Conveyor belt for sticky materials

Conveyor belt for sticky materials is a conveying equipment specially designed for conveying materials with high viscosity, easy adhesion or easy agglomeration. Its core is to prevent material adhesion, blockage and residue, and ensure efficient, stable and continuous conveying.

Conveying capacity: 30-3000 tons/hour

Operating speed: 0.5-4 meters/second

Inclination: 0-90° (depending on the design of the retaining edge)

Temperature range: -60℃ to +200℃ (depending on the material)

Applicable materials: syrup, mud, dough, wet powder, etc.

Material: PU, silicone, PTFE, rubber, stainless steel

What is a conveyor belt for sticky materials?

Conveyor belt for sticky materials is a conveyor belt specially designed for conveying materials with high adhesion. Such materials are easy to adhere to the surface of the conveyor belt during the conveying process, resulting in unclean unloading, reduced conveying efficiency, and even blockage. Therefore, the conveyor belt for sticky materials usually needs to have special anti-sticking properties and structural design.

Applicable materials for conveyor belt for sticky materials

Sticky materials usually have the characteristics of high humidity, strong adhesion, and easy adhesion to the conveyor belt surface. Common types include:

Mining industry: ore mud, concentrate powder, tailings slurry, wet coal powder, etc.

Chemical industry: fertilizer granules (wet state), polymer slurry, dye paste, etc.

Food industry: syrup, honey, jam, paste seasoning, wet starch, etc.

Building materials industry: cement raw material, wet sand, concrete aggregate, gypsum slurry, etc.

Agriculture/environmental protection: wine lees, drug residue, livestock and poultry manure, urban sludge, etc.

Types of conveyor belt for sticky materials

|

Conveyor belt type |

Picture |

material/structure |

advantages |

limitations |

|

PTFE coated belt |

|

glass fiber base cloth + Teflon coating |

anti-stick, high temperature resistance (260℃), easy to clean |

high cost, not resistant to mechanical scratches |

|

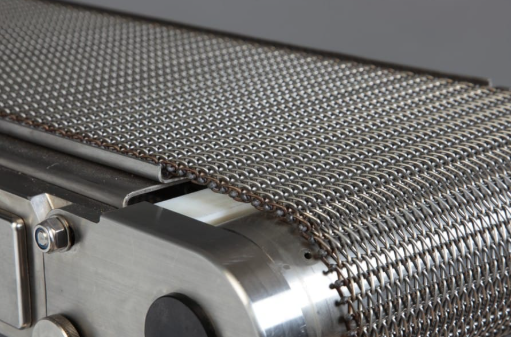

Stainless steel mesh belt |

|

304/316L stainless steel braid |

corrosion-resistant, breathable, can be washed at high temperature and high pressure |

heavy, not suitable for light load and high speed |

|

PU/PVC anti-stick belt |

|

polyurethane/polyvinyl chloride + smooth surface |

food grade, flexible, economical |

limited temperature resistance (usually <80℃) |

|

Modular plastic belt |

|

PP/PE module splicing |

opening holes for drainage, convenient local replacement |

low load capacity |

|

Pattern/convex rubber belt |

|

embossed or nail-like structure on the rubber surface |

increase friction, anti-slip |

slightly difficult to clean |

Conveyor belt for sticky materials video

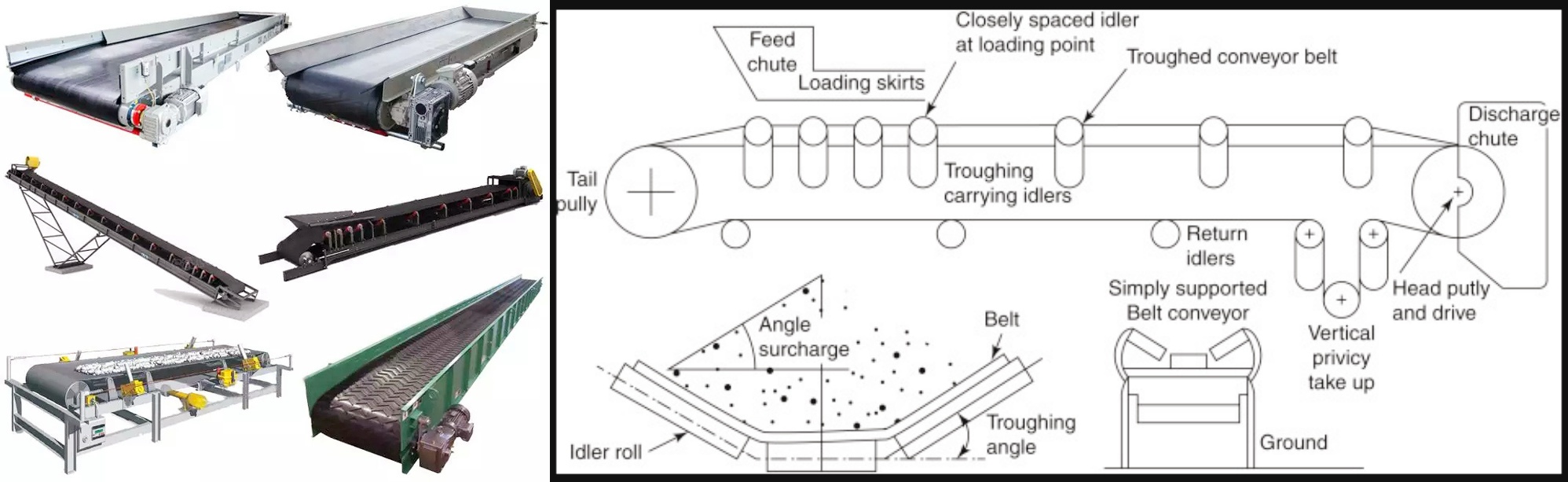

What is the structural composition of the conveyor belt for sticky materials?

