Portable belt conveyor

What is Portable belt conveyor?

Portable belt conveyors can be categorized into several main types depending on their specific needs: movable belt conveyors, typically equipped with wheels for easy movement over short distances on flat surfaces; hydraulic lift belt conveyors, whose height and angle can be adjusted hydraulically; and folding/telescopic belt conveyors, whose design allows them to be reduced in size when not in use or extended when needed. These devices typically handle material loads ranging from several tons to hundreds of tons per hour, and convey distances ranging from a few meters to tens of meters, making them suitable for operations of all sizes.

What are the types of portable belt conveyors?

Portable belt conveyors are widely used in a variety of applications due to their flexibility and maneuverability. Based on their functional and structural characteristics, common types include movable belt conveyors, hydraulic lift belt conveyors, and folding/telescopic belt conveyors. The following is a detailed introduction to these common types:

Portable Belt Conveyors

Portable belt conveyors are a common type of portable conveyor. They are typically equipped with wheels or tracks, allowing for easy movement between different work locations. This type of conveyor boasts a relatively simple structure and is easy to operate. It is widely used in locations requiring frequent relocation, such as ports, docks, storage yards, mines, and warehouses, primarily for loading, unloading, stacking, and transshipping bulk materials.

Hydraulic Lift Belt Conveyor

A hydraulic lift belt conveyor incorporates a mobile design with a hydraulic lift system. Using hydraulic cylinders, the conveyor's inclination angle and conveying height can be easily adjusted. This makes it particularly suitable for conveying materials to varying heights, such as loading materials into trucks, containers, or silos of varying heights, or for high stacking operations. Its flexible height adjustment significantly improves operational efficiency.

Folding/Telescopic Belt Conveyor

Folding/Telescopic Belt Conveyors are designed to address space constraints or long-distance conveying needs. Folding belt conveyors fold up when not in use, significantly reducing their footprint and facilitating storage and transportation. Telescopic belt conveyors, on the other hand, utilize a telescopic mechanism to freely adjust the conveyor belt length, enabling both short-distance conveying and extended reach when needed. This type of conveyor is very practical in logistics sorting centers, warehouses, and loading and unloading operations, effectively utilizing limited space and improving loading and unloading efficiency.

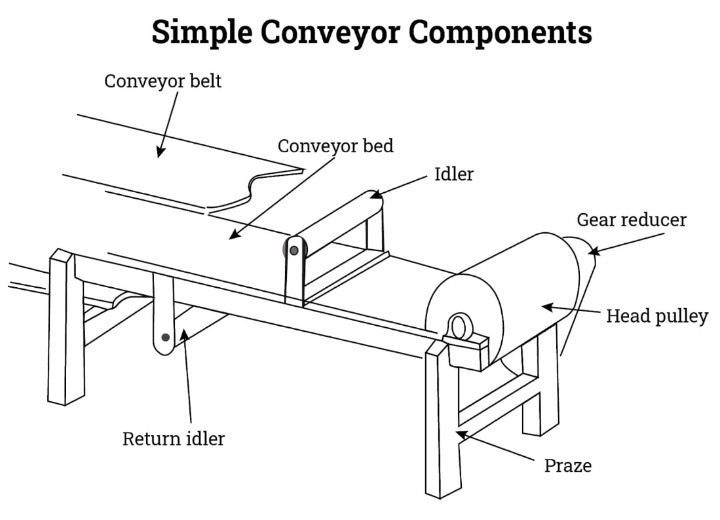

What is the structure of a portable belt conveyor?

A portable belt conveyor is compact and primarily consists of a conveyor belt, a wheeled or tracked frame, a motor drive, load and return rollers, and an adjustable height adjustment and tensioning device to ensure flexible and stable material transport. It typically consists of the following core components:

The conveyor belt: This is the primary component for carrying and conveying materials. It is commonly made of materials such as rubber, PVC, and PU to accommodate different materials and environments. The belt surface can be designed to be smooth, patterned, or with baffles or skirts to prevent material from sliding or spilling.

The frame: This is the backbone of the conveyor, supporting all components. The frame of a portable conveyor is typically made of lightweight, high-strength steel or aluminum alloy to ensure strength and ease of movement. The frame is designed with wheels or tracks for easy movement.

