Heavy duty conveyor belt

Heavy duty conveyor belts are important material conveying equipment in the heavy industry field. They have strong load-bearing capacity, good wear resistance, and outstanding impact resistance. They can meet the needs of high-intensity, long-distance, and large-volume continuous operations.

Price range: $400 to $20,000 USD

Belt width: up to 2.4m

Belt length: up to 10,000m

Processing capacity: up to 10,000 m³/h

Belt speed: up to 6.0m/s

What is a heavy duty conveyor belt?

Heavy duty conveyor belt is one of the best choices for bulk material handling equipment. It is able to continuously transport materials from one place to another. Heavy duty conveyor belts can transport any type of bulk material, whether it is powder, granular, block or bagged, whether it is sticky or non-sticky, and are suitable for almost all industrial fields. Especially in situations where there is a large impact force, long distance, large inclination angle or high wear resistance requirements.

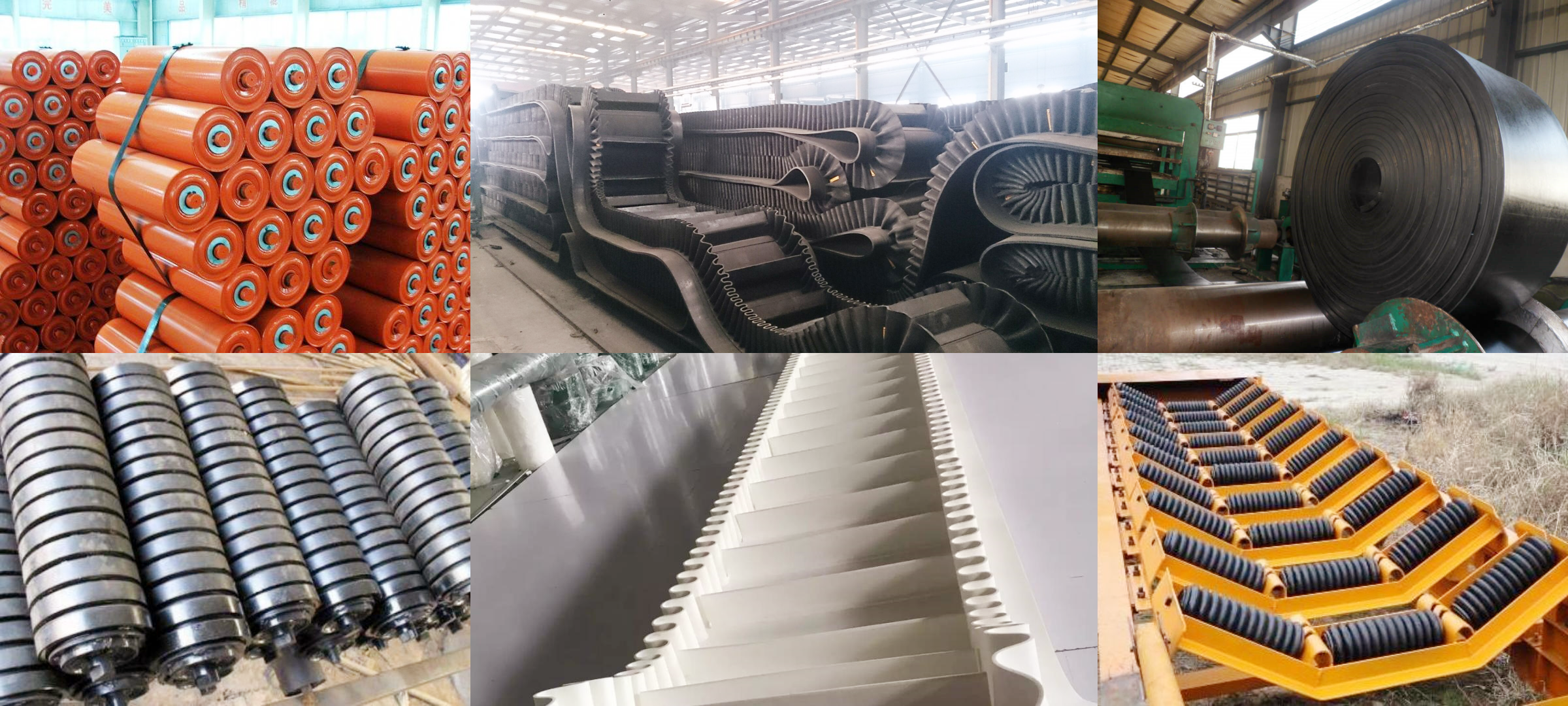

Heavy duty conveyor belts are designed to handle bulky, high-density, and abrasive materials. Compared to conventional conveyor belts, heavy-duty conveyor belts feature significantly enhanced structure and materials. They typically utilize multiple layers of high-strength steel cord or polyester canvas as the belt core, covered with a special rubber outer layer that is wear-, cut-, and impact-resistant. This design enables them to withstand significant tension and impact forces, ensuring stable operation in harsh working conditions such as mines, docks, and large aggregate plants.

