Yellow Corn Inclined Belt Conveyor

Yellow corn inclined belt conveyor is an inclined belt conveyor specially designed for conveying yellow corn (such as Tongliao yellow corn, pearl glutinous corn and other varieties). Its core function is to realize the vertical or slope transportation of corn grains through the inclination angle. It is widely used in agricultural warehousing, food processing, feed production and other scenes.

What is Yellow Corn Inclined Belt Conveyor?

Yellow Corn Inclined Belt Conveyor is a portable belt conveyor with an inclined structure specially used for efficient and stable transportation of grain crops such as yellow corn grains. It is widely used in the agricultural field, such as grain warehousing, loading, dryer feeding, temporary stacking and transportation, etc. It is particularly suitable for use in working environments with limited terrain or requiring a certain height of transportation. Mechanical equipment that uses electric belt drive and combines agricultural material characteristics (such as particle size, humidity, and fluidity) to transport granular materials such as yellow corn from low places (such as the ground or warehouse) to high places (such as storage silos, processing equipment, or transport vehicles). It is equipped with an adjustable angle tilting structure, usually with anti-slip design, sealing structure, corrugated sidewalls or skirts, which solves the problems of spillage, breakage, and hygiene of granular materials during inclined transportation.

Types of yellow corn inclined belt conveyors

Yellow corn inclined belt conveyors can be divided into the following types according to belt design, frame, and mobility. Each type is designed for specific needs of corn transportation (such as anti-slip, baffle, pattern, etc.).

1. Based on belt design:

|

Type |

Image |

Belt features |

Applicable tilt angle |

Typical application |

|

Smooth belt inclined conveyor |

|

Smooth belt surface, no special structure |

Small |

Conveying dry, fluid yellow corn with high friction coefficient, small tilt angle |

|

Baffle inclined conveyor |

|

The belt surface has fixed-spaced baffles (or partitions) to prevent corn particles from sliding off during inclined conveying |

Large |

Conveying yellow corn with a large tilt angle, especially suitable for small particles with good fluidity. |

|

Herringbone or patterned belt inclined conveyor |

|

The belt surface has raised herringbone, V-shaped or other patterns to increase friction with corn particles and prevent sliding |

Medium |

Conveying yellow corn with a certain tilt angle, suitable for occasions requiring a certain gripping force |

|

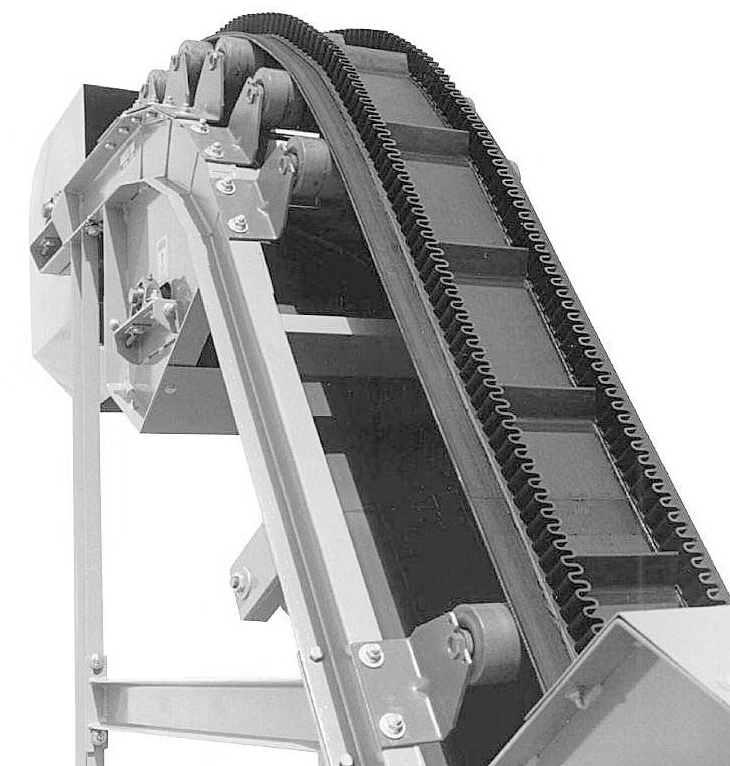

Sidewall belt inclined conveyor |

|

The belt has wavy or vertical skirts (side walls) on both sides, which can effectively constrain yellow corn and achieve large tilt angle conveying |

Very large |

Conveying yellow corn with a very large tilt angle can significantly save space and is suitable for occasions with high lifting heights |

2. Based on the framework and mobility:

Fixed inclined belt conveyor: These conveyors are fixed in one location and are usually part of a larger permanent processing or handling system.

