Conveyor belt for lumpy materials

Conveyor belt for lumpy materials is a continuous conveying equipment specially designed for transporting large, irregularly shaped materials (such as ore, coal, crushed stone, building materials, etc.), and is widely used in mining, metallurgy, building materials, ports, power and other industries.What is a conveyor belt for lumpy materials?

Conveyor belt for lumpy materials is an industrial conveying equipment specially designed for efficient and reliable transportation of large, irregular or high-density materials. It uses high-strength materials and impact-resistant structures to achieve safe and efficient transportation of large, high-density materials, and transports lumpy lumpy, granular or powdered materials from one location to another. The core of its design is to balance the carrying capacity and durability, while reducing the operation and maintenance costs, becoming an indispensable key equipment in the heavy industry. This equipment solves the problems of ordinary conveyor belts being easy to wear, tear and scatter when dealing with large lumps of materials, and is widely used in heavy industries such as mining, metallurgy, building materials, ports, etc.

Applicable materials for conveyor belt for lumpy materials

conveyor belts for lumpy materials are suitable for transporting large-sized, irregularly shaped solid materials. Their applicability mainly depends on the physical properties of the materials (such as particle size, density, hardness, humidity, abrasiveness) and conveying conditions.

Coarse lumpy materials: materials with particle sizes (usually >50mm) such as ore (iron ore, copper ore), scrap steel, concrete lumpys, etc.

Medium lumpy materials: materials with particle sizes (usually 20-100mm) such as coal, sand and gravel, fertilizer particles, etc.

Fine lumpy/granular materials: materials with particle sizes (usually <20mm) such as grains, chemical raw material particles, crushed stone chips, etc.