Heavy duty conveyor belt video

What are the characteristics of Heavy duty conveyor belt?

Heavy duty conveyor belts can be equipped with various types of self-aligning rollers to effectively prevent the belt from running off track

Smooth operation, no relative movement between the material and the heavy duty conveyor belt, preventing material scattering and damage

A skirt is provided at the feed point and a fully sealed wind hood is provided at the head to improve the working environment

Various types of protection switches provide early warnings for possible accidents and protect components from damage

Heavy duty conveyor belts adopt a modular design, and spare parts are interchangeable, reducing procurement costs

Quick replacement of spare parts for heavy duty conveyor belts greatly reduces expensive downtime

Technical parameters of heavy duty conveyor belts

|

Belt Speed(m/s) Handling Capacity(m3/h) Belt Width (mm) |

0.8 |

1.0 |

1.25 |

1.6 |

2.0 |

2.5 |

3.15 |

4.0 |

5.0 |

6.3 |

|

400 |

41 |

51 |

64 |

82 |

103 |

|

|

|

|

|

|

500 |

69 |

87 |

108 |

139 |

174 |

217 |

|

|

|

|

|

650 |

127 |

159 |

198 |

254 |

318 |

397 |

|

|

|

|

|

800 |

199 |

248 |

310 |

398 |

497 |

621 |

783 |

|

|

|

|

1000 |

324 |

405 |

507 |

649 |

811 |

1014 |

1278 |

1622 |

|

|

|

1200 |

|

594 |

742 |

951 |

1188 |

1485 |

1872 |

2377 |

2971 |

|

|

1400 |

|

825 |

1032 |

1321 |

1651 |

2064 |

2601 |

3303 |

4129 |

|

|

1600 |

|

|

|

|

2185 |

2732 |

3442 |

4371 |

5464 |

|

|

1800 |

|

|

|

|

2795 |

3493 |

4402 |

5590 |

6987 |

9083 |

|

2000 |

|

|

|

|

3467 |

4334 |

5461 |

693S |

8668 |

11277 |

|

2200 |

|

|

|

|

|

|

6841 |

8687 |

10859 |

14120 |

|

2400 |

|

|

|

|

|

|

8286 |

10522 |

13152 |

17104 |

Note: The handling capacity is calculated based on horizontal conveying, running stacking angle of 20°, and roller groove angle of 35°.

The difference between heavy duty conveyor belts and light duty conveyor belts

Heavy duty conveyor belts and light-duty conveyor belts have significant differences in structure, materials, application scenarios and load-bearing capacity. They are each designed for different material conveying needs.

Heavy duty conveyor belts are mainly used for high-strength, large-volume, heavy-load material transportation.

Structure and materials: Usually a multi-layer high-strength fabric core is used as the skeleton material, and a thicker wear-resistant rubber layer or special synthetic material is covered. These materials give it excellent tensile strength, impact resistance, abrasion resistance and tear resistance. For example, heavy duty belts used in scenarios such as mines may contain steel wire rope cores to provide extremely high load-bearing capacity and impact resistance.

Carrying capacity and conveying volume: The carrying capacity is extremely strong, and large, heavy, and highly abrasive materials such as ore, coal, cement, sand and gravel can be conveyed.

Application scenarios: Widely used in heavy industrial fields such as mining, steel, cement, electricity, ports, metallurgy, and large logistics centers for conveying and sorting heavy pallet-type goods.

Light conveyor belts are mainly used for light-load, medium-low-speed, and automated assembly line material transportation.

Structure and materials: Light conveyor belts are usually made of synthetic materials such as PVC, PU, PE, and silicone, and the skeleton is mostly single-layer or double-layer fabric.

Carrying capacity and conveying volume: Mainly used to convey light and small items such as food, medicine, electronic products, cartons, parcels, plastic parts, etc. Its conveying volume is relatively small.

Application scenarios: Widely used in food processing, electronics, medicine, light industry, logistics distribution, agriculture, airport baggage handling and other industries, as well as various automated production lines and packaging lines.

Suitable materials for heavy duty conveyor belt

Heavy duty conveyor belts are designed to handle large volumes of heavy, abrasive, or bulky materials in demanding industrial applications. Their robust construction and specialized materials make them suitable for a wide range of materials, including but not limited to:

|

Aggregates, Frac Sand, Gypsum, Limestone, Clinker, Gravel, Slag, Filter Dusts |

|

Coal, Lignite, Copper Ore, Iron Ore, Nickel, lithium Ore, Alumine, Gold Ore, Zinc Ore |

|

Animal Feeds, Grain, Salt, Sugar, Biomass Fuel, Municipal Waste, Sewage Sludge, Woodchips |

|

Fertilizer, Urea, Inorganic Chemicals,Organic Chemicals, Petroleum Coke, Potash, Pulp & Paper |

What are the applications of Heavy duty conveyor belt?

Heavy duty conveyor belts are essential for industries that need to transport large quantities of heavy, abrasive or bulky materials under harsh conditions. Heavy duty conveyor belts have rugged structure and specialized materials can meet a variety of application needs, including: coal conveying systems in thermal power plants, port yard transfer conveying systems, steel mill raw material conveying systems, open-pit mine conveying systems, cement plant bulk material conveying systems, sand and gravel aggregate conveying systems.

