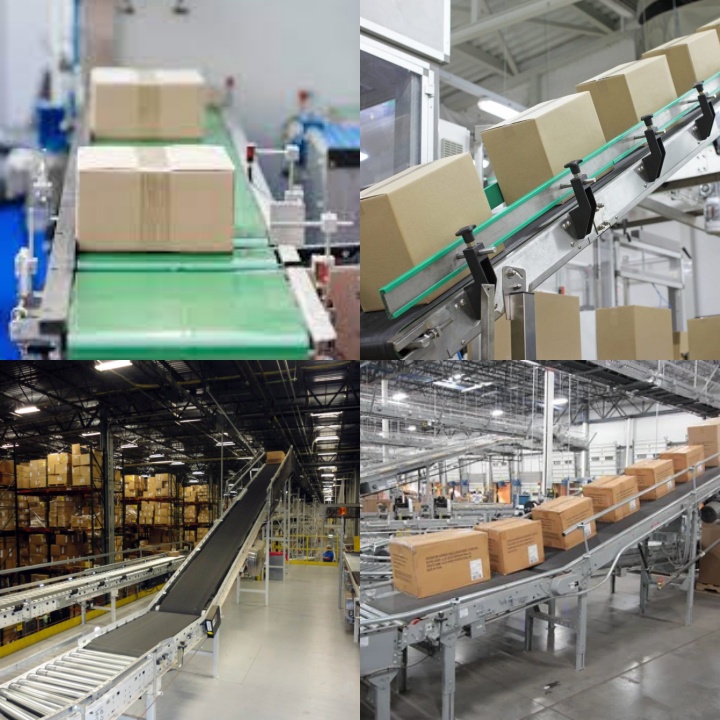

Warehouse belt conveyor

What is Warehouse belt conveyor?

Warehouse belt conveyors are essential and indispensable equipment. Depending on the specific application scenario, belt conveyors can be categorized into various types, including horizontal, inclined, and mobile. Their operating capacity is typically determined by the width and speed of the conveyor belt, allowing them to handle items of varying sizes and weights. For example, a conveyor with a standard width of 600 mm can achieve a linear speed of up to 1.5 meters per second, meeting the needs of handling most common items under specific operating conditions. Conveying distances range from a few meters to tens of meters, covering various material flow paths within the warehouse.

What are the types of warehouse belt conveyors?

Warehouse belt conveyors can be categorized into various types based on their structure and function. However, the most common and fundamental types include horizontal belt conveyors, inclined belt conveyors, and mobile belt conveyors. The following is a detailed introduction to these three types of belt conveyors:

Horizontal Belt Conveyor

Function: Provides horizontal material movement within the warehouse, often used to connect different workstations, such as from the sorting area to the packaging area, or from the packaging area to the shipping area.

Features: Simple structure, easy installation, and smooth operation.

Incline Belt Conveyor

Function: Commonly used for transporting materials between floors, such as moving goods from the ground floor to a second-floor storage area, or from high-rise racks to the ground floor.

Features: To prevent goods from sliding during inclined conveying, this type of conveyor is often equipped with baffles or skirts on the conveyor belt. The inclination angle can generally be adjusted according to actual needs.

Mobile Belt Conveyor

Function: This type of conveyor can be freely moved and extended or shortened as needed. It is primarily used for loading and unloading goods from vehicles. It can be directly inserted into containers or trucks, facilitating loading and unloading, eliminating manual handling.

Features: Equipped with wheels or a base, it can be easily moved to different positions. Some models are telescopic, adapting to the length requirements of different vehicles and spaces.

What are the advantages of warehouse belt conveyors?

As a key piece of equipment in warehousing and logistics systems, warehouse belt conveyors effectively improve operational efficiency and optimize space utilization through automated, continuous conveying, ensuring stable and precise material handling. Its advantages are primarily reflected in the following aspects:

Improved operational efficiency: Belt conveyors enable continuous and smooth material transport, significantly reducing the number of manual handling steps and time. Whether transporting goods from the incoming warehouse to the storage area or from the picking area to the packaging area, they complete the task at a constant speed, thereby improving overall operational efficiency and throughput.

