Food grade conveyor belt

Food grade conveyor belt is a key equipment in food processing, packaging, catering and other industries. It is used to safely and hygienically transport various food raw materials, finished products or packaging materials. Its core requirements include non-toxicity, washing resistance and pollution prevention.

Product description:

Food grade conveyor belt is a type of conveyor belt designed for food processing, packaging, handling and other links. The focus is on safety, hygiene and easy cleaning to ensure that food will not be contaminated. It is widely used in many fields in the food industry, such as meat, aquatic products, baking, fruits and vegetables, dairy products, frozen food, beverages, etc.

Classification of food grade conveyor belts

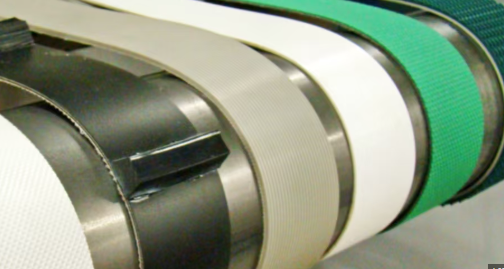

Classification by material:

|

Material type |

Picture |

Features |

Applicable scenarios |

|

PU food grade conveyor belts |

|

Abrasion-resistant, oil-resistant, hydrolysis-resistant, easy to clean |

Bread, candy, meat processing |

|

PVC food grade conveyor belts) |

|

Low cost, acid and alkali resistant, can be designed with anti-slip patterns (need to confirm that there is no plasticizer migration) |

Fruit and vegetable sorting, packaging lines |

|

Silicone food grade conveyor belts |

|

High temperature resistant (-60°C~250°C), non-toxic and odorless, suitable for direct contact with food |

baking, high-temperature sterilization and transportation |

|

PE food grade conveyor belts |

|

Lightweight, anti-stick, commonly used in modular plastic belts |

Frozen food, seafood transportation |

|

Stainless steel food grade conveyor belts |

|

High temperature resistant, corrosion-resistant, easy to disinfect, suitable for extreme hygiene requirements |

Canned sterilization, fried food production line |

Classification by use:

There are various types of food grade conveyor belts to choose from, each designed for specific uses:

Modular belts: These belts are made of interlocking plastic modules, which are flexible and easy to clean. They are ideal for curved conveyors and applications that require complex movements.

Flat belts: Flat belts are a simple, versatile belt suitable for transporting a wide range of food products. They are usually made of materials such as polyurethane or polyvinyl chloride.

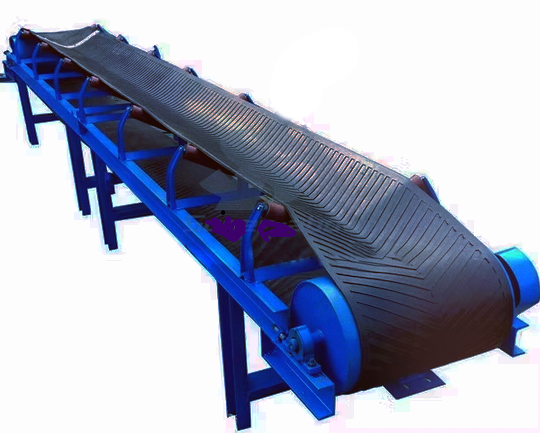

Cleat belts: These conveyor belts are equipped with cleats or raised edges to prevent items from sliding or rolling off, and are suitable for uphill or downhill transportation.

Specialty belts: These belts are designed to meet specific food processing needs, such as metal detection compatibility or high temperature resistance.

Food grade conveyor belt video

Food grade conveyor belt characteristics

Food contact safety: The material needs to be food grade certified (such as FDA, EU 1935/2004), non-toxic, odorless, and does not release harmful substances.

Easy to clean: The surface is smooth or has a self-cleaning design to reduce bacterial growth and support CIP (in-place cleaning) systems.

Corrosion resistance: It can resist oils, acids, alkalis, salts or detergents in food.

Temperature preference: Choose high temperature resistance (such as baking) or low temperature resistance (such as freezing) materials according to the process.

Antibacterial: Some pipeline belts have antibacterial coatings added to inhibit the growth of bacteria.

High friction/low friction: Select according to the conveying characteristics, such as high friction is suitable for pipelines, and low friction is suitable for smooth sliding.

Technical parameters of food-grade conveyor belts

|

Parameter classification |

Parameter items |

Technical indicators/options |

Remarks |

|

Basic material |

Material type |

PU / PVC / Silicone / PE / Stainless steel food grade conveyor belt |

PU and silicone food grade conveyor belts are preferred |

|

Basic material |

Color |

White (standard), blue, green (anti-fouling and visible) |

White is the most commonly used, meeting the visual requirements of food hygiene |

|

Physical properties |

Thickness |

0.5~10 mm (PU/PVC commonly used 1~3mm, stainless steel mesh belt 1~5mm) |

Select according to the load, thick belts are wear-resistant but have reduced flexibility |

|

Physical properties |

Tensile strength |

5~50 N/mm² (PU is the highest) |

For high strength requirements, choose steel wire reinforced type |

|

Physical properties |

Temperature range |

-40°C~250°C (Silicone is the widest, PU is usually -20°C~80°C) |

For ultra-low temperature, choose PE, for high temperature, choose silicone or stainless steel |

|

Physical properties |

Surface treatment |

Glossy/patterned/anti-stick coating (Teflon)/antibacterial coating |

Anti-stick is used for dough and candy, antibacterial is used for fresh food |

Application of food grade conveyor belts

Food processing: Food grade conveyor belts are widely used to transport raw materials from one place to another, such as conveying flour, cereal, vegetables and other raw materials from one end of the production line to the feed port of the processing equipment.

