The price of rubber conveyor belt varies greatly, which mainly depends on its model parameters and a series of key influencing factors. Small, light, short-distance conveyors (for example, for small workshops or light-loaded materials, a few meters to more than ten meters long) have a simple structure, so their prices are relatively low; medium-sized, general-purpose conveyors (for example, conventional building materials, coal transportation, dozens of meters long, medium conveying capacity), the price range is around $1,000~$2,000, while large, heavy, long-distance conveyors (for example, large-scale mines and ports, hundreds of meters or even kilometers long, large conveying capacity, steel cord belts) and customized rubber belt conveyors are priced according to the scale and complexity of the project.

|

Configuration category |

Model reference |

Price range (USD) |

|

Small conveyor (≤6 meters) |

B500/B650 |

$800~$1,000 |

|

Medium conveyor (6~12 meters) |

B650/B800 |

$1,000~$2,000 |

|

Large conveyor (≥15 meters) |

B800/B1000 and above |

$2,000~$3,200+ |

|

Special customized type (liftable/movable/with sidewall) |

Any width |

$2,000~$4,000+ |

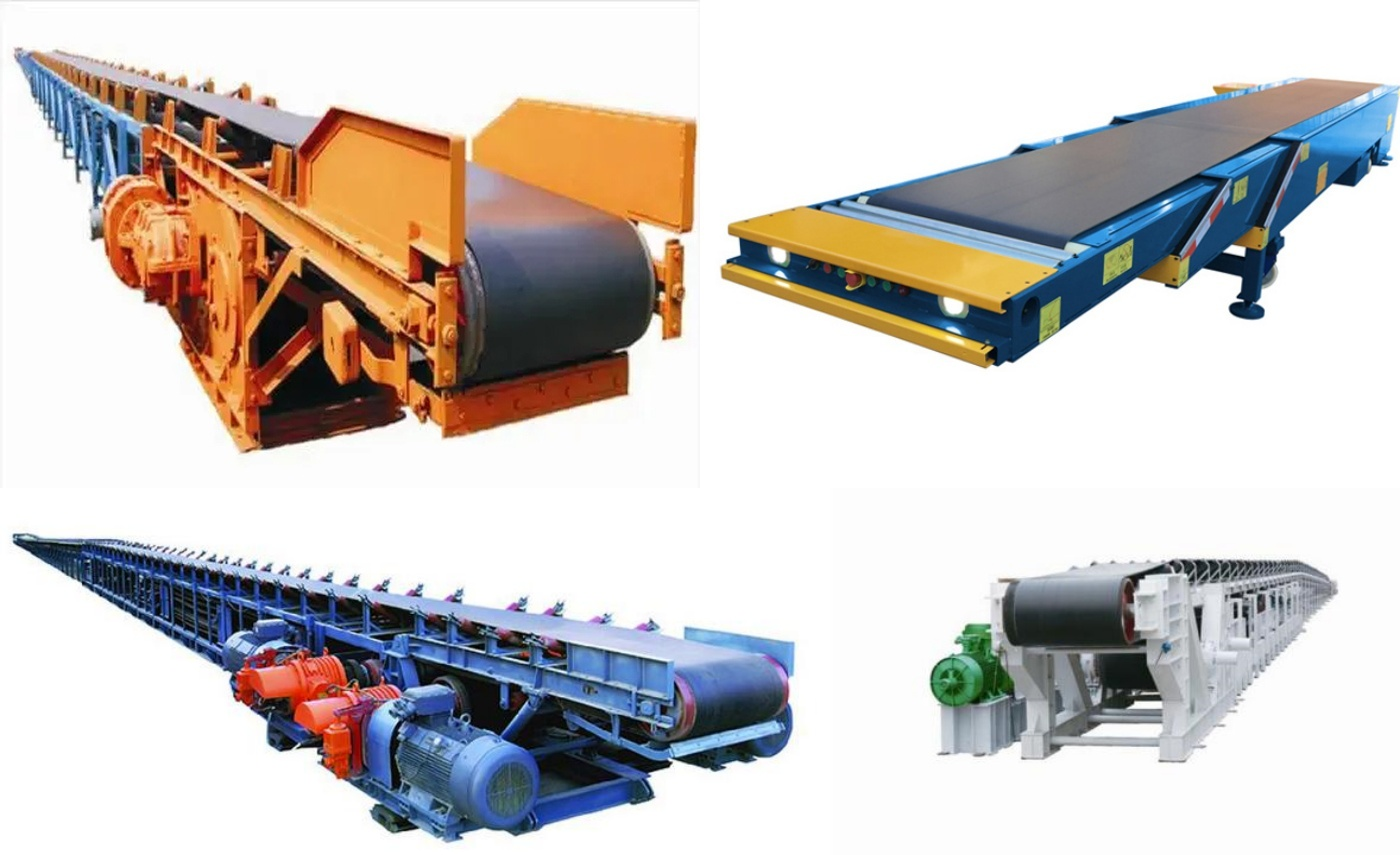

Type and structure:

The general or standard type has a relatively simple structure and a low price. Special types such as large-angle corrugated sidewall conveyors (for vertical or large-angle conveying), tubular conveyors (enclosed conveying, dust and pollution prevention), mobile conveyors, etc., will increase significantly in price due to complex design and high manufacturing difficulty. The larger the conveying capacity, the longer the conveying distance, and the heavier the material of the light, medium, and heavy rubber belt conveyors, the stronger the frame, the wider and thicker the belt, the more powerful the motor and reducer are usually required, and the price will increase accordingly.

Conveying capacity (conveying capacity and conveying distance):

Conveying capacity: The larger the amount of material conveyed per hour (tons/hour or cubic meters/hour), the higher the requirements for belt width, speed, and drive system, and the higher the cost.

Conveying distance: The longer the conveying distance, the more belt length, number of rollers, and drive points (multiple drive units may be required), and the greater the overall investment.

Belt material and specifications

Types of rubber conveyor belts: ordinary cotton canvas core (CC), nylon core (NN), polyester core (EP), steel cord core (ST), etc., among which steel cord core belts have the highest strength and the most expensive price.