Types of conveyor belts for lumpy materials

|

Type name |

Picture |

Structural features |

Applicable scenarios |

Core advantages |

|

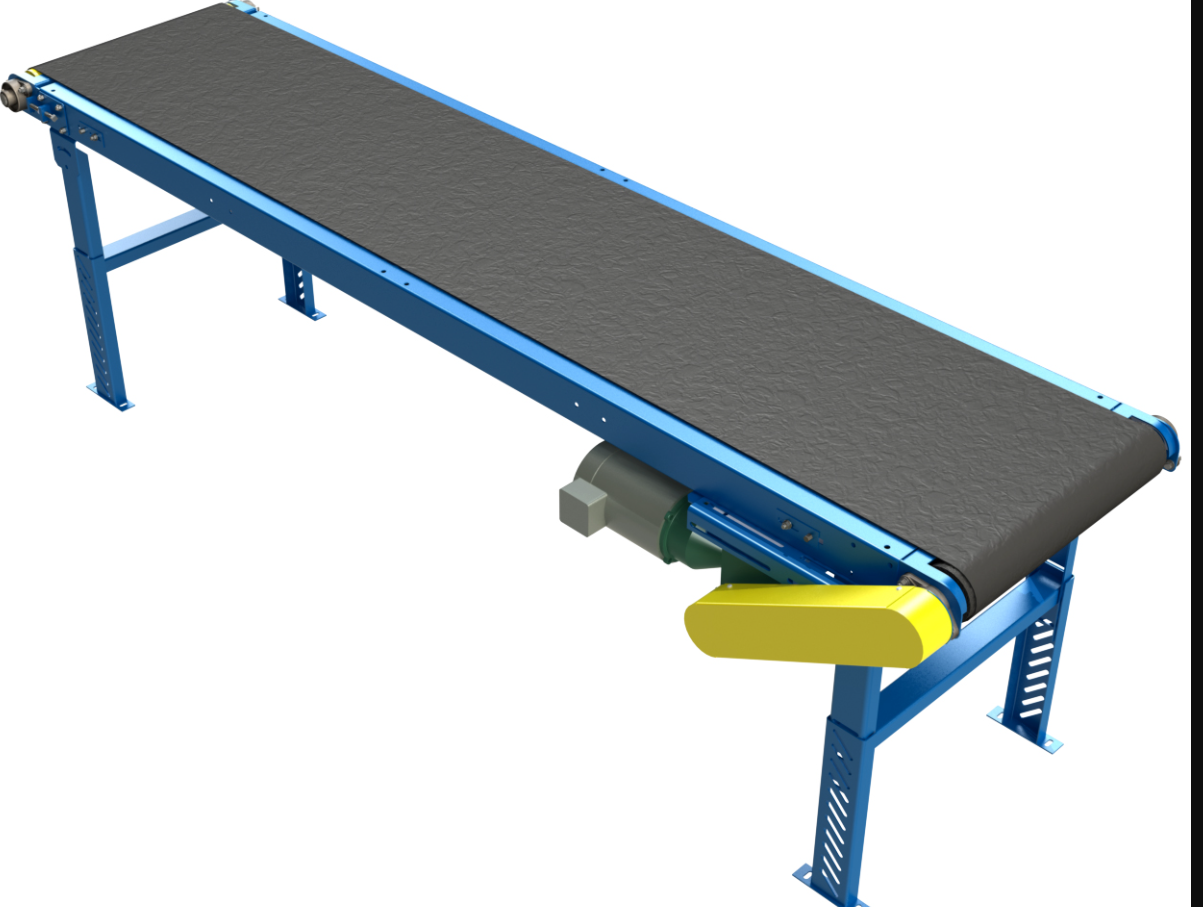

Flat conveyor belt |

|

Flat rubber/PVC belt body, no special sidewalls or partitions |

Horizontal or small inclination (≤15°) material transportation |

Suitable for short-distance, regular lumpy material transportation |

|

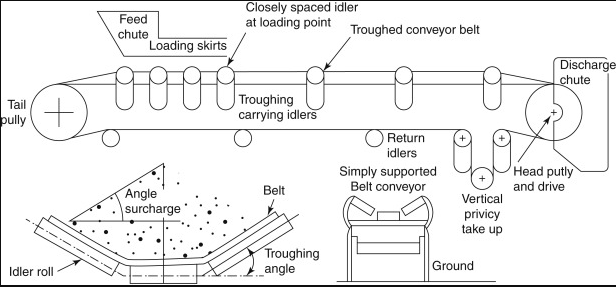

Trough conveyor belt |

|

Grooves are formed by roller groups (usually 35°~45°), and transverse bars can be added to the belt body |

