Grain conveyor belt

Grain conveyor belts are industrial equipment specially used to convey grains (such as wheat, corn, rice and other crops) or other bulk materials. They are widely used in agriculture, grain processing, warehousing and logistics industries.

Product Description

Grain conveyor belts are designed to efficiently and smoothly transport a variety of grains such as wheat, corn, rice, soybeans and barley. It consists of a continuous belt made of materials such as rubber, PVC or special food-grade fabrics, moving over a series of pulleys and supported by idler rollers. Grain is loaded onto the belt from one point and unloaded from another, allowing large quantities of grain to be transported quickly and with minimal damage to the grain.

What are the types of grain conveyor belts?

|

Types |

Picture |

Description |

Applicable scenarios |

Advantages |

|

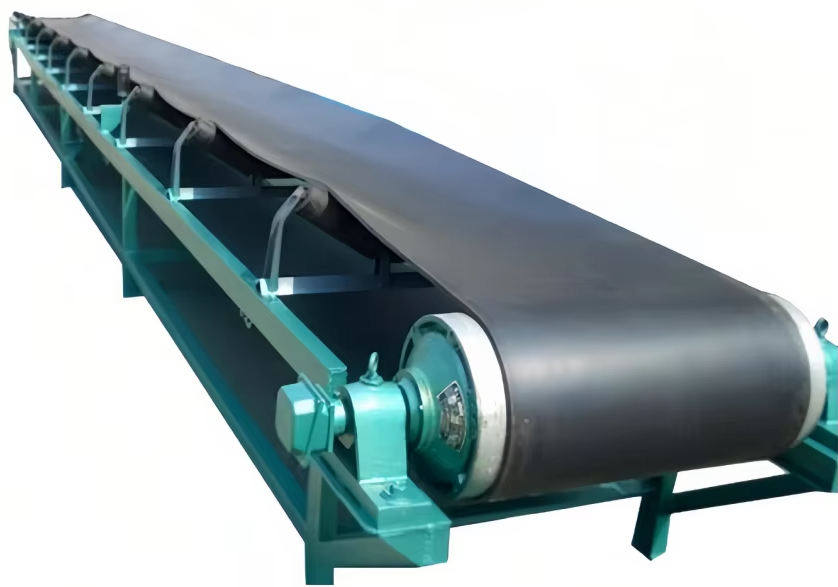

Belt conveyor |

|

Use flat belts made of rubber, PVC or PU to convey grain horizontally or at a small angle |

Grain silos, processing plants, short-distance transportation |

Low cost, smooth transportation |

|

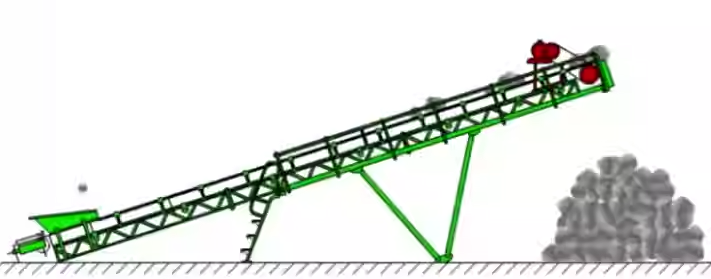

Large-angle belt conveyor |

|

Conveyor belts with baffles or wavy edges can achieve 30°-90°large-angle transportation |

Vertical lifting, places with limited space |

Space saving, suitable for height difference transportation |

|

Chain conveyor |

|

Use metal or plastic chain plates, suitable for heavy or high-temperature grain |

Heavy grain transportation, feed mills |

Durable Used, suitable for high temperature or heavy load |

|

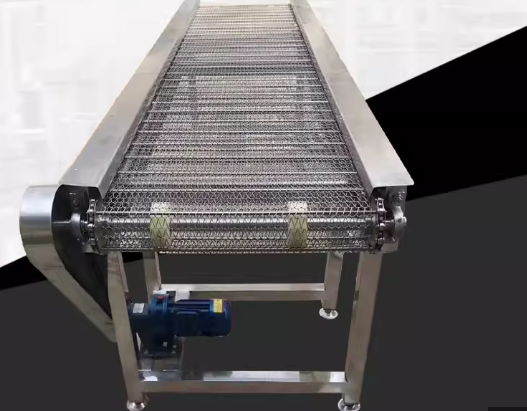

Mesh belt conveyor |

|

Mesh structure conveyor belt, suitable for ventilation, cleaning or light grains |

