Heavy duty conveyor belt for coal is a high strength rubber conveyor belt specially designed for the characteristics of coal materials. It is widely used in coal mining, coal preparation plants, thermal power plants and coal logistics systems. Because coal has the characteristics of large block size, sharp edges and corners, high specific gravity, and easy to generate dust, the conveyor belt has high requirements for wear resistance, impact resistance and tensile strength during transportation.

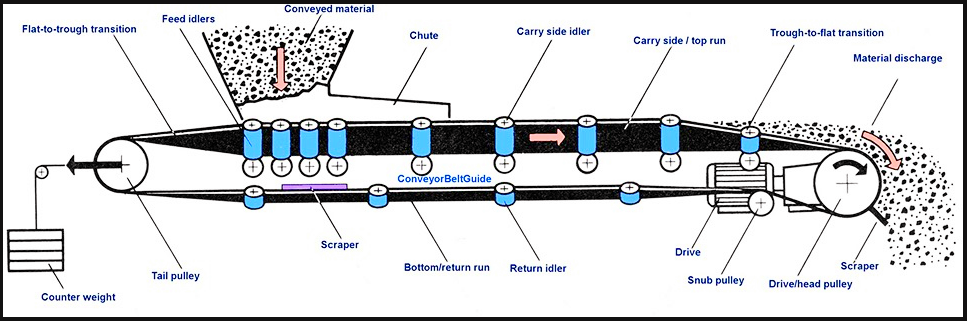

Heavy duty conveyor belts usually use multi layer polyester canvas or steel wire rope as the skeleton material, covered with wear resistant rubber layers on the top and bottom. They have the advantages of strong structure, large conveying capacity, stable operation, etc., and are suitable for long distance, large volume continuous conveying tasks. Some coal mine underground environments also need to use special conveyor belts with flame retardant and antistatic properties to meet the needs of safe production.

|

Project |

Heavy duty belt conveyor |

Screw conveyor |

Bucket elevator |

|

Picture |

|

|

|

|

Applicable occasions |

Main transportation system on the ground or underground, long distance transportation |

Local transportation, pulverized coal transportation, auxiliary feeding |

Vertical or high angle lifting, such as coal bunker feeding |

|

Conveying material type |

Raw coal, large coal, coal powder |

Coal powder, crushed coal, dry coal slime and other fine grained materials |

Raw coal, crushed coal, coal slag, etc. |

|

Conveying direction |

Horizontal or small inclination (generally ≤18°) |

Horizontal or small inclination |

Vertical or large inclination (generally ≤60°) |

|

Conveying distance |

Long |

Short (generally <30 meters) |

Short to medium (generally <50 m) |

|

Conveying capacity |

large |

small |

medium |

|

Structural features |

continuous belt drive, large load capacity |

spiral push material in closed pipe trough or U shaped trough |

hopper vertically lifts material along belt or chain |

|

Common locations |

main transport lane, ground belt corridor |

local feeding, clearing, etc. on the ground or underground |

ground coal bunker, coal distribution system |

|

Typical equipment |

EP conveyor belt, steel cord belt conveyor |

U shaped screw conveyor, tubular screw conveyor |

plate chain, ring chain, belt hoist |

Heavy duty conveyor belt for coal is made of multi layer fabric (such as EP, NN) or steel wire rope as skeleton material, and natural rubber or synthetic rubber as covering layer. It has good tensile strength, wear resistance, impact resistance and other properties, and is suitable for conveying large coal, raw coal, coal powder and other materials.

Skeleton layer: determines the strength and tensile properties of the conveyor belt. Common materials include: EP canvas (polyester/nylon): high strength, small elongation, good heat resistance; NN canvas (nylon/nylon): good elasticity and strong impact resistance; Steel cord core: used for ultra long distance, high tension conveying system.

Covering rubber layer: covers the upper and lower surfaces of the conveyor belt, used to protect the skeleton layer and contact with the material. Its performance affects the wear resistance and corrosion resistance of the conveyor belt. The upper covering layer is used to contact the material and requires wear resistance; the lower covering layer is used to contact the roller and requires wear resistance and bending resistance.

Edge rubber and core rubber: strengthen the bonding performance between the belt edge and each layer to prevent interlayer debonding, cracking and other problems.

Steel cord core conveyor belt: Given its excellent strength, the overall thickness of the steel cord core conveyor belt is usually around 15 mm to 30 mm, or even thicker, depending on the strength grade and the thickness of the covering rubber. For example, a steel cord conveyor belt of ST2000 may be around 20mm, while ST4000 or higher may be thicker.

Fabric core conveyor belt (such as EP belt): The thickness of fabric core conveyor belts ranges widely, from a few millimeters to tens of millimeters.

① Light or medium coal transportation (short distance, small transportation volume): may be around 8mm to 15mm.

② Heavy coal transportation (long distance, large transportation volume): may reach 18mm to 30mm or even thicker, especially multi layer EP fabric core belt.

Xinxiang Dahan Machinery Co., Ltd. provides belt conveyors of various specifications, and the price range is usually between 5,000 yuan and 50,000 yuan. The specific price depends on the model, conveying length, conveying volume, material and other factors of the conveyor. Due to the diversity of product configurations, it is recommended that you contact Dahan Machinery directly to obtain an accurate quotation for your needs.

Provide specific working parameters (transportation volume, inclination, particle size, environmental conditions) to the sales department of Dahan Machinery

Inquire about the price of specific products through the website's online customer service, message, etc.

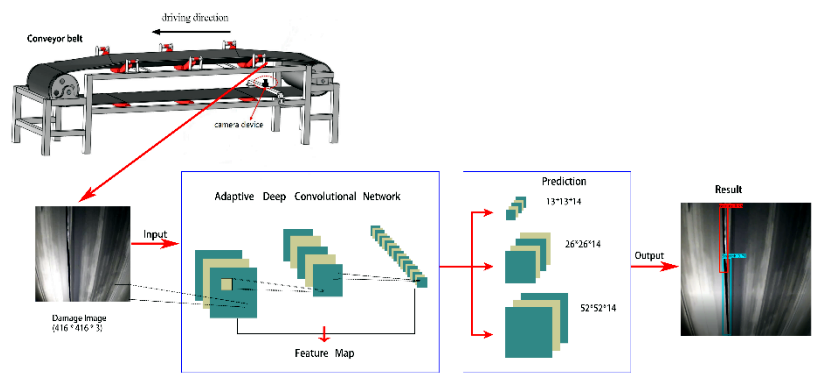

As a bulk material, coal has the characteristics of high density, uneven particles, and easy wear equipment. During mining, transportation and processing, special conveying equipment is required. Heavy duty conveyor belts for coal are special conveying equipment designed for these characteristics. They use high strength skeleton materials such as steel wire ropes and polyester canvas, which can withstand the heavy pressure and impact of coal and achieve large volume and long distance transportation. In short, heavy duty conveyor belts for coal are indispensable and important equipment in the coal industry, and their performance directly affects the efficiency and safety of coal transportation.