Medium-distance transportation of lumpy materials (such as ore and coal) |

Prevent material side leakage, adapt to medium inclination |

|

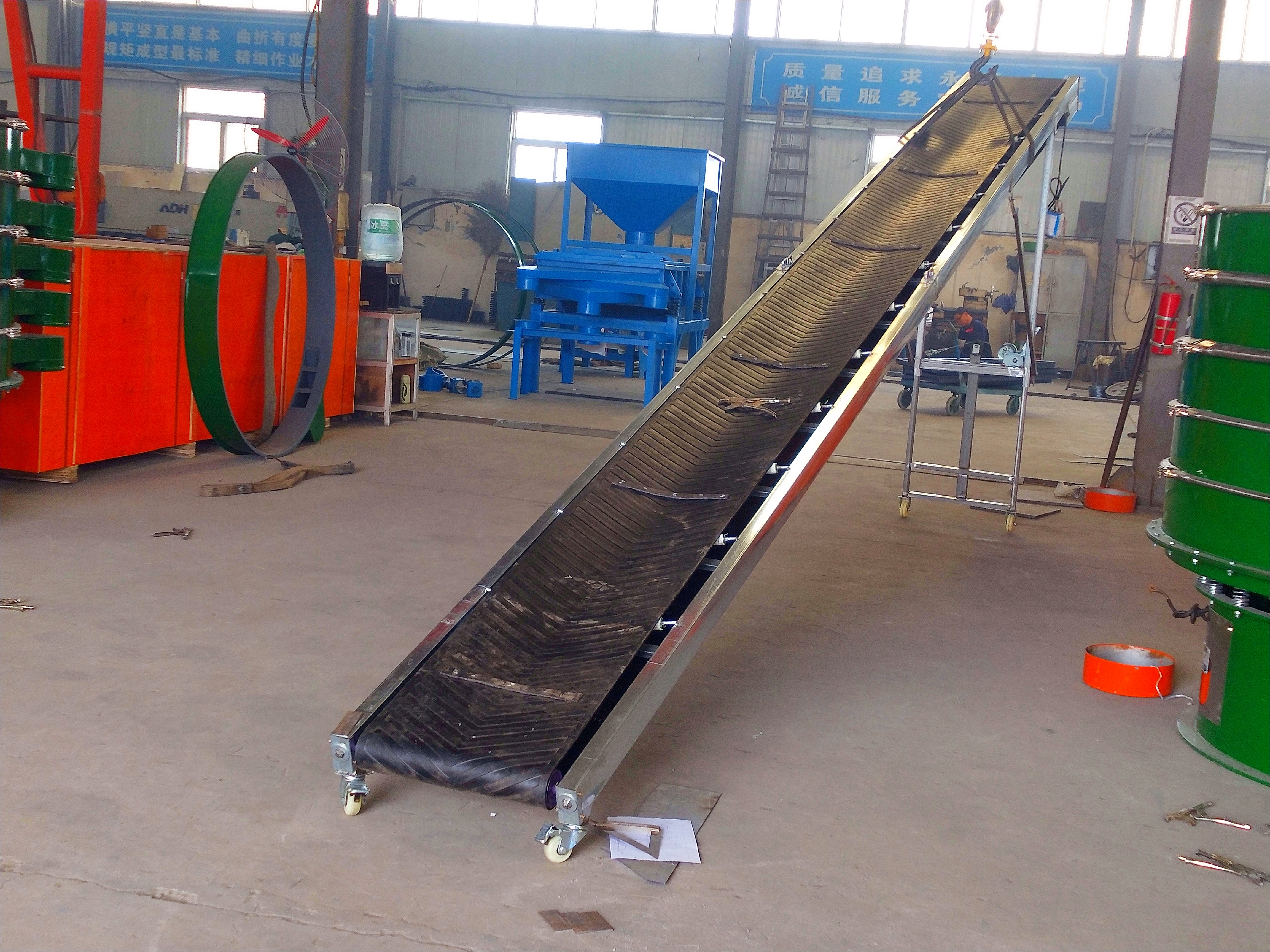

Corrugated sidewall conveyor belt |

|

Corrugated sidewalls are added on both sides of the belt body, and transverse partitions are set inside to form an independent hopper structure |

Vertical lifting with large inclination (up to 90°) |

Suitable for ore and grain Food and other lumpy/powdered materials |

|

Steel rope core conveyor belt |

|

High-strength steel wire rope is longitudinally embedded in the rubber belt body, and the surface is covered with a wear-resistant rubber layer |

Long-distance, heavy-load transportation |

High tensile strength, suitable for heavy-load, high-wear conditions |

|

Tubular conveyor belt |

|

The belt body is rolled into a round tube, and a support ring is installed inside |

Enclosed transportation of dusty materials, complex paths |

Rainproof and dustproof, reduce material spillage, and adapt to small radius turns |

|

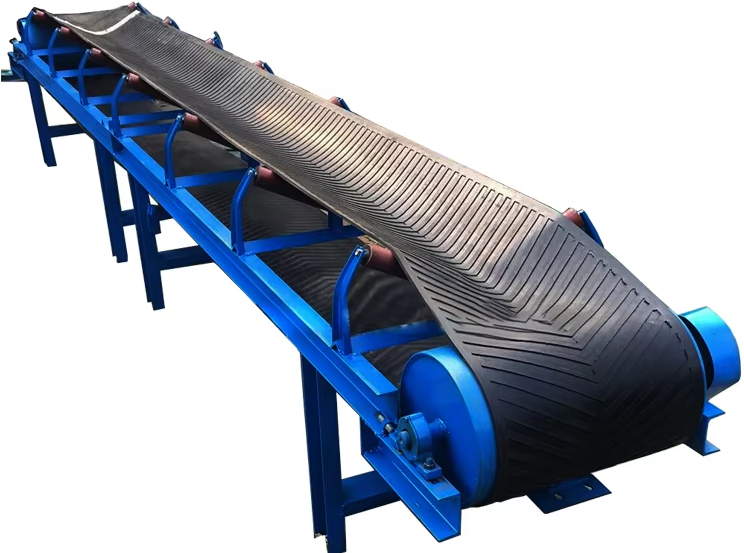

Pattern conveyor belt |

|

Herringbone, stripes or concave-convex patterns are pressed on the surface of the belt body |