The structural composition of the conveyor belt for sticky materials varies according to its type and application scenario, but usually includes a skeleton layer, a cover layer, an edge reinforcement layer, joints and other auxiliary structures (ribs, skirts, guide strips, etc.). The skeleton layer provides the strength and stability of the conveyor belt to ensure that it can withstand the weight and tension of the material during the conveying process. The cover layer is in direct contact with the material, protecting the skeleton layer from wear and corrosion, while providing good anti-stickiness. The edge reinforcement layer enhances the strength of the conveyor belt edge, prevents the material from overflowing from the edge, and protects the conveyor belt from edge wear.

Challenges faced by conveyor belt for sticky materials

① Material adhesion accumulation: The material sticks to the belt surface, resulting in unclean unloading and scaling, which will cause a decrease in conveying efficiency (frequent shutdown for cleaning), thereby breeding bacteria; the belt weight increases and the motor load increases.

② Difficult cleaning: Traditional cleaning tools (such as scrapers) cannot completely remove high-viscosity residues (such as asphalt and syrup), which will cause cross-contamination; corrode the belt skeleton.

③ Deviation and slippage: Uneven distribution of sticky materials leads to unbalanced belt tension, and wet sticky materials reduce the friction coefficient between the belt and the roller.

④ Blockage and backflow: Sticky materials slide down during large-angle conveying, and materials accumulate in narrow spaces (such as interfaces), eventually causing production line interruptions.

How to deal with the problems faced by conveyor belts for sticky materials?

In response to the above challenges, a variety of methods can be used to deal with the problems faced by conveyor belts for sticky materials to improve conveying efficiency and reliability:

Choose the right conveyor belt type and material:

Choose a conveyor belt material with a smooth surface and low friction coefficient, or use a conveyor belt with special patterns to reduce the contact area between the material and the conveyor belt for sticky materials and reduce adhesion. For example, patterns such as herringbone, diamond, and convex dots.

|

Material type |

Recommended belt |

Features |

|

Food (dough, sugar) |

Teflon coated belt/silicone belt |

Non-stick surface, easy to clean |

|

High temperature sticky materials (asphalt) |

Stainless steel mesh belt |

High temperature resistance (up to 800℃), corrosion resistance |

|

Chemical sticky materials (resin) |

Modular plastic belt (PP/PE) |

Acid and alkali resistance, removable for cleaning |

Install effective cleaning device: Select scraper cleaners of different materials and shapes according to the characteristics of the material, such as rubber scrapers, polyurethane scrapers, alloy scrapers, etc., installed near the head roller to scrape off the adhered materials.

Regular cleaning and maintenance: Establish a regular cleaning system, regularly check and replace worn cleaner parts to ensure its cleaning effect. Regularly check the tension and deviation of the conveyor belt for sticky materials and adjust them in time.

Material pretreatment: Properly pretreat the material before conveying, such as reducing the water content, adding anti-sticking agents, etc., to improve its fluidity and anti-sticking properties.

Technical specifications of conveyor belt for sticky materials

|

Project category |

Technical parameters/configuration options |

Project category |

Technical parameters/configuration options |

|

Applicable material types |

Wet sludge, sugar residue, bean residue, wine lees, paste chemical materials, tailings slurry, etc. |

Belt material |

PVC anti-stick belt, PU food belt, rubber skirt belt, PTFE Teflon belt, chain conveyor belt |

|

Belt width |

300mm–2000mm |

Conveying length |

2m–30m+ |

|

Conveying speed |

0.1–1.0 m/s |

Conveying inclination |

0°–30° (adding baffle is recommended for over 15°) |

|

Structural material |

Carbon steel spraying/stainless steel 304, 316 |

Cleaning system configuration |

Polyurethane scraper + brush roller/spray cleaning pipeline |

|

Scraper device type |

Manual pressure regulating type, automatic rebound type, spring loaded scraper |

Belt surface type |

Smooth surface/anti-slip pattern/food grade coating |

|

Roller structure |

Parallel rollers, grooved rollers, buffer rollers |

Enclosure |

Drip shield, sealing shield, material guide sealing chute |

|

Drive mode |

Reducer drive/electric roller |

Conveying capacity |

Determined by belt width + speed (common range 2–80 m³/h) |

|

Temperature application range |

-10℃~80℃ (conventional)/≤250℃ (high temperature PTFE belt) |

Optional functions |

Automatic deviation correction, deviation detection, PLC linkage, spray dust removal system |

Application of Conveyor belt for sticky materials

Due to its high adhesion and easy agglomeration, sticky materials are prone to residue, blockage or equipment wear during transportation. Conveyor belt for sticky materials uses anti-sticky materials (such as Teflon, silicone) and special structural design (such as sidewalls and guide strips) to effectively solve the problem of easy stickiness and difficult cleaning of traditional conveyor belts. Conveyor belts for sticky materials are widely used in food processing (dough, wastewater), sewage treatment (sludge), mining (wet coal, tailings), chemical industry (wet resin, adhesive), agriculture (wet grain, feed), building materials (wet slurry) and other scenarios.

Manufacturer of Conveyor belt for sticky materials

Dahan Machinery is a well-known domestic manufacturer of vibrating screens and conveying equipment, providing various industrial belt conveyors, chain conveyors, screw conveyors and other complete line equipment.

Service scope: Provide full-process service from design → manufacturing → installation → after-sales.

Support customization: Anti-sticking structure, closed anti-drip structure, food-grade belt, climbing and lifting structure, etc. can be customized according to user working conditions.

Contact information: You can contact the official website customer service or email to customize the equipment.

My whatsapp: +86 15236742901, e-mail: sale@xxdahan.com

Official website: https://www.dahanmachine.com