Portable Belt Conveyor

Portable belt conveyor is a lightweight, mobile material conveying equipment suitable for scenarios that require flexible deployment. Its core features are its flexibility and convenience, and it can be quickly deployed and used in different work locations.

What is a portable belt conveyor?

A portable belt conveyor is a modular, mobile, short-distance material conveying equipment designed for scenarios that require rapid deployment and flexible handling. It is widely used in multiple industries such as mines, construction sites, logistics, and agriculture. Its core advantages lie in modular design, lightweight structure (such as aluminum alloy) and foldable structure, which can be easily moved and deployed in different work scenarios, and is suitable for short-distance transportation of bulk materials or small and medium-sized materials. Compared with fixed conveyor belts, portable belt conveyors have higher flexibility and adaptability, and are particularly suitable for use in environments with limited space or frequent changes.

Applicable materials for portable belt conveyors

Portable belt conveyors are suitable for a variety of block, granular, powdered and packaged materials, especially in short-distance, temporary or frequently changing working environments. Due to its simple structure and flexible mobility, it is widely used in construction, agriculture, mining, docks, logistics and other industries.

Material type Typical example Maximum block size Recommended bandwidth Key technical requirements

Small and medium block materials Crushed stone, coal blocks, construction waste bricks ≤200mm 500-800mm

Granular/powdered materials Sand, cement, grain (wheat, corn) ≤50mm 400-650mm

Bagged/boxed materials Fertilizer bags, express cartons (≤50kg/piece) Single piece size ≤600×400mm 600-800mm

Lightweight and fluffy materials Straw bales, foam blocks, plastic particles ≤300mm

Types of portable belt conveyors

Portable belt conveyors can be divided into the following types according to their structure. Each type is designed for different needs. The following is a detailed classification and applicable scenarios:

Classification by structural form

Folding conveyor

Features: Three-stage folding design, height after storage <1.2 meters, can pass through standard door openings, and one person can complete deployment in 10 minutes. It can be folded for storage or movement, which is convenient for transportation and storage, and is suitable for temporary work sites.

Applicable scenarios: warehousing logistics, exhibition activities, temporary loading and unloading.

Case: An e-commerce warehouse uses a folding conveyor (500mm bandwidth, 4 meters length), which is quickly deployed to different sorting areas during Double 11, and the efficiency is increased by 50%.

Climbing conveyor

Features: The inclination angle is adjustable from 0 to 90°, equipped with anti-slip patterned belts and baffles, and the load-bearing capacity is ≤300kg. The conveyor belt angle is adjustable, suitable for loading and unloading materials that require a certain height difference.

Applicable scenarios: Floor transfer at construction sites, mining sample transportation.

Case: A construction site uses a climbing conveyor (30° inclination, 600mm bandwidth) to transport sand and gravel to the 3rd floor, replacing manual handling, and the cost is recovered in 3 months.

Telescopic conveyor

Features: Adjustable length (2-15 meters), hydraulic or electric drive telescopic, suitable for truck loading and unloading. Retractable structure, adjustable length, suitable for loading and unloading and other occasions with large changes.

Applicable scenarios: Logistics center, express sorting.

Case: A courier purchased a telescopic conveyor (800mm bandwidth, 2-10m telescopic range), which reduced the truck loading and unloading time by 40%.

Video of portable belt conveyor

What is the working principle of a portable belt conveyor?

The working principle of a portable belt conveyor is similar to that of a conventional belt conveyor. It mainly drives the roller to rotate through an electric motor, driving the conveyor belt (usually made of rubber, polyester or other high-strength materials) to move between two end points. The material is transported from one end (feed end) to the other end (discharge end) by the movement of the conveyor belt. The conveyor is usually equipped with an adjustment device to facilitate the adjustment of the angle and height of the conveyor belt to meet different work requirements.

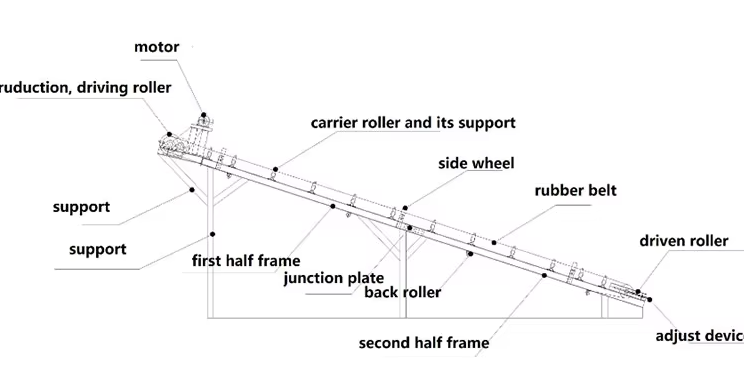

Mechanical composition of portable belt conveyor

The main components of a portable belt conveyor:

Conveyor belt: usually made of high-strength rubber, polyester or nylon, capable of carrying various types of materials.

Drive system: usually composed of an electric motor, a reducer and a drive roller to provide power for the conveyor belt.

Rollers and support frames: Rollers support the conveyor belt to keep it running smoothly and reduce friction.

Adjustment device: The angle and height of the conveyor belt can be adjusted to adapt to different transportation needs.

Mobile base: It is convenient for the equipment to move between different working positions, usually equipped with wheels or tracks.

