Coal conveyor belt

Coal conveyor belt is a conveying equipment system specially used for transporting coal, raw coal, coke and other combustible solid minerals. It uses the belt as a carrier to transport coal from one location to another, and can meet the needs of long-distance, large-volume and high-efficiency transportation.

Coal conveyor belt width:Up to 2.4m

Coal conveyor belt length:Up to 10,000m

Handling Capacity:Up to 10,000 m³/h

Belt Speed: Up to 6.0m/s

Belt Options:Antistatic, Hard wearing, Fire/Oil /Corrosion resistant

Application: coal mines, thermal power plants, coal washing plants, steel mills, etc.

What is the coal conveyor belt?

Coal conveyor belt is a belt conveying equipment used in coal mining and transportation to transport coal in a continuous manner. It is usually composed of a belt core and a covering layer. The belt core provides strength and flexibility, while the covering layer protects the belt core and prevents coal from wear and corrosion. Coal conveyor belt is driven by a drive device to circulate. In underground coal mines, coal preparation plants, coal terminals and other places, it transports coal from mining faces, storage points, etc. to designated locations, realizing efficient and continuous transportation of coal.

What are the different types of coal conveyor belts?

|

Category |

Type |

Image |

Features |

Typical use cases |

|

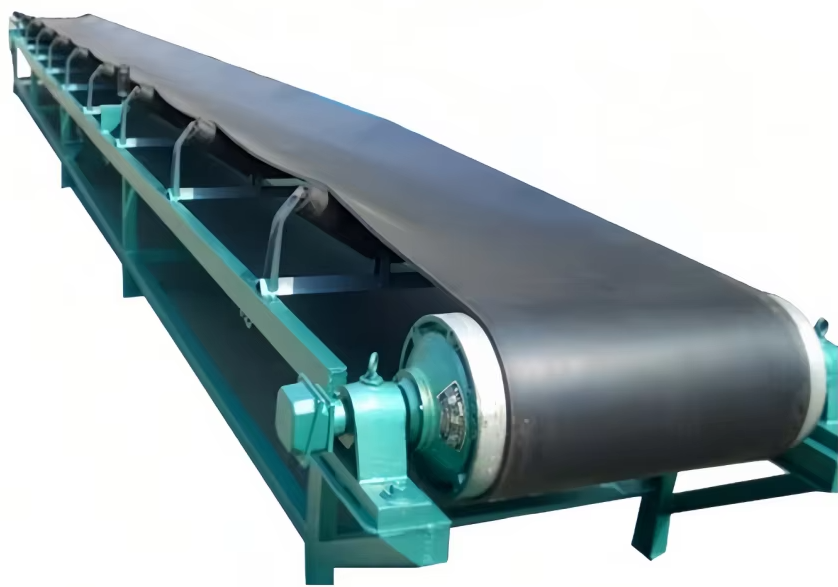

By structure |

Fixed belt coal conveyor |

|

Permanent installation, suitable for long-term operation |

Power plants, coal processing plants |

|

Mobile coal conveyor |

|

Movable, flexible layout |

