In general, a simple, short-length (such as about 10 feet) belt conveyor may cost around $1,000. For a long-distance, highly customized, and complex belt conveyor system, the price may exceed $10,000 or even higher. Some small, simple home or light industrial belt conveyors may only cost a few hundred dollars; while large belt conveyor systems used in large mines, ports, etc. may cost up to hundreds of thousands of dollars.

Specifications

The length and width of the conveyor belt are important factors affecting the price. The longer the length, the more materials are required, the more complex the manufacturing process, and the higher the price. The wider the width, the more material is used, and a more powerful drive system may be required, and the cost will rise accordingly. For example, the specifications of conventional conveyors range from B500 to B2200, with lengths ranging from 1 meter to several kilometers, and the prices vary greatly.

|

Model (bandwidth) |

Conveyor belt width (mm) |

Conveying length range (m) |

Conveying capacity (t/h) |

Belt speed (m/s) |

Motor power (kW) |

Common application areas |

|

B400 |

400 |

3~30 |

30~60 |

0.8~2.5 |

1.5~7.5 |

Light industry, food |

|

B500 |

500 |

3~50 |

40~80 |

0.8~2.5 |

2.2~11 |

Building materials, logistics |

|

B650 |

650 |

5~80 |

60~150 |

1.0~2.5 |

3~15 |

Chemical industry, metallurgy |

|

B800 |

800 |

10~100 |

80~300 |

1.0~3.15 |

5.5~22 |

Cement plant, wharf |

|

B1000 |

1000 |

15~150 |

150~500 |

1.25~3.15 |

7.5~37 |

Ore, sand and gravel |

|

B1200 |

1200 |

20~200 |

200~700 |

1.25~3.15 |

11~55 |

Coal mine, power plant |

|

B1400 |

1400 |

30~300 |

300~1000+ |

1.25~3.5 |

15~75 |

Port, large conveyor line |

Material quality

The price of conveyor belt varies significantly depending on the material. Common materials include rubber, PVC, polyurethane, fabric and steel cord. Rubber conveyor belts have good durability and flexibility, and are moderately priced; PVC conveyor belts are chemically resistant and are often used in industries such as food processing, and are relatively inexpensive; polyurethane conveyor belts are wear-resistant and oil-resistant, and are relatively expensive; steel conveyor belts are mainly used in heavy-duty situations, have high tensile strength, and are relatively expensive. In addition, the material quality of components such as frames and rollers will also affect the overall price. High-quality steel or aluminum alloy materials will increase the cost.

Drive and control system

Different drive methods have different prices. Common ones include electric roller drives, motor-reducer drives, etc. Complex drive systems, such as those that require frequency conversion speed regulation, servo control, etc., will be more expensive. The more powerful the conveyor, the more powerful the drive equipment required, and the higher the cost. At the same time, advanced control systems, such as those with intelligent monitoring and fault diagnosis functions, will also increase the price.

|

Belt conveyor type |

Typical application |

Reference price range |

|

Simple type (less than 5 meters, PVC belt) |

Packaging line, food sorting |

$500~$2,000 |

|

Standard type (10~20 meters, rubber belt) |

Industrial production line, warehousing and transportation |

$3,000~$8,000 |

|

Reinforced type (20~40 meters, heavy structure) |

Sand, coal, cement plants, etc. |

$8,000~$20,000 |

|

Large customized system (more than 40 meters, multi-point drive) |

Ports, power plants, mines |

$20,000~$50,000+ |

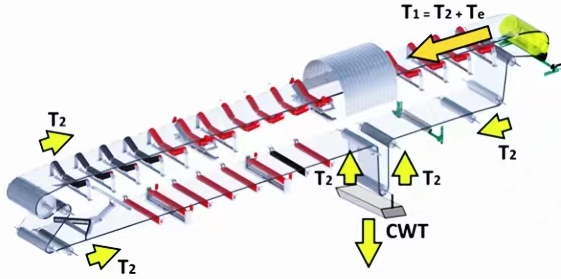

Complexity of structural design

If the user has special requirements, the price will increase accordingly. For example, if special functions such as high temperature resistance, corrosion resistance, and full sealing are required, or if special terrain and environment need to be adapted, such as large-angle climbing and curve conveying, the conveyor needs to be specially designed and manufactured, which will lead to higher costs. Fixed vs. mobile (with casters); whether there are climbing sections, turning sections, telescopic sections; whether there are auxiliary structures such as sweepers, dust covers, and anti-deviation devices; the more complex, the higher the manufacturing and assembly costs.

If you want to know the specific price information first, you need to provide the following information:

Conveying length and width; belt type; material (carbon steel/stainless steel); material type and conveying volume;

Installation site conditions (whether there are legs, mobile requirements); motor and control requirements. If you have specific parameters, we can help you get a more accurate price.

The price of belt conveyor systems varies greatly due to factors such as length, bandwidth, material, drive system, and structural complexity. The price ranges from hundreds to tens of thousands of dollars. Simple types are about $500~$2,000, and heavy-duty customized systems can reach more than $50,000. The specific quotation needs to be determined based on parameters such as conveying length, belt type, material, and control system.