A Fertilizer for Conveyors Belt is a type of material conveying equipment commonly used in fertilizer production and processing. Depending on the structure and application scenario, this equipment can be categorized into various types, including fixed, mobile, and high-angle types. Its conveying capacity and distance can be tailored to meet specific needs, adapting to operations ranging from small production lines to large fertilizer plants. Belt conveyors can handle a variety of fertilizer forms, including powders, granules, and lumps. They are a common method for connecting various equipment in a production line and ensuring material flow.

A Fertilizer for Conveyors Belt has become a crucial component of fertilizer handling systems. Its application solves the problem of transferring large amounts of material during production, storage, and packaging. The specific equipment selection, including the conveyor belt width, material, and drive configuration, must be determined based on factors such as the physical properties of the material, the required conveying capacity, and the site environment. A properly configured belt conveyor is essential for ensuring a smooth production process and continuous material flow.

The unique properties of a Fertilizer for Conveyors Belt enable it to meet the stringent efficiency, output, and material quality requirements of fertilizer production. From continuous conveying to robust handling capacity for large-scale production, to flexibility in complex production environments, belt conveyors demonstrate their vital role in fertilizer production lines. Furthermore, the Fertilizer for Conveyors Belt features a simple structure and easy maintenance.

Efficient and energy-saving: The fertilizer for conveyor belt is driven by an electric motor, which has higher conveying efficiency and energy utilization than manual handling, reducing the waste of manpower and energy.

Large-capacity transportation: Fertilizer for conveyor belts can be designed and customized as needed, which can meet the needs of agricultural production of different scales and achieve large-capacity fertilizer transportation.

Precise control: The fertilizer for conveyor belt can achieve precise control of fertilizers by adjusting the conveying speed and tension to ensure even distribution and delivery of fertilizers.

Adapt to diverse needs: The fertilizer for conveyor belt can adapt to different types and shapes of fertilizers, such as granular, powdery, lumpy, etc., and has strong adaptability.

Reduce human labor: The use of fertilizer for conveyor belts can reduce the workload of manual transportation of fertilizers, reduce labor intensity, improve work efficiency, and reduce the consumption of human resources.

Improve safety: The fertilizer for conveyor belt has a safety protection device, which can effectively prevent fertilizer spillage and environmental pollution, and ensure the safety of workers.

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

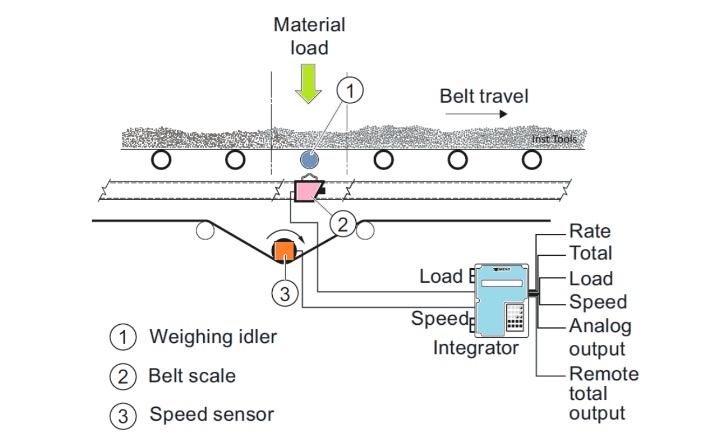

The Fertilizer for Conveyors Belt's operating principle is relatively simple yet effective. A motor drives a conveyor belt, supported by rollers, to circulate, achieving continuous material transport. A belt conveyor primarily consists of several core components: a conveyor belt (typically made of materials such as rubber or plastic, offering a certain degree of flexibility and strength), a drive unit (typically a motor and a reducer), rollers (drive and bend rollers), and rollers. When the equipment starts operating, the motor drives the drive roller, rotating the conveyor belt forward. Fertilizer material falls from the feed port onto the moving conveyor belt, where it is smoothly transported to its destination. At the end of the conveyor, the material passes over the redirecting roller and is discharged by gravity at the discharge port. The entire conveying process is continuous, and the material on the conveyor belt is transported smoothly, avoiding violent bumps and shocks. This effectively protects the integrity of the fertilizer particles and reduces breakage. By adjusting the motor speed, the conveyor belt speed and, therefore, the material conveying capacity can be controlled to meet different production needs.