What are the advantages of portable belt conveyors?

Modular design: The equipment structure is simple, and the length, width and angle of the conveyor belt can be adjusted as needed to meet the transportation needs of different occasions.

Lightweight structure: The weight of the whole machine is usually <200kg, and some models support manual push-pull or electric drive.

Multi-functional adaptation: The conveying height (0-90°), bandwidth (300-800mm) and length (2-15 meters) can be adjusted to meet diverse scenarios.

Flexible power: Supports electric (220V/380V) or lithium battery drive, and some models are equipped with wireless remote control function.

Wide range of applicable scenarios: Applicable to construction sites, mining, docks, logistics transportation, agricultural material transportation and other industries.

Quick deployment: One person can complete assembly or folding within 10-30 minutes to adapt to temporary transportation needs. It does not require complicated installation process and can be put into use quickly, which is suitable for temporary or short-term tasks.

Dimensions of portable belt conveyor

|

B |

D |

A |

L |

H |

C |

F |

d |

Size |

|

500 |

89 |

720 |

190 |

170 |

130 |

15 |

M12 |

204 |

|

650 |

870 |

240 |

||||||

|

800 |

1070 |

305 |

||||||

|

1000 |

108 |

1300 |

375 |

210 |

170 |

18 |

M12 |

305 |

|

1200 |

150 |

455 |

230 |

200 |

||||

|

1400 |

1750 |

525 |

Parameters of portable belt conveyor

|

Width(mm) |

Conveying length (m) Power (kw) |

Conveying speed(m/s) |

Conveying volume(t/h) |

||

|

400 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

30-60 |

|

3 |

3-4 |

4-7.5 |

|||

|

500 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

40-80 |

|

3 |

4-5.5 |

5.5-7.5 |

|||

|

650 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

80-120 |

|

4 |

7.5 |

7.5-11 |

|||

|

800 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

120-200 |

|

4 |

7.5 |

7.5-15 |

|||

|

1000 |

≤10 |

10-20 |

20-40 |

1.25-2.0 |

200-320 |

|

5.5 |

7.5-11 |

11-22 |

|||

|

1200 |

≤10 |

10-20 |

20-40 |

1.25-2.0 |

290-480 |

|

7.5 |

7.5-15 |

15-30 |

|||

|

1400 |

≤10 |

10-20 |

20-40 |

400-680 |

|

|

11 |

15-22 |

22-45 |

|||

|

1600 |

≤10 |

10-20 |

20-50 |

600-1080 |

|

|

15 |

22-30 |

30-75 |

|||

|

1800 |

≤10 |

10-20 |

20-50 |

1.0-2.0 |

800-1500 |

|

18.5 |

30-45 |

45-110 |

|||

|

2000 |

≤10 |

10-20 |

20-50 |

1000-2000 |

|

|

22 |

45-55 |

55-132 |

|||

|

2400 |

≤10 |

10-20 |

20-50 |

1500-3000 |

|

|

30 |

55-75 |

75-185 |

|||

Comparison table of portable belt conveyor selection

|

Model type |

Applicable scenario |

Maximum block size |

Conveying capacity |

Power configuration |

Weight |

Price range |

|

Light electric type |

Warehouse bag loading and handling |

≤50mm |

20-50t/h |

220V/2.2kW |

150-300kg |

$1,500-3,000 |

|

Medium diesel type |

Open-air construction site sand and gravel transportation |

≤150mm |

50-120t/h |

Diesel engine/5.5kW |

500-800kg |

$5,000-8,0 00 |

|

Heavy-duty explosion-proof type |

Emergency transportation in coal mines |

≤100mm |

30-80t/h |

Explosion-proof motor/4kW |

600kg |

$10,000+ |

|

Telescopic variable amplitude type |

Container loading and unloading |

≤200mm |

80-150t/h |

380V/7.5kW |

1000kg |

$12,000-18,000 |

Application of portable belt conveyor

Portable belt conveyor has high flexibility and adaptability, and is particularly suitable for those environments that require frequent changes in work locations or are restricted by space. It is widely used in many industries such as construction sites, mining, agriculture and logistics, and can efficiently transport block, granular or bulk materials.

Construction site: Material transportation usually requires frequent handling. Portable belt conveyors can be quickly deployed and easily moved between different corners of the construction site. They are used to transport materials such as sand, gravel, and concrete to the construction site or concrete mixing station.

Agricultural material transportation: It can be used to transport harvested grains from farmland to loading stations or warehouses, and it can also transport fertilizers or pesticides during agricultural production.

Mining: In open-pit mines or pits, belt conveyors can be flexibly moved according to the layout of the mine to transport mined ore or coal from the pit to the processing facility, which is particularly suitable for temporary or small-scale mining tasks.

Logistics warehousing: It can be used to transport goods from one stacking area to another, which is particularly suitable for cargo transportation that requires flexible layout.

Ports and docks: It is used to quickly transfer bulk cargo from ships to yards or other means of transportation, and can be flexibly adjusted according to changes in the position of the ship.

Related cases of portable belt conveyors

|

|

|

|

|

Construction sites |

Logistics storage centers |

Temporary storage during grain harvesting season |

|

|

|

|

|

Food processing plants |

Mine emergency |

Food processing plants |