Farm feed conveyor belt

Farm feed conveyor belt is a special equipment for farm feed transportation. It is mainly composed of a conveyor belt, a drive device, a tensioning device, etc., which can realize the efficient transmission of feed from the storage area to the breeding area and the processing area.

Conveyor belt width: 300-1000mm

Conveying speed: 0.5-2.5 m/s

What is a farm feed conveyor belt?

Types of farm feed conveyor belts

|

Type |

Picture |

Applicable feed type |

Conveying distance |

Conveying angle |

Structural complexity |

Common application scenarios |

|

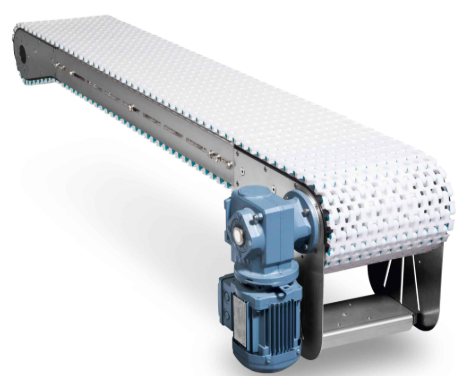

Belt conveyor |

|

Powder, granular, block, wet material |

Long |

Horizontal, inclined |

Low |

Automated feeding system connection, centralized feed distribution, feed processing links, etc. |

|

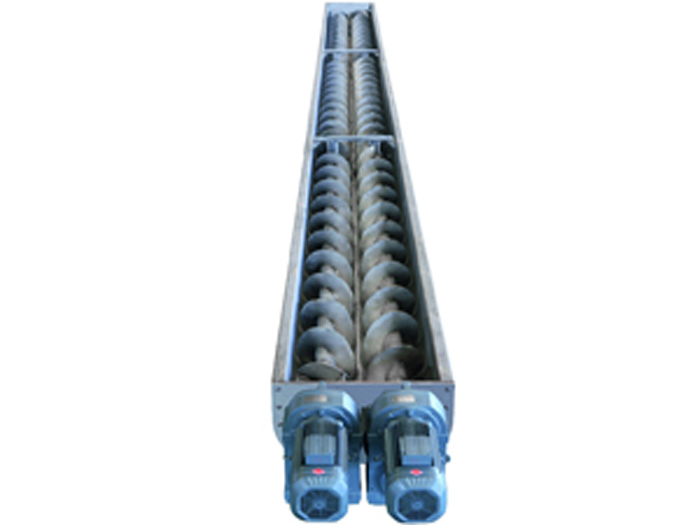

Screw conveyor |

|

Powder, small granular (good fluidity) |

Short |

Horizontal, inclined, vertical |

Medium |

Short distance conveying, lifting, quantitative feeding, connected with silos, mixers and other equipment. |

|

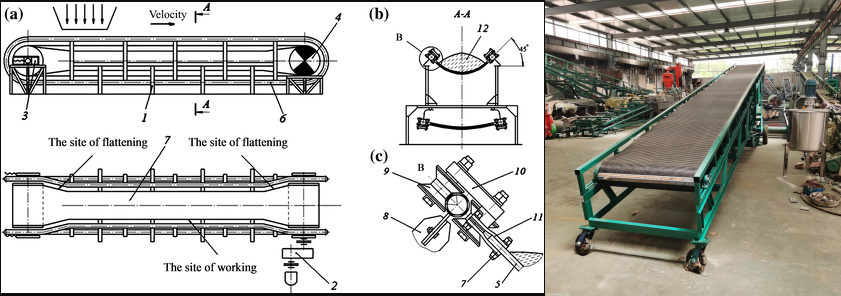

Chain conveyor |

|

Pellets, blocks, wet materials, silage |

Long |

Horizontal, inclined, vertical |

Higher |

Transporting silage, occasions with large conveying volume, connecting large feeding equipment. |

Farm feed conveyor belt video

How does the farm feed conveyor belt work?