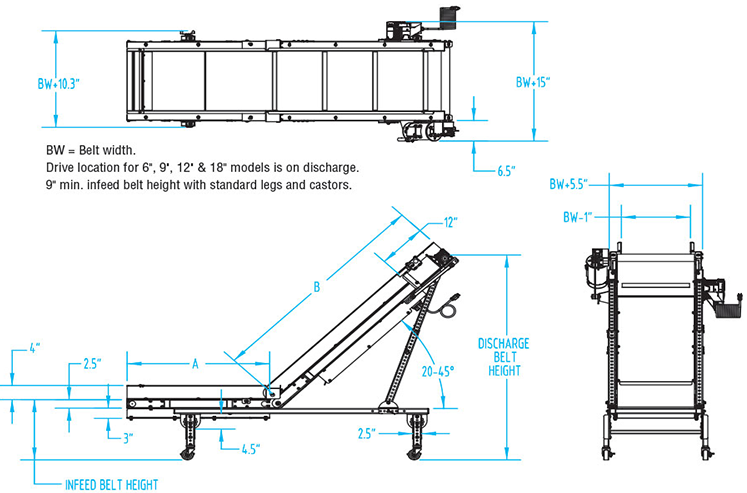

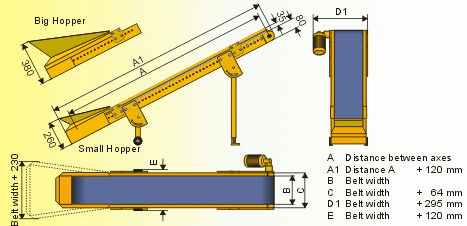

Portable or mobile inclined belt conveyor: These conveyors are equipped with wheels or slides to facilitate movement between different locations. They are often used to load and unload trucks or rail vehicles in different areas. Some conveyors have adjustable inclination angles.

What is the function of the yellow corn inclined belt conveyor?

Lifting and conveying: This is its most core function. Through the inclined belt movement, the yellow corn is conveyed upward against gravity to achieve material transfer between different heights.

Quantitative conveying: By controlling the running speed of the belt, a certain degree of quantitative conveying can be achieved, and a predetermined amount of yellow corn can be conveyed to the target location.

Continuous conveying: As long as the feed is sufficient, the inclined belt conveyor can achieve continuous yellow corn conveying and improve material handling efficiency.

Reduce material damage: Compared with some mechanical lifting equipment, the yellow corn inclined belt conveyor has less impact and friction, and can convey yellow corn more gently and reduce the breakage rate.

Video of Yellow Corn Inclined Belt Conveyor

What is the working principle of the Yellow Corn Inclined Belt Conveyor?

The working principle of the Yellow Corn Inclined Belt Conveyor mainly relies on the combination of friction and mechanical movement, as well as physical constraints that may be added according to different designs.

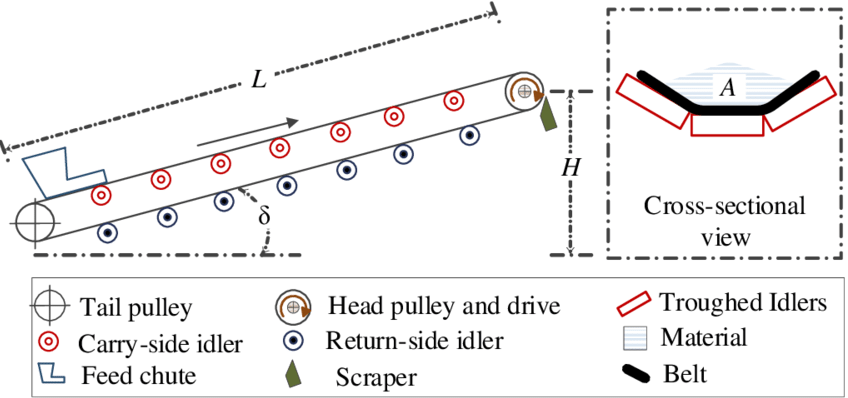

①The motor drives the reducer, and the reducer drives the active roller (driving roller) to rotate.

②When the active roller rotates, the friction drives the conveyor belt to move in the predetermined direction. The conveyor belt forms a closed conveying loop around the active roller and the driven roller (redirecting roller).

③Yellow corn is usually evenly loaded onto the moving conveyor belt through a hopper or other feeding device at the lower end of the conveyor. The conveyor belt carrying yellow corn runs upward at a certain inclination angle driven by the motor.

④When the conveyor belt runs to the top, the yellow corn will be unloaded due to gravity or guided by a scraper or other device at the discharge roller, and enter the subsequent processing link or storage bin.