Food processing, grain cleaning or drying |

Good ventilation, easy to clean, in line with food grade requirements |

|

Bucket elevator |

|

Use bucket fixed on belt or chain, vertical or nearly vertical grain transportation |

Grain depot, processing plant height difference transportation |

Vertical transportation has high efficiency and small footprint |

|

Screw conveyor |

|

Propels grains by rotating spiral blades, suitable for short-distance horizontal or small angle transportation |

Grain silo unloading, processing plant internal transportation |

Compact structure, suitable for closed transportation |

How does a grain conveyor belt work?

Grain conveyor belt is a kind of conveying equipment commonly used in agriculture and grain processing, mainly used to transport grains such as wheat, corn, rice, etc. from one location to another.

Feeding: Grains are evenly loaded onto the surface of the conveyor belt through a feed hopper or mechanical means.

Conveying: The motor drives the roller to rotate, driving the conveyor belt to run continuously along a fixed track (horizontal, inclined or vertical), and the grain moves with the belt.

Unloading: After the grain reaches the end point, it is unloaded from the conveyor belt by gravity, scraper or unloading device and enters the next process or storage device.

Video of grain conveyor belt

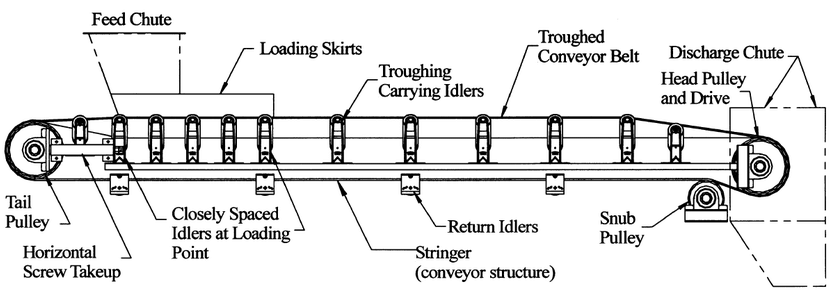

Structure of grain conveyor belt

The working principle of the grain conveyor belt is to drive the continuous circulation conveyor belt through a mechanical transmission system to transport grain from the starting point to the end point. The grain conveyor belt consists of a conveyor belt (made of materials such as rubber, PVC, PU or metal mesh), a drive device (motor, reducer and drive roller), a support structure (roller, frame), and an auxiliary device (feed hopper, unloading device, protective cover).

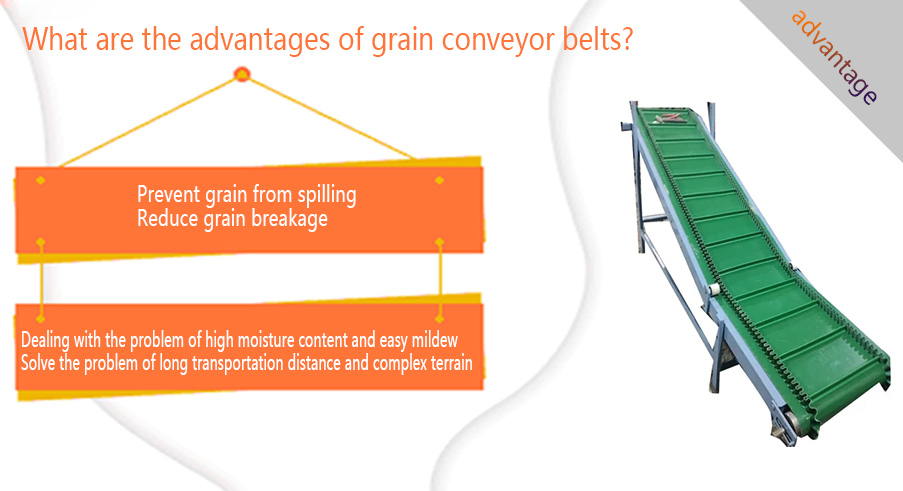

What are the advantages of grain conveyor belts?

