Belt conveyor system is a continuous material conveying equipment widely used in various industrial and logistics scenarios. Its core function is to efficiently and continuously transport bulk materials or packaged items from one location to another. It can adapt to horizontal, inclined and even S-shaped conveying paths with high flexibility. It can handle various materials from fine powders (such as sand and grains) to large pieces of ore or packaged packages.Belt conveyor system is a continuous conveying mechanical equipment, mainly used for the conveying of bulk materials or packaged goods. It occupies an important position in industrial production with its continuous, efficient and flexible characteristics.

Belt conveyor systems come in various types depending on the conveying requirements. Horizontal belt conveyors are suitable for long-distance, high-volume conveying within a flat surface, featuring a simple structure and smooth operation. Inclined belt conveyors are ideal when materials need to be elevated, allowing them to be transported upward or downward by adjusting the inclination angle. Mobile belt conveyors are renowned for their mobility and are particularly suitable for applications requiring frequent changes in work areas, such as ports and storage yards. For conveying materials at high lifts, at large angles, or in challenging environments, hydraulic lift belt conveyors offer greater power and more flexible angle adjustment.

Belt conveyor systems, with their flexibility, play a vital role in industrial production. Belt conveyor systems come in a variety of types, including horizontal, inclined, mobile, and hydraulic, tailored to different application scenarios and conveying requirements. Each type offers unique designs and features to meet diverse material handling challenges.

|

Classification dimension |

Horizontal belt conveyor |

Inclined belt conveyor |

Mobile belt conveyor |

Z-type belt conveyor |

Hydraulic belt conveyor |

|

Picture |

|

|

|

|

|

|

Conveying speed |

0.5-6.0 m/s |

Often lower than horizontal conveying |

Similar to fixed type |

0.2–1.5m/s、10–60 buckets/min |

Usually slower to achieve fine operation |

|

Applicable materials |

Coal, ore, finished goods |

Finished goods |

Bulk materials, finished goods |

Granules、Powders、Fragile items、Sticky materials |

Bulk materials, finished goods |

|

Application range |

Linear conveying within the factory, logistics sorting center, production assembly line |

Material conveying between floors, terrain height difference connection, production line lifting |

Applicable to scenes with frequent changes in work locations |

Food industry、Pharmaceuticals、Agriculture、Chemicals、Packaging lines |

Heavy load start, precise position control, stepless speed change, hazardous environment (explosion-proof) and other special working conditions |

|

Main advantages |

Low cost, wide applicability |

Achieve height difference conveying |

Flexible movement |

Space-efficient、Gentle handling、Hopper or cleated belt options、Sealed construction available |

Precise control, overload protection, can be used in harsh environments |

As a widely used material transmission equipment in the industrial field, the belt conveyor system has many advantages, which makes it perform well in various material handling scenarios.

Continuous and uninterrupted transportation: It can operate continuously for 24 hours, and the materials are continuously transported with the belt without frequent start and stop, which is suitable for continuous operation of the production line (such as food processing lines that transport more than 100 packages per minute).

High-flow conveying capacity: The conveying capacity range is wide, and small systems can transport 5-50 tons per hour (such as warehouse sorting lines), and large-scale mine belt conveyors can reach more than 2,000 tons per hour (such as underground transportation in coal mines).

Adjustable and stable speed: Through frequency conversion control, the speed can be accurately adjusted in the range of 0.5-4 meters per second to match the requirements of different working conditions (such as express sorting lines require low-speed precise positioning, and ore transportation requires high speed and large flow).

Gentle material handling: Compared with some other conveying methods, belt conveyors have less impact and wear on materials. This is especially important for conveying fragile, fragile or high-appearance materials (such as grains, fruits, and packaged products), which helps maintain product integrity and reduce breakage rates.

Belt conveyor system drives the roller through the motor to make the conveyor belt circulate along a fixed path. The material is placed on the conveyor belt and transported from the starting point to the end point as the belt moves. The system can run horizontally or tilted at a certain angle (usually not more than 20°-30°, depending on the characteristics of the material), and loading and unloading are completed by gravity or guide devices.