Wet materials or steep slope transportation with high anti-slip requirements |

Increase friction and prevent materials from slipping, suitable for short distances and high-angle scenes |

Video of conveyor belt for lumpy materials

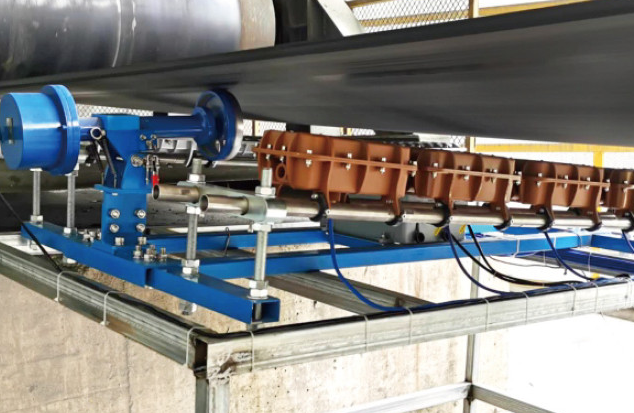

What is the working principle of conveyor belt for lumpy materials?

The working principle of conveyor belt for lumpy materials is to use the continuously circulating conveyor belt as a carrier, and under the traction of the drive device, realize the automatic transportation of materials from the loading point to the unloading point.

①Power transmission: The motor transmits power to the drive roller through the reducer or electric roller, and the friction between the drive roller surface and the conveyor belt drives the conveyor belt to move.

②Material loading and carrying: Materials are evenly placed on the conveyor belt through loading equipment.

③Continuous transportation: The conveyor belt runs at a constant speed, and the materials move to the designated position with the belt body. The roller system supports the conveyor belt and reduces the running resistance, and the tensioning device ensures the stability of the belt body tension.

④Material unloading: The material is unloaded at the conveyor belt terminal through the unloading device or natural throwing.

Features of conveyor belt for lumpy materials

24-hour uninterrupted operation: The conveyor belt can operate all-weather, with a theoretical utilization rate of more than 90%, significantly shortening the material turnover cycle.

Large conveying capacity design: Through wide belt width, high-speed belt (up to 5m/s) and grooved rollers (effective volume increased by 40%), the single-line hourly transportation capacity exceeds 5,000 tons.

Continuous operation capacity: No frequent start and stop, suitable for scenes such as mines and ports that require continuous feeding.

High carrying capacity: The transportation capacity of a single conveyor belt can reach 5,000 tons/hour (such as a steel cord belt with a bandwidth of 2m and a belt speed of 4m/s).

Compatible with large lumpys: can transport rocks with a maximum diameter of 1.5 meters (heavy-duty steel cable conveyor belt).

Anti-spill design: corrugated sidewall + transverse partition structure realizes 60° inclination conveying, and the material rolling rate is less than 3%.

Automated integration capability: can seamlessly connect loaders, crushers, and screening equipment to form a full-process automated production line and reduce manual intervention.