Prevent grain from spilling: Use a skirt-belt grain conveyor belt. The skirts on both sides can effectively prevent grain from falling from the edge of the conveyor belt during transportation, further improving the grain blocking ability. It is suitable for conveying at large angles or conveying grains that are easy to scatter.

Reduce grain breakage: Reasonably select the running speed of the conveyor belt. For grains that are easy to break, such as corn and rice, a lower belt speed will be used, usually around 1.0-1.5m/s, to reduce the collision and friction of grains during transportation.

Dealing with the problem of high moisture content and easy mildew: In humid seasons or rainy days, it is easy to get damp and mildew during transportation. You can use waterproof grain conveyor belt materials or stainless steel structures to prevent rust, control the transportation time, and transfer and store in time.

Solve the problem of long transportation distance and complex terrain: Farms, ports and other places have complex terrain and need to flexibly layout the transportation system. You can choose mobile conveyor belts or telescopic conveyors, use multi-stage conveying design, and combine horizontal and inclined.

What are the applications of grain conveyor belts?

Grain conveyor belts are indispensable mechanical equipment in the grain industry. They are used throughout the entire process from field to storage and are widely used in agriculture, grain processing, storage, logistics and food industries for efficient and continuous transportation of grains (such as wheat, corn, soybeans, rice, etc.) or other bulk materials.

Related parameters of grain conveyor belt

|

Project |

Parameters/Description |

Project |

Parameters/Description |

|

Conveyor belt type |

Flat belt, PVC belt, rubber belt, canvas belt, etc. |

Conveying speed |

0.5~2.5m/s |

|

Belt width |

Common 300mm, 500mm, 650mm, 800mm, 1000mm, etc. |

Conveying direction |

One-way or two-way |

|

Conveying length |

Customized according to needs, common 5m~30m |

Dustproof/enclosed structure |

Optional closed cover or open structure |

|

Conveying capacity (output) |

5~200 tons/hour, depending on bandwidth, speed and material density |

Control system |

Manual, electric control box, PLC automatic control, etc. |

|

Frame material |

Carbon steel spray paint, stainless steel, galvanized steel, etc. |

Tensioning device |

Screw type, heavy hammer type, automatic tensioning, etc. |

|

Noise level |

≤75dB |

Motor power |

1.5~15kW |

|

Conveying angle |

0°~ 30°, with anti-slip baffle up to 45° |

Applicable grains |

wheat, corn, rice, soybean, rapeseed, etc. |

Customer Cases of Grain Conveyor Belts

|

|

|

|

|

|

Farm grain transfer |

Feed plant material handling |

Railway or Truck Loading Systems |

Grain processing plants |

|

Used to quickly transport harvested grain to transport vehicles or temporary grain storage points in the fields |

Transport raw materials such as corn, soybean meal, and wheat bran to batching, crushing, and mixing equipment |

Used to convey grain to train or truck compartments for rapid shipment |

Continuously transport grain from different processes such as cleaning, shelling, drying, and screening |

|

|

|

|

|

|

Biomass energy plant |

Port/terminal unloading |

Grain storage loading and unloading operations |

Dood processing and grading system |

|

Convey grains or husks as biomass raw materials into power generation or compression molding equipment |

After the grain is shipped to the port by ship, it is unloaded and transferred to the grain storage silo using conveyor belts |

At national or local grain reserves, grain is transported to warehouses or loaded from warehouses |

Convey foods into grading and screening machines, impurity removal equipment, etc. to ensure seed quality. |

Grain Conveyor Belts Manufacturer

Dahan Machinery Co., Ltd. is a manufacturer specializing in the production of grain conveyor belts and related material conveying equipment. It focuses on the design, research and development, production and sales of vibrating screens, conveyors, elevators and other equipment. Its products are widely used in agriculture, grain processing, warehousing and logistics and other fields.