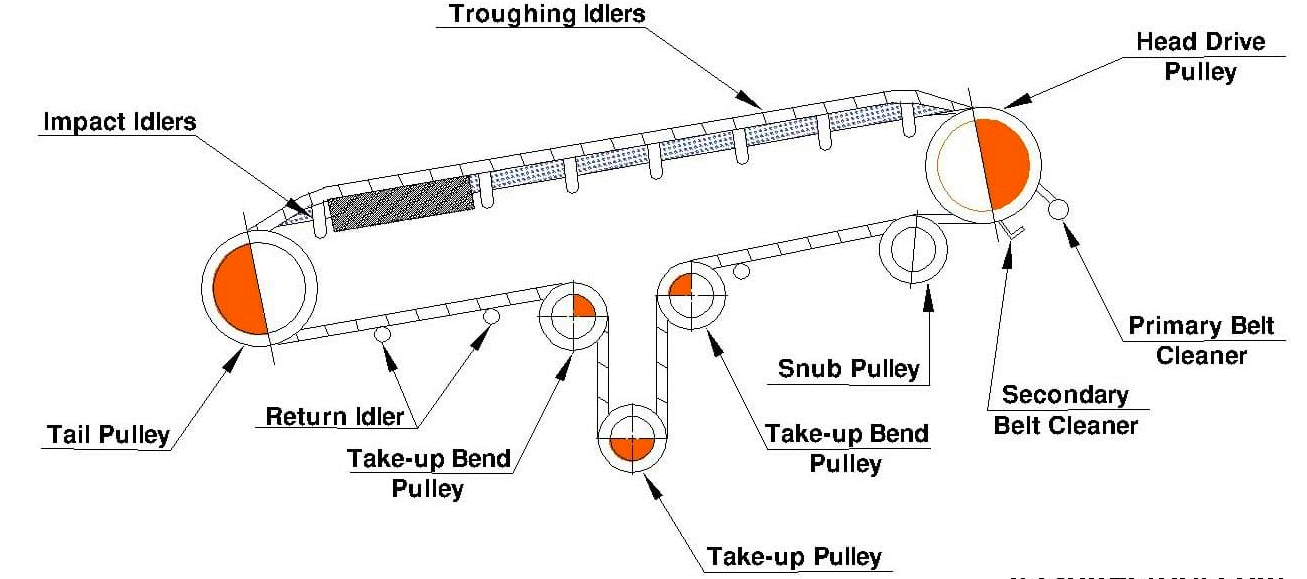

The system mainly consists of several parts working together: the conveyor belt is the main load-bearing and moving component, which forms an endless loop around the driving roller and the driven roller. The drive device (usually a motor and a reducer) provides power to the driving roller to rotate, driving the conveyor belt forward through friction. Rollers or flat support beds are evenly distributed under the conveyor belt to provide support for the conveyor belt and the materials on it to ensure smooth operation. Driven by the conveyor belt, the material is continuously transported from the feed end to the discharge end.

|

Belt width (mm) |

Maximum conveying capacity (t/h) |

Applicable industries |

|

500 |

100~300 |

Belt conveyor system is suitable for light industry, food, chemical industry, small materials |

|

650 |

200~500 |

Belt conveyor system is suitable for grain, building materials, and general bulk material transportation |

|

800 |

400~800 |

Belt conveyor system is suitable for ports, coal mines, and bulk cargo terminals |

|

1000 |

800~1200 |

Belt conveyor system is suitable for mines, metallurgy, and sand and gravel plants |

|

1200 |

1000~1500 |

Belt conveyor system is suitable for large mines, steel, and coal |

|

1400 and above |

1500~5000 |

Belt conveyor system is suitable for ultra-heavy transportation and large-volume port loading and unloading |

The conveyor belt is the core component of the system, usually made of materials such as rubber, plastic or canvas, and is used to carry and transport materials. According to the purpose, it can be divided into general conveyor belts (used to transport bulk materials), patterned conveyor belts (increase friction and prevent materials from slipping), acid and alkali resistant conveyor belts (suitable for special environments), etc.

The driving device includes motors, reducers, couplings, etc., which are used to drive the conveyor belt to operate. The motor reduces the speed and increases the torque through the reducer, and then drives the drive roller to rotate through the coupling, thereby driving the conveyor belt to move.

The rollers are divided into drive rollers, redirecting rollers and tensioning rollers. The drive roller is connected to the drive device to provide power to drive the conveyor belt to operate. The redirecting roller is used to change the running direction of the conveyor belt so that the conveyor belt forms a closed loop. The tensioning roller ensures that the conveyor belt maintains appropriate tension by adjusting the tension to avoid slipping or relaxation.

The tensioning device is mainly used to maintain the tension of the conveyor belt to prevent the conveyor belt from slipping due to insufficient tension or damage to the conveyor belt due to excessive tension. Common ones include heavy hammer tensioning devices (tensioning by the weight of the heavy hammer), spiral tensioning devices (tensioning force is adjusted by spiral mechanism), etc.