Structure of yellow corn inclined belt conveyor

Belt body: mostly made of anti-slip rubber belt or PVC skirt belt, suitable for conveying corn particles

Drive motor: provides stable conveying power, often equipped with variable frequency speed regulation function to control flow

Bracket and angle adjustment device: adjustable conveying angle to meet different unloading height requirements

Mobile wheel set: with universal wheels or pneumatic wheels, easy to move between farmlands or warehouses

Funnel/receiving hopper: used for receiving harvesters, granary ports or drying equipment feeding ports

Technical specifications of yellow corn inclined belt conveyor

|

Width(mm) |

Conveying length (m) Power (kw) |

Conveying speed(m/s) |

Conveying volume(t/h) |

||||

|

400 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

30-60 |

||

|

3 |

3-4 |

4-7.5 |

|||||

|

500 |

≤10 |

12-15 |

15-30 |

40-80 |

|||

|

3 |

4-5.5 |

5.5-7.5 |

|||||

|

650 |

≤10 |

12-15 |

15-30 |

80-120 |

|||

|

4 |

7.5 |

7.5-11 |

|||||

|

800 |

≤10 |

12-15 |

15-30 |

120-200 |

|||

|

4 |

7.5 |

7.5-15 |

|||||

|

1000 |

≤10 |

10-20 |

20-40 |

200-320 |

|||

|

5.5 |

7.5-11 |

11-22 |

|||||

|

1200 |

≤10 |

10-20 |

20-40 |

290-480 |

|||

|

7.5 |

7.5-15 |

15-30 |

|||||

|

1400 |

≤10 |

10-20 |

20-40 |

400-680 |

|||

|

11 |

15-22 |

22-45 |

|||||

|

1600 |

≤10 |

10-20 |

20-50 |

600-1080 |

|||

|

15 |

22-30 |

30-75 |

|||||

|

1800 |

≤10 |

10-20 |

20-50 |

1.0-2.0 |

800-1500 |

||

|

18.5 |

30-45 |

45-110 |

|||||

|

2000 |

≤10 |

10-20 |

20-50 |

1000-2000 |

|||

|

22 |

45-55 |

55-132 |

|||||

|

2400 |

≤10 |

10-20 |

20-50 |

1500-3000 |

|||

|

30 |

55-75 |

75-185 |

|||||

Application of yellow corn inclined belt conveyor

Yellow corn inclined belt conveyor has a wide range of applications in agriculture, grain processing and warehousing. Its core lies in efficiently and stably lifting yellow corn to the required height to serve subsequent processing or storage links.

Agricultural harvesting and primary processing: After small farms or cooperatives collect the harvested yellow corn, they may need to transport it to the primary drying or threshing plant. Using a fixed yellow corn inclined belt conveyor, corn can be lifted from the ground hopper or the outlet of a simple elevator to the feed port of the dryer or the secondary conveyor belt of the thresher to achieve automated connection of the process.

Grain storage and transportation: When large grain depots receive newly harvested yellow corn, they need to unload it from the transport vehicle and transport it to a high-altitude granary for storage. The high-angle yellow corn inclined belt conveyor can lift the corn to the feed port at the top of the granary at a large inclination angle, realizing efficient storage of corn in different bins.

Raw material transportation in feed mills: In feed production plants, yellow corn is one of the important raw materials. Fixed yellow corn inclined belt conveyors are widely used to lift yellow corn from the raw material silo to the feed port of processing equipment such as crushers and mixers. Depending on the different production line layouts and equipment heights, multi-stage inclined conveyors may be required for relay transportation.

Raw material transportation for deep processing of corn: In factories producing foods such as corn starch and corn oil, yellow corn needs to be pre-treated by washing and soaking before being transported to subsequent processing equipment. Food-grade yellow corn inclined belt conveyor, whose material meets hygiene standards, can lift the processed corn to the feed port of equipment such as reactors and pulpers.

Selection suggestions for yellow corn inclined belt conveyor

Choosing a suitable yellow corn inclined belt conveyor requires careful consideration of multiple factors to ensure that it can complete the transportation task efficiently, stably and safely.

1. Clarify the transportation requirements: transportation volume, transportation height and horizontal distance, inclination angle, transportation speed, working environment, whether it needs to be moved, etc.

2. Consider the characteristics of yellow corn: particle size and shape, fluidity, humidity, whether protection is needed, etc.

