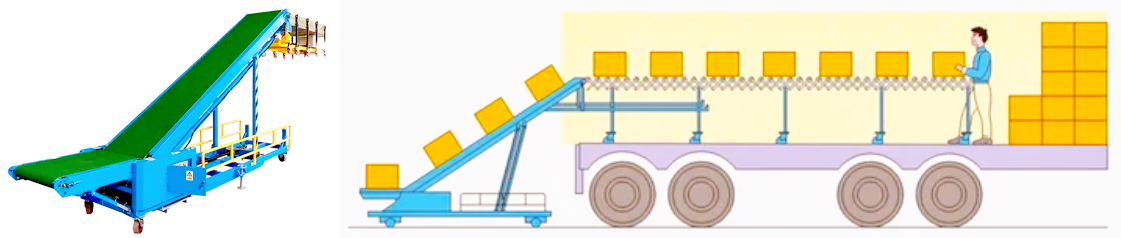

Truck loading conveyor is a device used to quickly load bulk goods (such as grains, powders, and granules) or packaged goods (such as boxes and bags) from the ground or production line into a truck's cargo hold. It can be fixed, mobile or telescopic, depending on actual needs. As a flexible material handling solution, it is mainly composed of a belt conveyor body, a mobile chassis, a lifting and adjusting device, a drive system, etc. It is suitable for loading and unloading operations of powder materials, granular materials, bagged materials, boxes, etc. The manufacturer meets customers' requirements for efficiency, convenience and work intensity under different working conditions through structural modular design and multiple functional configurations.

A truck loading conveyor is a device used to quickly load materials into trucks, containers, or truck beds. Based on its operating principle, power source, and method of movement, it can be categorized as hydraulic or non-hydraulic, mobile or fixed, and by motor and power configuration. The following describes these types in detail:

Hydraulic Truck Loading Conveyor

Technical Parameters: Lifting height and angle: Typically driven by a hydraulic cylinder, it allows for a wide range of lifting and lowering, with an adjustable maximum tilt angle to accommodate truck beds of varying heights. Regarding load capacity: The hydraulic system provides stable and powerful thrust, so this type of equipment typically has a higher load capacity. Operation: Equipped with a hydraulic control handle or button, it is relatively simple and labor-saving, allowing for smooth lifting and tilting.

Features: High stability. The hydraulic system provides smooth power output, resulting in low vibration and minimal impact on materials during lifting. High adjustability allows for precise control of lifting height and angle, adapting to a wide range of truck models and loading conditions. However, compared to non-hydraulic systems, hydraulic systems are more complex, resulting in higher maintenance and initial purchase costs.

Non-Hydraulic Truck Loading Conveyor

Technical Parameters: Lift height and angle are primarily adjusted through mechanical mechanisms (such as screws, gears, or pulleys), and the adjustable range is generally smaller than that of hydraulic systems. Load capacity relies on mechanical transmission, resulting in a relatively limited load capacity. Operation typically requires a manual rocker arm, handwheel, or simple electric lifting mechanism.

Features: Simple structure, easy-to-understand and maintain mechanical structure, and relatively low failure rate. Low cost, requiring no complex hydraulic system, resulting in lower manufacturing and maintenance costs. However, flexibility is limited, with a relatively limited range of height and angle adjustment, and operation may require more physical effort.

Mobile Truck Loading Conveyor

Technical Parameters: Mobile: Equipped with wheels or tracks, it can be easily moved to different work sites. The overall size and weight of the machine are compact, making it easy to transport and deploy. Regarding conveying length, some mobile conveyors are designed with telescopic features, allowing the conveying length to be adjusted as needed.

Features: Highly adaptable to various locations, suitable for use in scenarios where loading locations frequently change, such as logistics centers, port terminals, or large warehouses. Versatile: One unit can serve multiple loading and unloading areas. Easy installation, requiring no complex fixed foundation, allowing for immediate use.

Motor Configuration for Truck Loading Conveyor

Technical Parameters: Motor power: Motors of varying power are selected based on parameters such as conveying volume, conveying length, and inclination angle. Typically, the motor drives a reducer, which in turn drives the rollers via a chain or belt.

Features: Powerful: The motor provides stable and continuous power, enabling long periods of continuous operation. Easy to operate: Simply plug in the power cord for easy startup. However, it requires a stable power supply and is not suitable for use in off-site environments.

Truck Loading Conveyors Equipped with Generators or Batteries

Technical Parameters: Generator power/battery capacity. The power should match the conveyor's required power. The battery capacity should be selected based on operating time and charging convenience.

Features: Unrestricted by external power sources, it can operate in remote areas without electricity. Highly mobile, it is often used in conjunction with mobile conveyors, enhancing its flexibility in various environments. Operating costs: Compared to using direct mains electricity, generator or battery-powered systems have higher operating costs. Generators require regular refueling and maintenance, while batteries require regular charging.

The main operating principle of a truck loading conveyor is to transport materials from the ground to the interior of a truck or container using a continuously running spiral or belt conveyor. This involves using a continuous conveyor belt or roller to lift materials from a lower surface (such as the ground or warehouse platform) to a height that matches the truck bed, and then smoothly transporting the materials into the bed. The following is a detailed description of its operation:

Feed port: Materials enter the truck loading conveyor from a production line, warehouse or other source through a silo or conveyor belt.