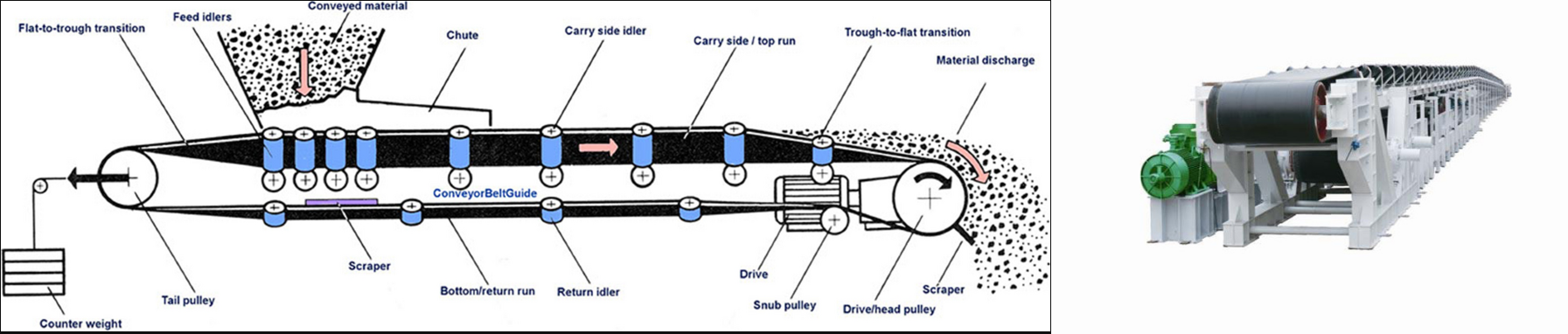

Farm feed conveyor belts rely on motors to drive pulleys to drive the belt forward. When the feed is placed on the belt, the belt drives the feed along a predetermined path. This type of conveyor belt is usually equipped with a guide device to ensure that the belt remains stable during the conveying process. After the belt contacts the conveyed material, it pushes the feed through friction. Driven by the pulley, the belt continues to move forward and transfers the feed from the input end to the output end.

Structural composition of farm feed conveyor belts

The structural composition of different types of farm feed conveyor belts varies, but usually includes the following core components:

Drive: The motor provides the power for the conveyor belt to run, and the reducer reduces the speed of the motor and increases the torque to meet the operating requirements of the conveyor belt.

Coupling or pulley/sprocket: transmits the power of the motor to the drive roller or drive shaft.

Conveying mechanism: conveyor belt (endless belt), drive roller, redirecting roller, idler (support belt), sweeper (remove residue on the belt).

Tensioning device: used to adjust the tension of the conveyor belt or chain, common ones are spiral tensioning, spring tensioning, weight tensioning, etc.

Support device: used to support the conveyor belt, trough and drive mechanism, etc., to ensure the stable operation of the equipment.

Feeding and unloading device: feeding port, unloading port

Safety protection device (optional): emergency stop switch, overload protection device, deviation switch, material level detection device

Core features of farm feed conveyor belt

Semi-automatic conveying: driven by electricity, the feed conveying process can be completed without or with only a small amount of human intervention, significantly reducing labor intensity.

Continuity and stability: designed for uninterrupted or planned continuous feed delivery to ensure timely and stable feeding.

Reduce feed waste: with the help of the automatic control system, feed can be delivered according to the preset amount, reducing leakage and overfeeding caused by manual feeding, and reducing feed costs.

Adapt to a variety of feed types: different types of conveyor belts can adapt to feeds of different forms and characteristics, including powder, granules, blocks, and even silage.

Flexible layout and conveying path: the conveyor belt system can be designed and installed according to the actual layout of the farm, realizing horizontal, inclined or even vertical conveying, overcoming terrain and space limitations.

Durability and easy maintenance: the farm environment is relatively harsh, and the feed may be corrosive to a certain extent, so the conveyor belt is usually made of wear-resistant and corrosion-resistant materials.

