks such as inspections, belt replacements, and roller adjustments are relatively easy and require no complex technical support, significantly reducing equipment downtime.

Flexible Conveying Distances and Angles: Conveyors can easily handle long-distance conveying tasks, such as transporting materials directly from the extraction point to the processing plant in mines or quarries. Furthermore, using high-angle belt conveyors allows for vertical or high-angle lifting of materials, effectively utilizing space and reducing floor space.

Sand Belt Conveyor Parameters

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

What are the functions of a sand belt conveyor?

The core function of a sand belt conveyor is to provide stable and continuous conveying of bulk materials. It plays a vital role in sand and gravel production lines. Its primary function is to continuously convey sand and gravel materials, with flexible adjustment of conveying distance and direction, enabling automated integration into production lines.

Continuous conveying and material handling: It enables the continuous transport of bulk materials such as sand, gravel, ore, and coal from one workstation to another, such as from a crusher to a screen, or from a production line to a finished product stockpile. This continuity ensures a smooth production process and avoids material accumulation or interruptions.

Adjustable conveying distance and direction: Belt conveyors can be flexibly designed to suit site requirements. They can transport large quantities of material horizontally or at an angle. For applications requiring climbing slopes, high-angle belt conveyors can transport materials to higher locations, effectively utilizing space.

Automation and integration: Belt conveyors can be integrated with crushers, screens, feeders, and other equipment to form a highly automated production line. Through a central control system, unmanned or reduced-management operation is possible, significantly improving production efficiency and safety. Assisted Sorting and Loading and Unloading: Specialized belt conveyors, such as mobile or foldable conveyors, can be used for loading and unloading materials, or for stacking them. At stockpiles, they can stack materials into various shapes for easier management and subsequent use.

What are the Uses of Sand Belt Conveyors?

Sand belt conveyors have a wide range of important industrial applications, primarily in areas requiring large-scale, continuous conveying of bulk materials. For example, in quarries and mines, they transport raw rock and ore from the extraction site to processing equipment such as crushers and screens, and also transport processed sand and gravel to various stockpiles. At docks, ports, freight stations, or large warehouses, they are used to unload and load bulk materials such as sand, coal, and grain from transport vehicles (such as trucks, trains, and ships), and can stack materials as needed. At large construction sites or infrastructure projects, they are used to transport construction materials such as cement, mortar, and gravel, especially over large distances or height differences. Sand belt conveyors can replace traditional manual handling and improve efficiency. In coal-fired power plants, belt conveyors are the primary means of transporting coal, transferring it from unloading docks or storage yards to the boiler's combustion system, ensuring fuel supply for power generation. In chemical and metallurgical plants, belt conveyors are used to transport various powdered and granular raw materials and semi-finished products, such as ore fines, coke, and sintered ore, forming an indispensable part of the production process. In short, sand belt conveyors are used in scenarios requiring large-scale, long-distance, and continuous transport of bulk materials, making them essential equipment in industrial production.

As a basic material handling device, sand belt conveyors play a key role in many industrial sectors. Their stable physical motion ensures smooth production processes. Conveyors are relatively easy to maintain and can adapt to the operating requirements of diverse operating conditions. Their deployment in various production processes provides a reliable means for continuous material handling. Proper selection and use of the appropriate belt conveyor is a prerequisite for ensuring the proper functioning of material handling systems.