3. Choose the appropriate conveyor belt type:

Smooth belt inclined conveyor: Suitable for situations where the inclination angle is small and the yellow corn is dry and has good fluidity

Baffle inclined conveyor: Suitable for larger inclination angles. The height and spacing of the baffles need to be determined according to the size of the corn and the conveying volume

Herringbone or patterned belt inclined conveyor: suitable for medium inclination angles, the cost is between smooth belt and belt baffle

Sidewall belt inclined conveyor: can convey yellow corn at very large inclination angles, even close to vertical conveyance

4. Determine the structure and configuration of the conveyor

5. Considering economy and reliability

Scenario requirements Recommended configuration Technical parameter examples

Small grain silo (<50t/h) Belt width 500mm, inclination 25°, electric drive (3kW) Belt speed 1.5m/s, sidewall height 100mm

Medium-sized feed mill (100t/h) Belt width 800mm, corrugated sidewall + diaphragm, diesel drive (7.5kW) Belt speed 2.0m/s, equipped with cyclone dust collector

Port loading (200t/h) Belt width 1000mm, hydraulic lifting (adjustable height 0-10m) Rain cover + remote control system, IP65 protection level

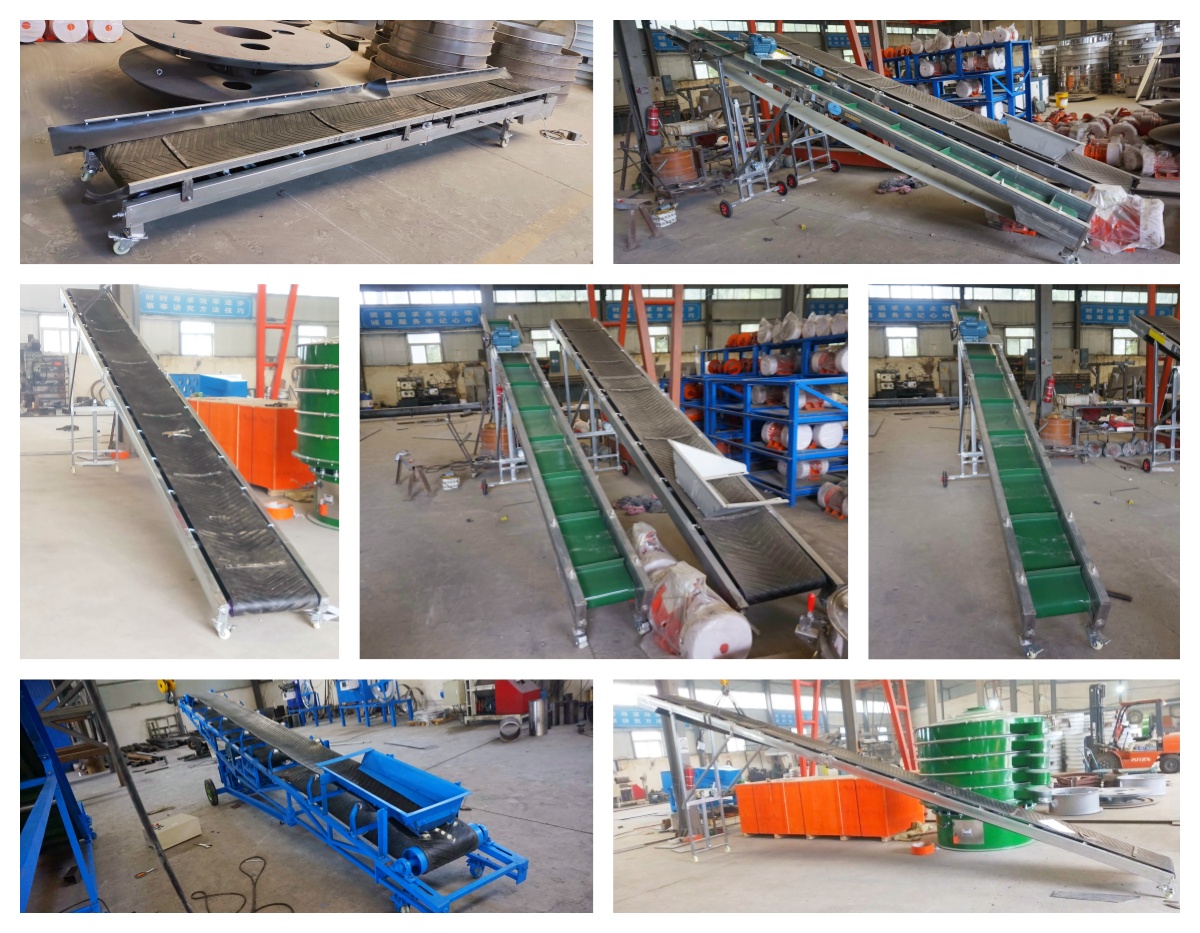

Yellow corn inclined belt conveyor manufacturer

Dahan Machinery is a manufacturer of vibrating screening equipment and conveying equipment. Our product line usually includes various types of belt conveyors.

If you want to know the specific information of the yellow corn inclined belt conveyor produced by Dahan Machinery, it is recommended that you contact us directly through customer service or email.

My whatsapp: +86 15236742901, e-mail: sale@xxdahan.com

Consult the sales or technical department by phone and explain your requirements in detail (such as conveying capacity, inclination angle, conveying height, belt material, whether there are special requirements, etc.) so that we can provide specific model recommendations and quotes. If you have any questions during the contact, we can also answer them for you.