Transmission: Materials move along the conveyor through the conveyor belt or spiral system of the truck loading conveyor.

Loading: The conveyor belt or spiral belt transports the materials to the loading area of the truck, and adjusts the angle or speed of the conveyor through the control system so that the materials are evenly and quickly loaded into the truck cargo hold.

The advantages of truck loading conveyors include their ability to address uneven loading by dynamically adjusting the unloading position, reducing the loss of fragile materials with a speed-controlled screw conveyor, preventing the accumulation of sticky materials with a U-shaped trough or shaftless design, and effectively controlling dust through an enclosed structure, all while achieving loading operations. The following are its key advantages:

Solve uneven loading

The inventory is concentrated on the truck, resulting in unbalanced loading weight or low space utilization. Truck loading conveyors can use telescopic belt pipe machines that can extend into the truck and dynamically adjust the unloading position to ensure uniform distribution.

Handle material loss or verification

Fragile inventory materials (such as grain) may deteriorate due to extrusion, or sensitive inventory (such as food raw materials) may deteriorate due to quality. The screw conveyor of the truck loading conveyor adjusts the speed (such as 20-50 RPM) to reduce mechanical damage to the unloading.

Prevent accumulation and poor flow

Sticky or wet terminals (such as wet grain, sticky powder) may block the pipeline channel and affect loading efficiency. Truck loading conveyors can use U-groove spiral pipe machines. Variable pitch screws or shaftless designs can be used to reduce unloading.

Avoid simultaneous flying and environmental pollution

Powdered inventory is prone to generate a lot of pollution during loading, polluting the environment and may cause health or safety hazards. The truck loading conveyor adopts a U-shaped trough spiral pipe machine, which can be equipped with a cover plate or a pipe structure to reduce overflow.

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

The application of truck loading conveyors is mainly concentrated in logistics, warehousing, agricultural product processing, building materials loading and unloading, grain storage, industrial production and other scenarios that require efficient manual replacement of loading and unloading operations. Its core function is to quickly, continuously and smoothly transport materials from the ground or production line to the inside of the truck compartment, or unload in the opposite direction, thereby greatly improving loading and unloading efficiency, reducing labor costs and reducing the labor intensity of workers.

Logistics warehousing: Truck loading conveyor is used to transport goods from the inside of the warehouse to the truck for distribution. Whether it is small goods or large goods, the truck loading conveyor can complete the loading task quickly and accurately.

Mining: Truck loading conveyor is used to load the mined ore, coal and other materials onto the transport truck, which can adapt to the harsh working conditions and achieve efficient and stable material loading.

Construction: Truck loading conveyor is used to load construction materials such as sand and gravel onto the truck and transport them to the construction site. The conveying position and angle can be flexibly adjusted according to the layout of the construction site and the material requirements to ensure the timely supply of materials.

Port terminal: Truck loading conveyor is used to load goods from the yard onto the truck for transportation to other places. Ports have a wide variety of goods and a large flow rate. Truck loading conveyor can quickly and efficiently complete the loading operation of goods and ensure the smooth operation of port logistics.

Truck loading conveyor play a key role in material handling and are used in a wide range of applications, including bulk material loading, lifting various bulk materials such as coal, sand, ore, grain, cement, and fertilizer from the ground, hoppers, or silos, and loading them into trucks, rail cars, or containers. Truck-loading conveyors are also used for handling packages, boxes, and bagged items in logistics, warehousing, and distribution. With its retractable body, the conveyor can reach deep into the truck bed, smoothly delivering goods to or removing them from the truck bed. For conveying materials across height differences, when materials need to be transferred from a lower surface (such as the warehouse floor or the end of a production line) to a higher surface (such as the truck bed or the bottom of a container), the Truck Loading Conveyor can accomplish this task by tilting. It effectively overcomes height differences and enables seamless material transfer, making it a valuable tool for connecting different work surfaces or equipment. Truck Loading Conveyors also have unique applications in applications requiring dust and contamination control or handling sticky materials. For example, screw conveyors with enclosed ducts or covers effectively control dust, protecting the environment and operator health. Shaftless screw conveyors, on the other hand, can handle sticky or tangled materials, avoiding blockages and ensuring a continuous loading process. In summary, Truck Loading Conveyors are primarily used in various applications requiring loading and unloading, overcoming height differences, optimizing spatial layout, and handling materials in challenging environments.

Truck loading conveyor provides efficient, flexible and safe material loading solutions in multiple industries. It improves loading efficiency and reduces manual labor through automated control systems and adjustable designs. It is an indispensable equipment for material transportation in modern logistics, construction, chemical and other industries. If you have specific material transportation needs or need a customized solution, please provide more information and I can help you further analyze and select.

A: A truck loading conveyor can load materials of various sizes, shapes, and packaging, including bulk materials, bagged items, and cartons.

A: The price of a truck loading conveyor varies depending on the model, features, brand, and customization requirements, ranging from $200 to $7,000.

A: Depending on the type of material being loaded, vehicle size, site space, and automation requirements, options include hydraulic lift, telescoping, mobile, tilting, and fully or semi-automatic features. Customization is also possible.