Temporary yards, loading and unloading areas |

|

|

Telescopic coal conveyor |

|

Can be extended or retracted to reach different distances |

Truck/ship loading |

|

|

Inclined coal conveyor |

|

Designed for vertical or inclined coal transportation |

Underground mines, hills Mausoleum area |

|

|

By belt material |

Cotton (canvas) coal conveyor belt |

|

Low cost, low strength |

Light, short distance |

|

Nylon (NN) coal conveyor belt |

|

High strength, good flexibility |

Medium/long distance, standard transportation |

|

|

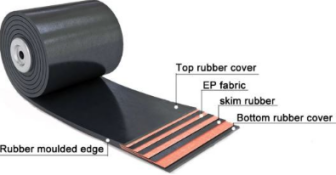

Polyester (EP) coal conveyor belt |

|

Low elongation, moisture and heat resistance |

Wet environment (such as coal washing) |

Coal conveyor belt video

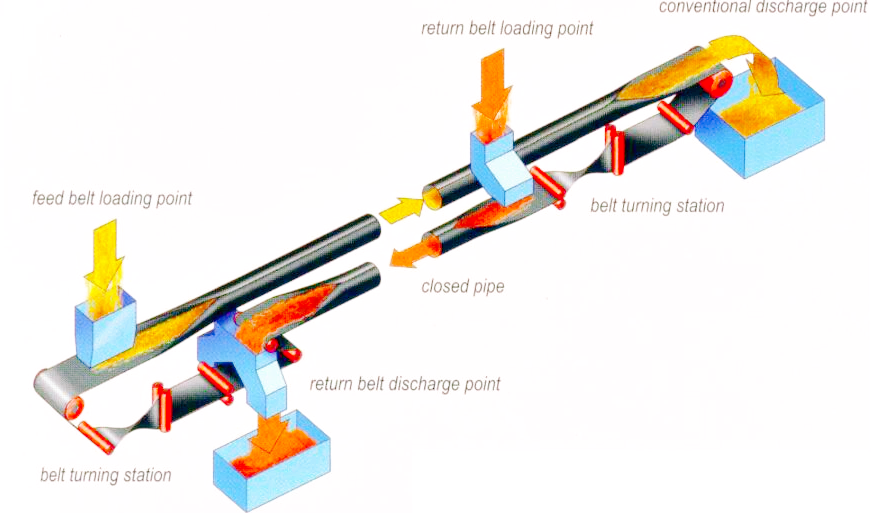

How does the coal conveyor belt work?

Coal conveyor belts transport coal based on continuous cyclic motion. The specific process is as follows:

Starting phase: Coal is placed on the conveyor belt, and the drive roller drives the conveyor belt through friction.

Transportation phase: The conveyor belt, supported by rollers, transports coal from the loading point to the destination, such as from the mine to the ground, or transports coal between different processing equipment.

Unloading phase: At the unloading point, the coal is unloaded from the conveyor belt, completing the transportation process.

What are coal conveyor belt made of?

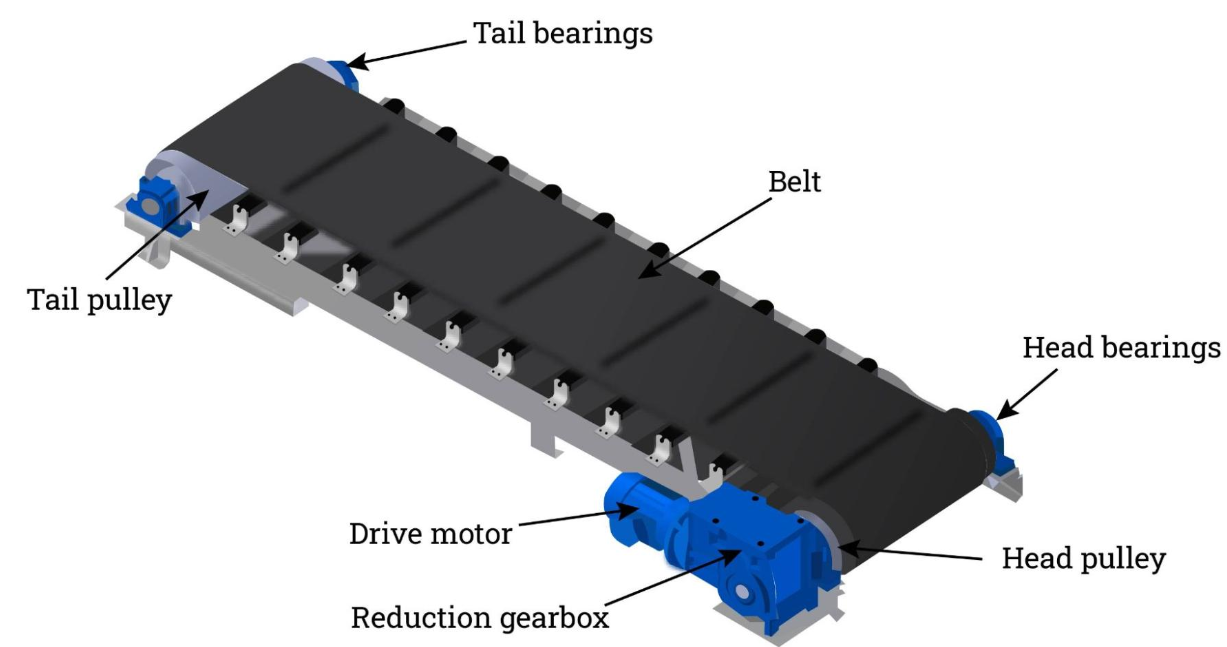

Coal conveyor belt is mainly composed of the following parts:

Belt body: the main part that carries coal, made of materials such as canvas belt or steel cord belt, responsible for carrying coal.