Related parameters of conveyor belt for lumpy materials

|

Type |

Maximum lumpy size |

Recommended belt speed (m/s) |

Temperature resistance range |

Allowable inclination angle |

Service life |

|

Wire rope core conveyor belt |

≤800mm |

1.6-4.0 |

-20℃~+60℃ |

≤18° |

3-8 years |

|

Corrugated sidewall conveyor belt |

≤300mm |

0.8-2.5 |

-10℃~+60℃ |

≤60° |

2-5 years |

|

Metal mesh belt |

≤500mm |

0.1-0.5 |

Normal temperature~800℃ |

≤30° |

5-10 years (shortened in high temperature environment) |

|

Ceramic Liner conveyor belt |

≤200mm |

1.0-2.0 |

-40℃~+120℃ |

≤25° |

5-7 years |

Comparison table of core advantages of conveyor belt for lumpy materials

|

Comparison items |

Ordinary conveyor belt |

conveyor belt for lumpy materials |

Advantage improvement |

|

Maximum lumpy processing capacity |

≤300mm |

≤1500mm |

500% |

|

Impact life |

1-2 years |

5-8 years (ceramic/steel cable belt) |

400% |

|

Allowable inclination |

≤18° |

≤90° (edge belt) |

500% |

|

Energy consumption per ton of material |

0.05-0.1 kWh/t |

0.02-0.04 kWh/t (frequency conversion energy saving) |

reduced by 50%-60% |

|

Comprehensive operation and maintenance cost |

high (frequent replacement of parts) |

low (long life + intelligent maintenance) |

reduced by 40%-70% |

Application of conveyor belt for lumpy materials

Conveyor belts for lumpy materials are widely used in various industries, covering multiple industries, especially mining, building materials, coal, metallurgy and other industries, especially in situations where large quantities of lumpy materials need to be transported quickly. lumpy materials usually refer to materials with irregular shapes, large particles or relatively hard materials. These materials need to be transported efficiently and safely with the help of equipment with load-bearing capacity and wear resistance during transportation.

Mining industry: Ore materials are often large in size, heavy in weight, irregular in shape, and require long-distance transportation. Conveyor belts for lumpy materials can withstand high-intensity and high-load transportation requirements, and transport ore from the mining point to the crushing, screening or storage area.

Construction industry: The transportation of materials such as sand, gravel, and limestone is an indispensable part of the production process. Conveyor belts can quickly transport these heavy materials from storage sites, crushers or screening equipment to construction sites.

Coal industry: Materials such as coal lumpys and coke usually need to be transported in large quantities and efficiently. The application of conveyor belts in the coal industry can realize the automated transportation of multiple links from mine excavation to processing, screening, stacking, etc., reducing the labor intensity and transportation costs of coal production.

Port and logistics industry: lumpy material conveyor belts are widely used for tasks such as ship unloading, material sorting and transportation. Conveyor belts can quickly transport lumpy materials (such as ore, coal, etc.) unloaded from ships to warehouses, yards or other transfer areas.

Fertilizer industry: Conveyor belts for lumpy materials are often used to transport coarse granular fertilizers, chemical raw materials or other solid materials. Since fertilizer production usually requires multiple processes, conveyor belts can efficiently transport materials between different processes to the next processing link.

Selection recommendations for conveyor belts for lumpy materials

Selecting a suitable conveyor belt for lumpy materials requires consideration of multiple factors, including material characteristics, working environment, transportation requirements and maintenance requirements. When selecting, the properties of the material (such as hardness, oiliness, slipperiness, etc.), the material of the conveyor belt (such as wear resistance, high temperature resistance, corrosion resistance, etc.), the conveying conditions (such as distance, inclination, load) and the convenience of equipment maintenance should be comprehensively considered.

|

Main conveyor line of open-pit mine |

coal loader at port |

clinker transportation of cement plant |

construction waste treatment line |

|

|

|

|

|

|

Iron ore (300mm) |

coal (50mm) |

clinker (50mm) |

concrete lumpy (200mm) |

|

Wire rope core conveyor belt, belt width 1.8m, belt speed 4m/s, driving power 500kW |

corrugated sidewall conveyor belt, belt width 1.4m, inclination 30°, vertical lifting 25m |

high temperature resistant conveyor belt, belt width 1.2m, temperature resistance 400℃, belt speed 2.5m/s |

trough conveyor belt, belt width 1.0m, belt speed 1.5m/s, iron remover installed |

Price of conveyor belt for lumpy materials

The price of conveyor belt for lumpy materials varies according to factors such as material, specification, brand, customization demand and market supply and demand.

To get an accurate price for conveyor belts for lumpy materials, you need to provide the following details:

Required conveyor belt type (e.g., ordinary type, wear-resistant type, skirt type, etc.)

Conveyor belt width, length and thickness

Required strength (tensile strength)

Material requirements for cover layer and belt core

Special performance requirements (e.g., heat resistance, wear resistance, acid and alkali resistance, etc.)

Purchase quantity

It is recommended that you contact Dahan suppliers directly or send an email to provide your specific needs, obtain detailed quotations and technical solutions, and select the most cost-effective product after comprehensive comparison.

My whatsapp: +86 15236742901, e-mail: sale@xxdahan.com