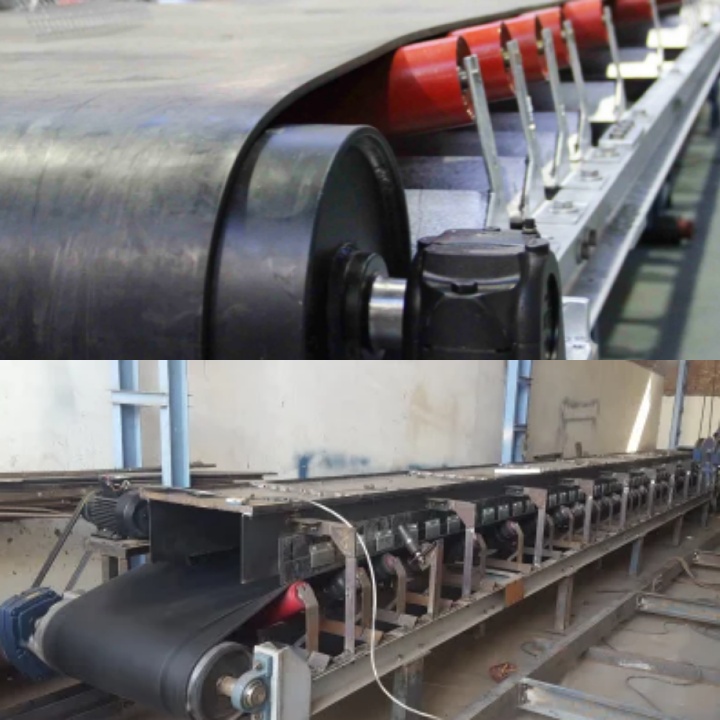

What is the structure of a heavy duty conveyor belt?

The heavy-duty conveyor consists of conveyor belts, rollers, idlers, frames, tensioning devices, drive devices, protective switches and other components.

The heavy-duty conveyor belt transports various materials through rubber conveyor belts. The conveyor belt is installed on heavy-duty trough idlers with an inclination range of 20°-45°, and each idler is installed on a steel idler bracket. The belt conveyor can transport materials at various inclination angles, usually between 0°-25°.

Heavy Duty Conveyor Belt Customer Cases

In thermal power plants, heavy duty conveyor belts transport coal from the unloading point to the boiler. They need to withstand high-intensity, long-term continuous operation to transport large amounts of abrasive coal. These conveyor belts usually have high tensile strength and can cope with long-distance and large-angle transportation needs.

Ports are distribution centers for various bulk goods, such as iron ore, coal, and grain. Here, heavy duty conveyor belts are responsible for efficiently and quickly transferring unloaded materials from the dock to the yard, or loading them from the yard. Due to the huge material throughput and the possibility of sharp and heavy blocks, the conveyor belts need to have excellent wear resistance, impact resistance, and tear resistance to ensure reliability under frequent loading and unloading and high-load operation.

The production process of steel plants has extremely high requirements for material transportation. From raw materials such as iron ore, coke to limestone, heavy duty conveyor belts are required to transport them uninterruptedly. These materials are usually dense, abrasive, and may be at high temperatures.

|

Coal-fired Conveying System In Thermal Power Plant |

Storage Yard Transfer Conveying System In Port |

Raw Material Conveying System In Steel Mill |

|

|

|

|

|

Long Distance Conveying System In Open-pit Mine |

Bulk Material Conveying System In Cement Plant |

Sand-Aggregate Conveying System In Crushing Station |

|

|

|

|

Material transportation in open-pit mines is often a challenge of ultra-long distances and large volumes. Conveyor belts need to have extremely high tensile strength, be able to cross complex terrain, withstand extreme climatic conditions and continuous high-load impact, and ensure stable and efficient output of ore or waste rock.

The production of cement plants is inseparable from the transportation of bulk materials such as limestone, clay, clinker and cement. Heavy duty conveyor belts are responsible for all links from raw material crushing, pre-homogenization to clinker transportation and cement product packaging. Because the material is dusty and abrasive, and the clinker may have high temperature, the conveyor belt must have excellent wear resistance, dust resistance, and even high temperature resistance to ensure the continuity and stability of the production line.

In the sand and gravel aggregate production line, the stone processed by the crushing station has different volumes and weights, and sharp edges and corners, which cause great wear and impact on the conveyor belt. Heavy duty conveyor belts are key equipment connecting crushers, screens and yards, and need to be able to withstand strong impacts and heavy wear.

Heavy duty conveyor belt supplier

Dahan Machinery's heavy-duty conveyor belts are designed to meet the demanding requirements of medium to heavy-duty applications. We stock a variety of conveyor belt materials and can be shipped to your facility immediately. With multiple full-time teams and over 30 years of combined experience in heavy duty conveyor belt installation, your company will be able to fully trust our team to provide you with industry-leading service.