Small Portable Belt Conveyor

Small portable belt conveyor is a lightweight and movable material conveying equipment, which is widely used in logistics, warehousing, express sorting, food processing, packaging and other industries. It is especially suitable for short-distance and light-load scenarios that require flexible handling or limited space.

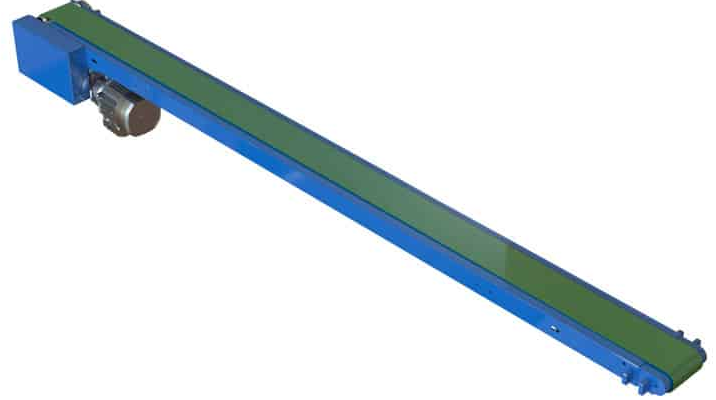

What is a small portable belt conveyor

Small portable belt conveyors are light and flexible, suitable for short-distance material transportation, and are widely used in warehouses, construction sites, farms and other scenarios. The equipment uses PVC or rubber conveyor belts, and the frame is mostly stainless steel, which is durable and easy to maintain. Width 100-500mm, conveying speed 0.8-1.6m/s, support height adjustment, suitable for bulk or small materials (such as grain, sand and gravel). Conveying capacity 50-200kg/h, material temperature <60℃. Some models are equipped with screening function, and the screening mesh can reach 20-100 mesh, which is suitable for powder material classification.

Classification of small portable belt conveyors

|

Type |

Picture |

Features |

Applicable scenarios |

Main parameters |

Screening mesh |

|

Mobile belt conveyor |

|

Equipped with mobile wheels, strong mobility, horizontal or inclined conveying |

Warehouses, docks, construction sites |

Width:100-500mm Speed:0.8-1.6m/s Conveying capacity: 50-300kg/h |

0-80 mesh |

|

Folding belt conveyor |

|

Foldable, space-saving, easy to carry |

Small processing plants, temporary work sites |

Width:150-400mm Speed:0.5-1.2m/s Conveying capacity: 30-150kg/h |

Screening mesh: 30-100 mesh |

|

Micro belt conveyor |

|

Small size, suitable for precision materials, desktop operation |

Laboratory, small production line |

Width:50-200mm Speed:0.3-1.0m/s Conveying capacity: 10-50kg/h |

Screening mesh: 50-120 mesh |

|

Multifunctional combined conveyor |

|

Can be combined and spliced, with screening or sorting function |

Food processing, chemical industry, mining |

Width:200-500mm Speed:0.8-2.0m/s Conveying capacity: 100-500kg/h |

Screening mesh: 20-100 mesh |

What is the working principle of a small portable belt conveyor?

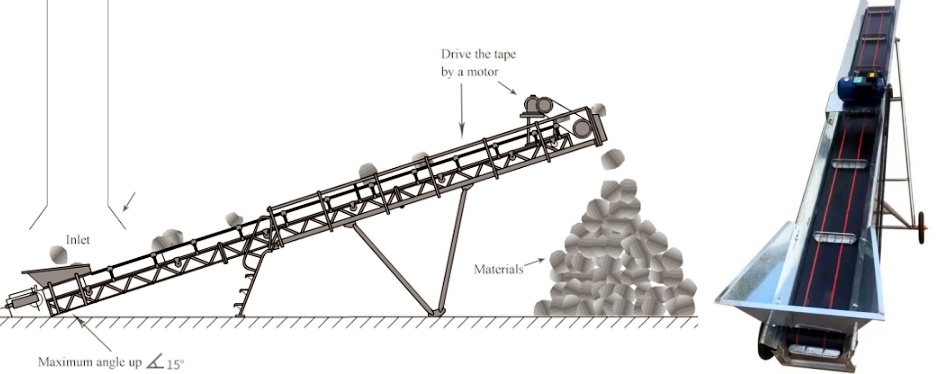

The small portable belt conveyor mainly relies on the motor (or battery) as the power source. The motor drives the drive roller (active roller) to rotate, and the friction force makes the conveyor belt (belt) move continuously. After the material is placed on the conveyor belt, it is smoothly transported from the loading end to the unloading end as the conveyor belt moves, realizing the transportation and transfer of materials.

Applicable materials for small portable belt conveyors

Small portable belt conveyors are designed to meet the different needs of bulk material handling systems. They are mainly used for bulk material storage, bulk material transfer, and ship loading and unloading. Our portable conveyors can handle the following materials:

River sand, artificial sand, aggregate, gravel, crushed stone, etc.

Iron ore, copper ore, silver ore, manganese ore, bauxite, alumina ore, etc.

Coal, limestone, basalt, granite, feldspar, etc.

Slag, tailings, construction waste, soil slurry, etc.

Wood chips, sawdust, fertilizer, etc.