The Fertilizer for Conveyors Belt is widely used in all aspects of fertilizer production and distribution. Its versatility and high efficiency make it an indispensable piece of equipment in the industry. The following are its main applications:

Raw material transportation: In the early stages of fertilizer production, belt conveyors are used to transport various raw materials from storage warehouses or mining areas to processing or mixing areas. These materials may include mineral raw materials such as phosphate rock, potash, limestone, and dolomite; inorganic materials such as urea, sulfur, and ammonium phosphate; and organic materials such as manure and compost.

In-Line Conveying: In fertilizer processing, belt conveyors are a critical link connecting various production equipment. They can connect equipment such as granulators, coolers, dryers, and screeners to form a continuous, automated production line. For example, they can convey granulated fertilizer pellets to a cooler, or convey screened finished products to the packaging area.

Finished Product Packaging and Storage: After processing, finished fertilizer is transported to the packaging area via belt conveyors. Here, belt conveyors smoothly transport bagged or bulk fertilizer to the packaging machine for weighing and bagging. The finished bags are then transported to a palletizer or directly to the warehouse.

Logistics and Distribution: In logistics, belt conveyors are used to move full pallets or large bags of fertilizer between storage areas, loading docks, and trucks. For large fertilizer ports or transshipment stations, it can be used as part of a fixed or mobile ship loader to load large quantities of bulk fertilizers into cargo ships, improving loading and unloading efficiency.

The Fertilizer for Conveyors Belt is an essential piece of equipment in agricultural production, providing an effective solution for the storage, transportation, and application of fertilizer. This equipment accurately and quickly transports fertilizer from storage to fields or fertilizer application equipment. It can also be used in conjunction with a fertilizer spreader to achieve precise fertilization, meeting the fertilization needs of different crops. The following is a detailed introduction to its key case studies:

Fertilizer storage and transportation: Fertilizer conveyor belts can transport fertilizers from storage locations to farmland or fertilization equipment, reducing the labor intensity and time cost of manual transportation and improving fertilizer utilization efficiency.

Precise fertilization: The fertilizer for conveyor belt can be used in conjunction with fertilization machinery to achieve precise fertilizer delivery. By controlling the speed and amount of the conveyor belt, the fertilization needs of different crops and soils can be realized, and the accuracy and effect of fertilization can be improved.

Farmland improvement: Fertilizer for conveyor belts can transport amendments and organic fertilizers into farmland to help improve soil quality and increase crop yield and quality.

Agricultural waste treatment: Fertilizer for conveyor belts can transport agricultural waste such as straw, livestock and poultry manure, etc. to corresponding processing equipment to achieve resource utilization and environmental protection.

As material handling equipment in fertilizer production lines, manufacturers of Fertilizer for Conveyors Belts typically offer customization capabilities. This capability allows the equipment to precisely match the customer's specific requirements for conveying capacity, material properties, site environment, and degree of automation. This customization capability is first demonstrated in the design phase. Based on the fertilizer type (e.g., granular, powdered, compound fertilizer), material density, moisture content, and other physical properties, the manufacturer will scientifically calculate the required conveyor belt width, belt speed, and motor power to ensure the desired conveying capacity. The next step is material selection. To address the corrosive components in fertilizers, manufacturers offer a variety of corrosion protection solutions, such as corrosion-resistant rubber conveyor belts or stainless steel frames and rollers, to extend the equipment's service life. Furthermore, manufacturers customize the structure based on the site layout. For example, to transport materials between floors, a high-angle conveyor can be designed, equipped with side guards or skirted conveyor belts to prevent material from slipping. In areas with limited space, mobile or telescopic conveyors can be designed to increase equipment flexibility. For workshops requiring dust control, manufacturers can provide fully enclosed designs to effectively control dust spillage. This customization capability is a key measure of a Fertilizer for Conveyors Belt manufacturer's technical strength and service level, ensuring that the equipment not only meets basic conveying functions but also operates stably and reliably in harsh production environments.

In short, fertilizer for conveyor belts, as the source of fertility for agricultural production, provide farmers with efficient and convenient fertilizer transportation solutions. Its application not only improves the efficiency and quality of agricultural production, but also reduces farmers' labor intensity and contributes to the development of agricultural modernization. Choose a fertilizer for conveyor belt to make fertilizer transportation more intelligent and efficient, helping farmers realize their dream of a bumper harvest.