Drive device: provides power, usually composed of electric motor, reducer and drive roller.

Tensioning device: maintains the appropriate tension of the belt body, ensures that the conveyor belt has a certain initial tension at the separation of the drive roller to prevent slipping.

Supporting device: such as roller group, supports the conveyor belt, reduces running resistance, and keeps the belt body stable.

What are the advantages of coal conveyor belts?

Solve the problem of material return

Fine coal particles adhering to the coal conveyor belt after unloading will fall off along the return journey, resulting in material loss and dust generation. Primary and secondary belt cleaners installed at the unloading point can remove coal remaining on the belt surface.

Deal with coal scattering and blockage

Coal may fall off the edge of the conveyor belt during transportation, causing resource waste and equipment damage. Use coal conveyor belts with skirt conveyor belts or sidewall belts to prevent material leakage, and install sweepers and guide chutes to avoid blockage and accumulation of residual materials.

Solve the problem of impact damage

Large pieces of coal falling on the belt, especially at the loading point, will cause impact damage, resulting in tearing and premature failure. Installing impact-absorbing rollers or brackets in the loading area can help cushion the impact of the coal conveyor belt and protect the belt.

Adapt to complex conveying conditions

Coal conveyor belts with patterned conveyor belts or skirt conveyor belts can achieve large inclination angles (up to 90 degrees). Long-distance (several kilometers) transportation can be achieved through multiple conveyor belt relays or intermediate drives.

Technical specifications of coal conveyor belt

|

Parameters |

Specifications/Descriptions |

Parameters |

Specifications/Descriptions |

|

Belt width |

500mm-2400mm |

Conveying capacity |

500-10000t/h |

|

Belt speed |

1.0-4.0 m/s |

Belt material |

Rubber, PVC, steel wire rope core, fabric core |

|

Tensile strength |

500-8000 N/mm |

Drive power |

10kW-2000kW |

|

Conveying length |

Single machine can reach more than 10 km, system splicing can reach tens of kilometers |

Inclination |

0°-30° |

|

Roller type |

Parallel rollers, grooved rollers, self-aligning rollers, buffer rollers |

Roller diameter |

89mm, 108mm, 133mm, 159mm, etc. |

|

Drum diameter |

400mm-1600mm |

Safety device |

Deviation switch, pull rope switch, speed monitor, anti-skid device, emergency stop button |

Application of coal conveyor belts

Coal conveyor belts are widely used in underground mining, surface transportation, coal preparation plants, coal docks and other places. Underground, it transports the coal mined by the coal mining machine from the working face to the pit bottom yard; above the pit, it transports the coal from the wellhead to the coal preparation plant for processing, or directly transports it to coal storage sites or transportation terminals such as railways and ports, so that the coal can be transported to various places.

|

|

|

|

|

Coal-fired Conveying System In Thermal Power Plant |

Storage Yard Transfer Conveying System In Port |

Raw Material Conveying System In Steel Mill |

|

|

|

|

|

Long Distance Conveying System In Open-pit Mine |

Bulk Material Conveying System In Cement Plant |

Sand-Aggregate Conveying System In Crushing Station |

Coal conveyor belt price

Coal conveyor belt prices vary depending on specifications, material and application requirements.

Basic rubber conveyor belts: $20 to $100 per meter for standard coal conveyor belts.

Flame retardant or anti-static belts: $50 to $200 per meter, required for underground coal mines.

Wire cord conveyor belts: $100 to $400 per meter for high capacity, long-distance systems.

My whatsapp: +86 15236742901,e-mail: sale@xxdahan.com

For exact pricing, please contact a Dahan supplier and provide your specifications (belt width, length and coal type).