Optimized space utilization: Belt conveyors can be flexibly configured to suit the warehouse's actual layout, including horizontal, inclined, and curved configurations. This allows warehouses to more efficiently utilize both vertical and horizontal space. In multi-story warehouses, inclined conveyors can easily transport materials between floors, optimizing the overall spatial layout.

Improved sorting and processing accuracy: Utilized with automated sorting systems and barcode scanners, belt conveyors enable precise identification and diversion of goods. This not only reduces the potential for manual sorting errors but also ensures that goods are delivered accurately to their designated locations, thereby improving order processing accuracy.

Easy maintenance and expansion: Belt conveyors typically feature a modular design, making installation, commissioning, and maintenance relatively simple. If the warehouse's business volume increases, the conveyor system can be expanded by adding modules to adapt to changing business needs.

Warehouse Belt Conveyor Parameters

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

What are the applications of warehouse belt conveyors?

As a key component of automated logistics systems, warehouse belt conveyors have a wide range of applications, primarily focusing on cargo receiving and sorting, as well as internal material handling and storage. The following are their main application scenarios:

Unloading and Warehousing: When unloading trucks or containers, mobile belt conveyors can directly extend into the vehicle compartment and smoothly transport goods from the vehicle into the warehouse, connecting to the internal conveyor system and eliminating manual handling.

Sorting and Merging: In the sorting center, belt conveyors are core equipment. They transport large quantities of packages or goods from different workstations to the sorting area. Combined with scanning equipment, they divert goods to the corresponding routes or collection points, enabling automated sorting.

Packaging and Shipping: After sorting and packaging, belt conveyors transport the packaged goods to the shipping area for loading. Process Connection: Within a warehouse, belt conveyors act as "conveyor belts," connecting different operational areas. For example, they transport goods from storage to picking, and then from picking to packaging, ensuring the continuity of the entire process.

Floor Conveyance: Inclined belt conveyors can be used in multi-story warehouses to transport goods vertically between floors, moving materials from upper floors to lower floors or vice versa, optimizing warehouse space utilization.

Long-Distance Transport: Within large warehouses or logistics parks, belt conveyors can be used for long-distance horizontal transport, moving materials from one building to another, reducing the need for internal vehicles.

Warehouse Belt Conveyor Case Studies

Warehouse belt conveyors, as a key component of automated logistics systems, play a critical role in material handling and sorting within warehouses. They have a wide range of applications, primarily focusing on scenarios requiring continuous, high-volume transport. When goods arrive at the warehouse, belt conveyors can quickly and smoothly transport them from the unloading area to the staging area or sorting area. Especially for bulk or unpackaged items (such as grain and raw materials), belt conveyors can effectively reduce manual handling, improve warehousing efficiency, and prevent damage during transportation. Within a sorting center or warehouse, they can transport sorted goods to the appropriate packaging station or transport packaged packages to the shipping area. In conjunction with other automated equipment (such as sorters and barcode scanners), they can automatically sort, merge, and divert packages, significantly improving sorting speed and accuracy. In multi-story warehouses, belt conveyors can quickly transfer goods between floors using climbing conveyors or vertical elevators, effectively solving the problem of multi-story space utilization and ensuring smoother material flow. In some manufacturing companies, belt conveyors serve as a bridge between the end of the production line and the finished goods warehouse, automatically transporting finished products to the warehouse for storage, achieving a seamless connection between production and warehousing. In general, warehouse belt conveyors are primarily used in all processes that require continuous, rapid, and stable transportation of goods from one point to another. They are essential equipment for warehouse automation and improving logistics efficiency.

Warehouse belt conveyors can handle multiple material handling tasks, from receiving and sorting to shipping, providing diverse possibilities for material movement within warehouses. Their relatively simple structure makes them easy to maintain and maintain stable operation in diverse environments. Furthermore, they generate minimal noise during operation, limiting their impact on the work environment. By adjusting the type and speed of their conveyor belts, warehouse belt conveyors can accommodate a wide range of material handling requirements, from single packages to large batches of items.