Rollers are used to support conveyor belts and materials, reduce the running resistance of conveyor belts, and ensure smooth operation of conveyor belts. They include upper rollers (supporting the conveyor belt in the load-bearing section), lower rollers (supporting the conveyor belt in the return section), self-aligning rollers (preventing conveyor belts from running off track), etc.

Frames and brackets are used to support various components of the entire conveyor system to ensure the stability and reliability of the system.

Belt conveyor systems are widely used in almost all industries that require material handling due to their high efficiency, continuity and flexibility. They are an indispensable part of modern industrial production and logistics.

Package sorting line of e-commerce warehouse: high-speed belt conveyor system cooperates with automatic scanning and sorting equipment to quickly divert packages to different delivery areas according to the destination.

Long-distance transportation in coal mines: Multiple belt conveyor systems are connected end to end to form a transportation line of several kilometers to transport coal from the depths of the mine to the ground.

Continuous ship unloaders at port terminals: Screw or bucket ship unloaders unload bulk cargo onto belt conveyor systems, and then pass through multiple belt conveyor systems to the yard or rear factory.

Assembly line of automobile manufacturing plants: Different types of belt conveyor systems cooperate with automation equipment such as robotic arms to gradually transport automobile chassis, parts, etc. to assembly stations.

Belt conveyor systems are versatile and can transport a variety of bulk materials and piece items. For bulk materials such as coal, ore, and grain, the conveyor belt material can be adjusted to accommodate corrosive, high-temperature environments. For piece items such as boxes and parts, auxiliary devices such as baffles can be added to ensure stable conveying. Belt conveyor system can transport a wide variety of materials, covering various industrial fields.

1. Bulk materials:

Granular materials: such as grains, sand, gravel, coal, ore, fertilizers, salt, sugar, plastic granules, chemical raw materials, etc.

Powdered materials: such as cement, fly ash, flour, milk powder, pigments, powdered medicine, etc.

Block materials: such as coal blocks, ore blocks, stones, wood chips, etc.

2. Piece goods:

Packaged products (such as cartons, bagged materials, barreled materials, canned materials, etc.), regular-shaped items (such as pallets, plates, pipes, etc.), irregular-shaped items (such as auto parts, clothing, packages, etc.)

Belt conveyor systems are the core equipment of modern material transportation. The selection needs to comprehensively consider factors such as working principles, advantages, and applications. If you want to learn more about a certain aspect of the belt conveyor system (such as design parameters, prices, or working principles), you can tell Dahan Machinery's customer service, and we will further refine the answer!

The price of belt conveyor systems varies greatly due to a variety of factors, such as specifications, materials, conveying capacity, configuration requirements, and brands. The longer the conveying distance and the wider the belt, the more steel, belt materials, rollers, and drive devices are required, and the price is naturally higher. Long-distance systems may require multiple drive points and more complex controls.

Small and light belt conveyors are usually used for short-distance, small-batch material transportation, such as small express sorting lines, food packaging conveyors, etc. Its length is generally short, the conveying capacity is relatively small, and the price is usually low; ordinary industrial belt conveyors are a more common type and are widely used in various industrial production scenarios. Its price will vary according to the specific parameter requirements. If the conveying distance is longer, or there are higher requirements for the material and strength of the belt, such as the need for special materials such as wear-resistant, high-temperature-resistant, and tear-resistant belts, the price will increase accordingly.

We have a full range of products from standard flat belt conveyors, trough belt conveyors to inclined/climbing and curved conveyors for special working conditions. Whether you need to convey bulk materials (such as ore, coal, sand, grain) or piece goods (such as packages, boxes), we can provide suitable solutions. We also provide conveyor belts made of various materials such as rubber, PVC, PU, modular plastic mesh belts, etc. that are suitable for special environments such as high temperature resistance, wear resistance, and corrosion resistance.

We can provide comprehensive customization services from design to production. Regardless of the requirements for conveying distance, conveying capacity, and operating speed, or the need for special layout due to limited site space, or even specific requirements for automation control and safety protection.

Belt conveyor systems are widely used in almost all industries that require material handling due to their high efficiency, flexibility and reliability. A large coal mine in Inner Mongolia uses a single conveyor with a length of more than 15 kilometers, achieving seamless connection from the mining area to the coal washing plant.

The conveyor can adapt to the complex terrain changes of the mine, bypass obstacles through horizontal design, avoid material loss and dust pollution caused by multiple transfers, and significantly reduce civil engineering costs.

In addition, some specially customized belt conveyors, such as turning belt conveyors and large-angle belt conveyors, will also be more expensive than ordinary linear ones.