Video of small portable belt conveyor

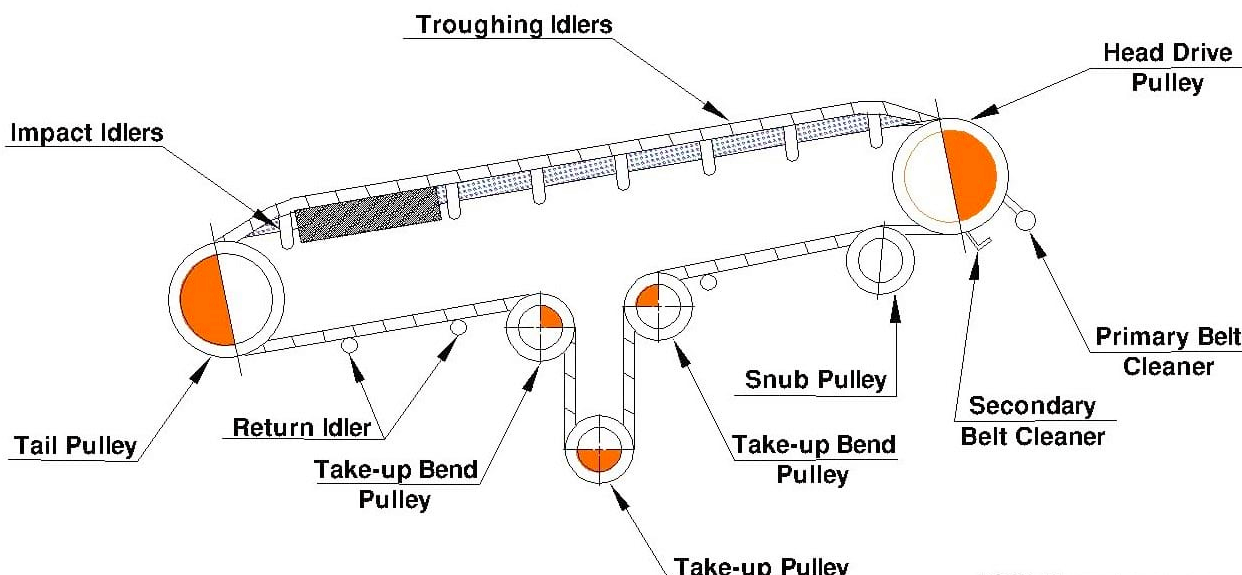

Basic structural components of small portable belt conveyors

Drive device: Provides power, commonly an electric motor.

Conveyor belt: Mainly carries materials, mostly made of rubber, PVC or PU.

Support structure: Supports the entire conveyor frame, usually made of steel or aluminum alloy.

Roller (roller): Responsible for driving the conveyor belt to move (active roller, redirecting roller).

Tensioning device: Maintain the tension of the conveyor belt to prevent slipping.

Mobile wheel (optional): Facilitates the movement of the whole machine, usually with a brake function.

Advantages of small portable belt conveyors

Multifunctional adaptability: Supports height and angle adjustment (tilt angle up to 30°), adjustable conveyor belt width (50-500mm) and speed (0.3-2.0m/s), suitable for bulk materials (such as grain, sand and gravel) or small items, some models have integrated screening function (mesh size 20-120 mesh).

Lightweight design: The body is made of lightweight aluminum alloy or carbon steel, the weight of the whole machine is only 20-100kg, and one person can push or fold it for transportation. After folding, the volume is reduced by more than 50% (for example, the length of the 8-meter model after folding is ≤3 meters), which can be put into a truck, tricycle or warehouse corner to save storage space.

Freedom of movement: The bottom universal wheel is equipped with a brake design, which can move quickly on a variety of ground such as cement floor, gravel road, etc., with a small turning radius, suitable for narrow spaces (such as workshop aisles, containers) Operation.

High adaptability and customization: It can be customized according to different conveying materials, distances, heights, etc., such as replacing belts of different materials and patterns, adjusting conveying speeds, adding side baffles, etc.

Technical parameters of small portable belt conveyors

|

Model |

DH5051 |

DH5071 |

DH50101 |

DH50102 |

DH50102A |

DH50151 |

DH50152 |

DH50152A |

|||||||||

|

Conveyor length(m) |

5 |

7 |

10 |

10 |

10 |

15 |

15 |

15 |

|||||||||

|

Belt width(mm) |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

|||||||||

|

Belt speed(m/s) |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

|||||||||

|

Max. conveying |

1.63 |

1.59 |

1.77 |

4.52 |

4.52 |

1.61 |

6.32 |

6.32 |

|||||||||

|

Conveying |

M3/h |

160 |

160 |

160 |

125 |

125 |

160 |

125 |

125 |

||||||||

|

capacity |

t/h |

145 |

145 |

145 |

112 |

112 |

145 |

112 |

112 |

||||||||

|

Angle |

13°59' |

9°16' |

6.5° |

10°~22° |

10°~22° |

3.81° |

10°~22° |

10°~22° |

|||||||||

|

Model |

DY1.4 |

DY1.4 |

DY1.4 |

DY1.5 |

DY1.3 |

DY1.4 |

DY1.6 |

DY1.3 |

|||||||||

|

Drive pulley |

Power |

2.2 |

2.2 |

2.2 |

3.0 |

1.1 |

2.2 |

4.0 |

1.1 |

||||||||

|

KW |

|||||||||||||||||

|

Weight(Kg) |

518 |

604 |

892 |

1126 |

1071 |

1225 |

1491 |

1491 |

|||||||||

Applications of small portable belt conveyors

Small portable belt conveyor systems are ideal for transporting loose materials, debris, rocks, soil, cement, etc., and can be widely used in:

Underground/basement and crawl space excavation, mining

Tunnels, construction and demolition, disaster/rescue and recovery

Landscaping, greenhouses, sand and dirt removal

Swimming pool installation, firewood conveyors, tight channel operations

Difficult terrain work