Food packaging: Food grade conveyor belts are used to transport processed food products from the output port of the packaging machine to containers such as packaging boxes and bags, realizing the automated assembly line operation of food packaging.

Food testing: Food grade conveyor belts are also used to transport packaged food products to the quality inspection link, and through the operation of the conveyor belt, the automated detection and sorting of food products can be realized.

Freezing process: Food grade conveyor belts are used to transport food products from the processing stage to the freezer, realizing the automated freezing process of food products.

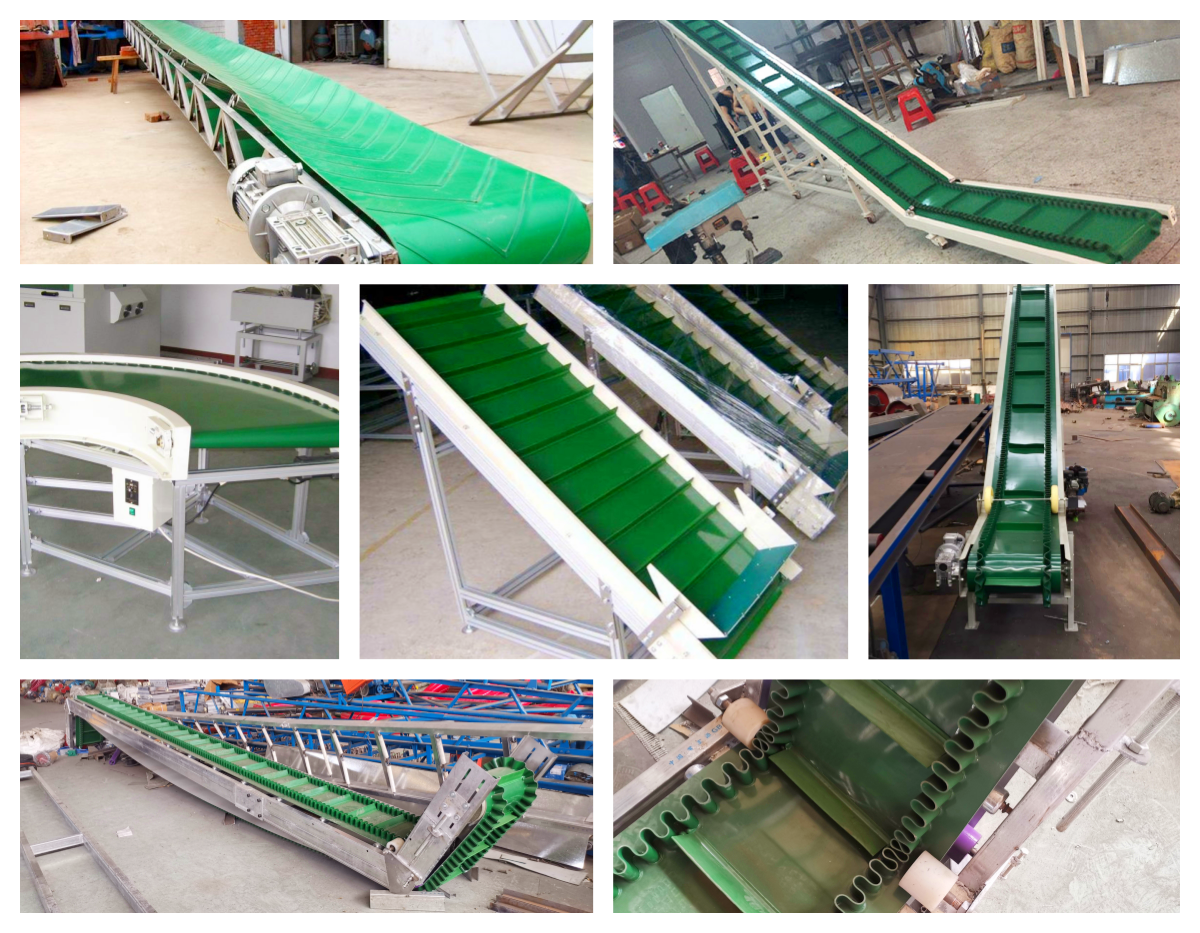

Food grade conveyor belt customer cases

|

|

|

|

|

Baking |

Meat, poultry and seafood processing |

Fruit |

|

|

|

|

|

Vegetables |

Prepared food |

Beverage industry |

Food grade conveyor belt supplier

Dahan Machinery Co., Ltd. is a company specializing in the research and development and manufacturing of conveying equipment. It provides a variety of food-grade conveyor belt products, which are widely used in food processing, packaging, cold chain transportation and other fields.

Various materials: PU, PVC, silicone and other food-grade materials are provided, which meet the food safety standards of FDA, EU and other countries.

Structural customization: Various structural forms such as flat belts, sidewall belts, skirt belts can be customized according to customer needs.

Wide application: Suitable for a variety of food processing scenarios such as meat, fruits and vegetables, baking, dairy products, etc.

Easy to clean: The surface is smooth, oil-resistant and water-resistant, easy to clean and maintain, and meets the hygiene requirements of the food industry.

My whatsapp: +86 15236742901

e-mail: sale@xxdahan.com

For detailed product parameters, quotations or customized solutions, it is recommended to contact the sales team of Dahan Machinery directly to obtain professional technical support and services.