Special properties: rubber conveyor belts with special properties such as wear resistance, heat resistance, oil resistance, acid and alkali resistance, flame retardant, and food grade will have higher manufacturing costs and selling prices than ordinary belts.

Belt width and number of layers: The wider the width and the more layers (or the larger the wire rope diameter and the higher the density), the higher the belt price. Rubber conveyor belt cost is often one of the largest parts of the total price of the rubber belt conveyor.

Drive system: Calculate the required power according to the load, distance and speed of the rubber belt conveyor. The greater the power, the higher the price of the motor and reducer. There is a big price difference between ordinary motors and explosion-proof motors, variable frequency motors, etc.

Auxiliary equipment and degree of automation: Auxiliary equipment such as sweepers, guide troughs, and unloading devices will increase costs. Safety protection devices such as deviation switches, pull rope switches, anti-tear protection, emergency stop devices, etc. are necessary configurations to ensure safe operation and will also be included in the cost. Whether the rubber conveyor belt requires automation and control systems such as PLC control, remote monitoring, variable frequency speed regulation, and fault diagnosis systems, the higher the degree of automation, the higher the price.

|

Model |

conveyor belt width (mm) |

conveyor length (m) |

motor power (kW) |

conveyor speed (m/s) |

conveyor capacity (t/h) |

|

B500-6 |

500 |

6 |

2.2 |

0.8~1.6 |

50~100 |

|

B650-10 |

650 |

10 |

3.0 |

0.8~2.0 |

80~150 |

|

B800- 12 |

800 |

12 |

4.0 |

0.8~2.0 |

100~200 |

|

B1000-15 |

1000 |

15 |

5.5 |

1.0~2.0 |

150~300 |

|

B1200-20 |

1200 |

20 |

7.5 |

1.2~2.5 |

200~400 |

Note: Special structures such as inclined type (with sidewall), mobile type (with casters), belt lifting platform, etc. can be customized on demand.

The model parameters of the rubber conveyor belt are the core factors that determine its function and price. Common widths are 500mm, 650mm, 800mm, 1000mm, 1200mm, 1400mm, etc. The larger the bandwidth, the greater the conveying capacity. If you can provide specific requirements (such as: conveying material, bandwidth, length, whether rubber conveyor belt needs to be lifted or moved), etc., we can also provide you with the specific model parameters and prices you need to meet your conveying needs.