The drive unit: This provides power to the conveyor and typically consists of a motor, a speed reducer, and a drive roller. The motor drives the drive roller through the speed reducer, and the friction between the drive roller and the conveyor belt creates a circular motion for the conveyor belt. Load and return rollers: Load rollers are located above the conveyor belt, supporting the portion of the belt carrying material and preventing it from sagging. Return rollers are located below the conveyor belt, supporting the unloaded return portion. These rollers ensure smooth and stable conveyor belt operation.

Height adjustment device: This is a key feature of portable conveyors. Depending on the type, it may be a simple manual winch or a hydraulic lift system. This device allows the user to adjust the conveyor's inclination angle and conveying height to accommodate various loading and unloading requirements, such as loading materials into trucks or silos at different heights.

Tensioning device: The tensioning device adjusts the tension of the conveyor belt. A belt that is too loose can easily slip, affecting conveying efficiency; a belt that is too tight can increase belt wear. The tensioning device ensures the conveyor belt maintains proper tension during operation by adjusting the position of the tail roller.

What are the advantages of portable belt conveyors?

The mobility and flexibility of portable belt conveyors allow them to quickly adapt to different operating environments, significantly saving labor costs and improving work efficiency. Its excellent environmental adaptability and easy operation and maintenance make it an ideal choice for material handling and transfer. Here are its key advantages:

Mobility and flexibility: These are its core advantages. Portable belt conveyors are typically equipped with wheels or tracks, allowing for easy movement between different work areas without complex setup and disassembly. This flexibility enables them to quickly respond to changing operational needs and is particularly suitable for environments with frequent changes in work locations, such as ports, construction sites, farms, and warehouses.

Reduced labor costs and improved work efficiency: Through mechanized conveying, portable belt conveyors can significantly reduce the workload of manual handling, thereby reducing labor intensity and saving labor costs. Furthermore, their continuous conveying characteristics increase the speed of material loading, unloading, stacking, and transfer, improving overall work efficiency.

Excellent environmental adaptability: Many portable belt conveyors are designed with an adjustable hydraulic lift system, making them easily adaptable to various loading and unloading operations, such as loading materials into trucks or silos at different heights. Furthermore, their compact design and small footprint allow them to operate flexibly even in narrow or crowded spaces. Easy to operate and maintain: Compared to large, fixed conveyor systems, portable belt conveyors have a relatively simple structure and intuitive user interface, allowing most workers to operate them with minimal training. Furthermore, their parts are easily replaceable and maintainable, reducing future operating costs.

What are the applications of portable belt conveyors?

Portable belt conveyors provide a flexible and easy-to-deploy material handling solution. In loading and unloading operations, portable belt conveyors are a powerful tool for improving efficiency. Whether unloading bulk materials such as sand, gravel, and grain from trucks or loading packaged goods such as boxes and bagged products into containers, they can easily achieve continuous and rapid material transfer by adjusting the inclination angle and conveying height. Portable belt conveyors also demonstrate their powerful capabilities in stacking and transshipping. When materials need to be piled to a specific height, portable conveyors equipped with hydraulic lifting systems can easily adjust the discharge height for precise stacking, preventing material spillage and uneven stacking. Portable belt conveyors are also widely used in temporary or periodic operations such as construction sites, farms, and emergency response. For example, at construction sites, portable belt conveyors can be used to transport construction waste such as soil and gravel, or to deliver building materials such as concrete and sand to designated locations. On farms, they can be used for loading, unloading, sorting, and stacking grain. In emergency situations, they can be quickly deployed to clear debris and transfer supplies. In short, the application of portable belt conveyors is not limited to a specific industry. Their mobility, flexibility, and efficiency make them a versatile material handling tool, adaptable to changing work environments and providing reliable and economical solutions for a variety of loading, unloading, stacking, and transfer tasks.

Portable belt conveyors offer a different type of material handling method from fixed conveyor systems, adapting to the temporary or uncertain nature of work locations. Whether loading and unloading materials or transferring short distances within a site, this type of equipment can be deployed to suit the actual site layout. When selecting the right type and specification of equipment, factors such as the physical properties of the material, the total amount of material in a single operation, and the desired conveying path are often used to determine the appropriate equipment type and specifications.