Technical parameters of farm feed conveyor belt

|

Model specification |

Conveyor belt |

Conveyor length |

Diameter of drive roller |

Production capacity |

Power (kW) |

Weight |

||

|

Width (mm) |

Speed (m/s) |

inclination angle(°) |

(m) |

(mm) |

(t/h) |

(t/h) |

(t) |

|

|

TD-500 |

500 |

0.8~2.5 |

0~20 |

2~240 |

500, 630 |

40~232 |

1.5~30 |

3.93 |

|

TD-650 |

650 |

0.8~2.5 |

0~20 |

2~240 |

500, 630 |

67~391 |

1.5~45 |

5.1 |

|

TD-800 |

800 |

0.8~3.15 |

0~20 |

2~24 0 |

500, 630 |

118~824 |

2.2~75 |

7.2 |

|

TD-1000 |

1000 |

1~3.15 |

0~20 |

2~240 |

500, 630, 800 |

230~1233 |

4~100 |

9.7 |

Application of farm feed conveyor belts

Farm feed conveyor belts are widely used in modern agriculture, especially in breeding, planting and feed processing plants. They are mainly used to improve work efficiency, reduce manual operations, and ensure the uniformity and accuracy of feed delivery.

1. Feed storage and loading and unloading

Between the feed warehouse or bulk feed transporter and the storage tank, the conveyor belt quickly loads and unloads bulk pellet feed (such as corn kernels, soybean meal) or powdered feed (such as fish meal, additive mixed feed). The transporter is equipped with a top spiral pipe belt with an elevation angle of 60°, which directly pipes the feed to the high-level storage tank.

2. Feed processing and mixing

In feed processing plants or farm-owned feed production lines, conveyor belts are used to feed raw materials (such as grains, soybean meal, vitamin additives) into grinders, mixers or pelletizers. Chain conveyor belts transport corn kernels from the raw material bin to the grinder, and the flow rate can be controlled by variable modulation during the conveying process to ensure the continuity of processing.

3. Feed distribution in farms

In pig farms, poultry farms or aquaculture farms, conveyor belts are used to distribute feed from storage tanks to feeding troughs or automatic feeding systems. Screw conveyors transport pelletized feed from central storage tank pipes to feeding troughs in each pig house. For example, a farm with 1,000 pigs needs to distribute 5 tons of feed per day, and the conveyor belt can complete the distribution within 10 minutes with a capacity of 50 tons/hour.

4. Mobile and temporary applications

In small and medium-sized farms or temporary feed processing scenarios, mobile conveyor belts are used for flexible feed transportation. Wheeled conveyor belts transfer feed piled in the open air to warehouses. For example, a 5-meter long mobile conveyor belt can quickly clean up scattered feed with a capacity of 20 tons/hour.

Farm feed conveyor belt prices

Farm feed conveyor belt prices vary based on a variety of factors, and the specific price depends on the following key factors:

Type and function: Different types of conveyor belts (such as belt type, spiral type, bucket type, scraper type, pneumatic conveying system, etc.) have different price ranges. Additional features, such as automated control systems, intelligent batching systems, timed delivery functions, etc., also affect the price.

Conveying capacity and length: The conveyor belt's load capacity (tons/hour), bandwidth, and conveying distance directly affect the price. Conveyor belts with large conveying volumes and long conveying distances are usually more expensive.

Material and durability: High-quality materials (such as wear-resistant rubber, stainless steel, etc.) and special features (such as anti-corrosion, fireproof, high temperature resistance, etc.) will increase the cost of conveyor belts.

Customization: Custom-designed conveyor belt systems will be relatively expensive. Customized conveyor belts usually need to be designed according to the specific needs of the farm, and the price will fluctuate according to the design complexity and technical requirements.

Farm feed conveyor belt prices vary greatly depending on factors such as type, specification, function, brand, etc. It ranges from a few thousand dollars to tens of thousands of dollars. When purchasing, it is recommended to choose the appropriate conveyor belt according to the needs of the farm (such as conveying capacity, conveying distance, etc.), and discuss the appropriate quotation with DAHAN Machinery Factory. If you have more specific needs or specifications, provide the details and we can help you further analyze the price!