Belt Conveyor Copper Ore

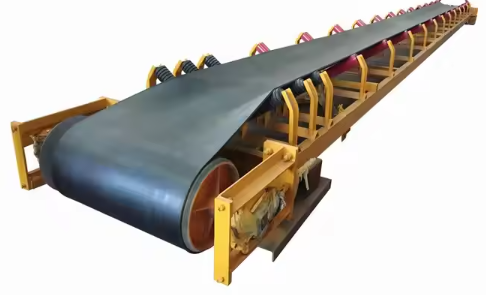

The belt conveyor copper ore is a common continuous transportation equipment in the mining and mineral processing industry. It is mainly used to transport the mined copper ore from the mining site, crushing station or yard to the next processing link (such as the mineral processing plant, grinding workshop, etc.).

Bandwidth: 650mm ~ 1600mm

Conveying capacity: 200 ~ 3000 t/h

Belt speed: 0.8 ~ 3.15 m/s

What is a belt conveyor copper ore?

The belt conveyor copper ore is a continuous conveying equipment designed for copper ore transportation. Copper ore usually has different particle sizes, different humidity, and exists in various forms such as block, granular and powder. The belt conveyor can effectively cope with these complex situations with its strong adaptability.

It is mainly composed of a driving roller, a redirecting roller and a closed conveyor belt. It is driven by an electric motor and relies on friction to drag the conveyor belt to realize the transportation of copper ore from the feeding end to the unloading end. The conveyor has the advantages of large conveying capacity, stable and reliable operation, and long conveying distance, which can meet the large-scale and continuous production needs of mines. In mining, it ensures the efficient and stable transportation of copper ore and is a key equipment in the material transportation link of mines.

Types of belt conveyors copper ore

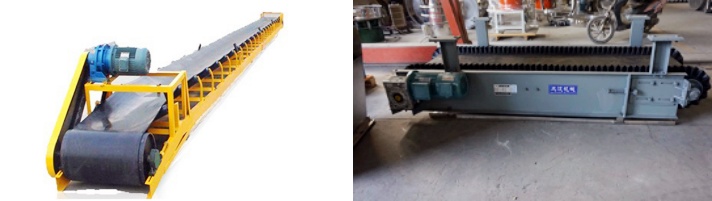

Fixed belt conveyor: It is a general series of products. It is a continuous conveying equipment with cotton canvas, nylon, polyester canvas and steel wire core conveyor belt as traction components. It can be widely used in mining, metallurgy, coal and other industries, and can meet the conditions of horizontal, lifting, and down-transportation. It can also adopt a conveying form with a combination of convex arc segments, concave arc segments and straight segments.

Air suspension belt conveyor: Using advanced aerodynamic principles, compressed air flow forms a 1-1.5mm air film on the belt auxiliary working surface, forming an "air cushion" effect, allowing the belt to float like riding an air cushion ship, completely subverting the traditional mechanical friction drive mode. It has the advantages of stable operation, eliminating dust overflow, reducing labor intensity, and low comprehensive energy consumption.

What is the purpose of the belt conveyor copper ore?

To achieve efficient transportation of copper ore: After mining, copper ore usually needs to be transported from the mining point to the crushing station, ore dressing plant or storage yard. The belt conveyor can continuously transport copper ore over long distances and in large quantities, greatly reducing the use of intermittent transportation methods such as manual or loader.

Connecting various process links: In the entire production process of copper mines, belt conveyors play the role of "links" and are used to connect multiple key operation points, such as:

① Transporting raw ore from the mining area to the coarse crushing workshop

② Transporting from the crusher to the screening system or grinding equipment

③ Transporting from the beneficiation equipment to tailings treatment or concentrate storage

④ Transporting from the ore bin to the loading station or loading dock

Adapting to the needs of large-scale production in mines: Copper mine production is generally a high-yield, continuous operation mode. Belt conveyors have a strong conveying capacity (up to thousands of tons/hour) to meet the needs of 24-hour uninterrupted operation in mines.

Adapting to complex terrain and multiple transportation directions: Copper mines are widely distributed, and the transportation paths often involve long distances, high drops, turns, inclinations and other complex routes. Belt conveyors can be flexibly configured to adapt to a variety of installation methods (ground, overhead, underground, etc.) to meet the transportation tasks under complex working conditions.

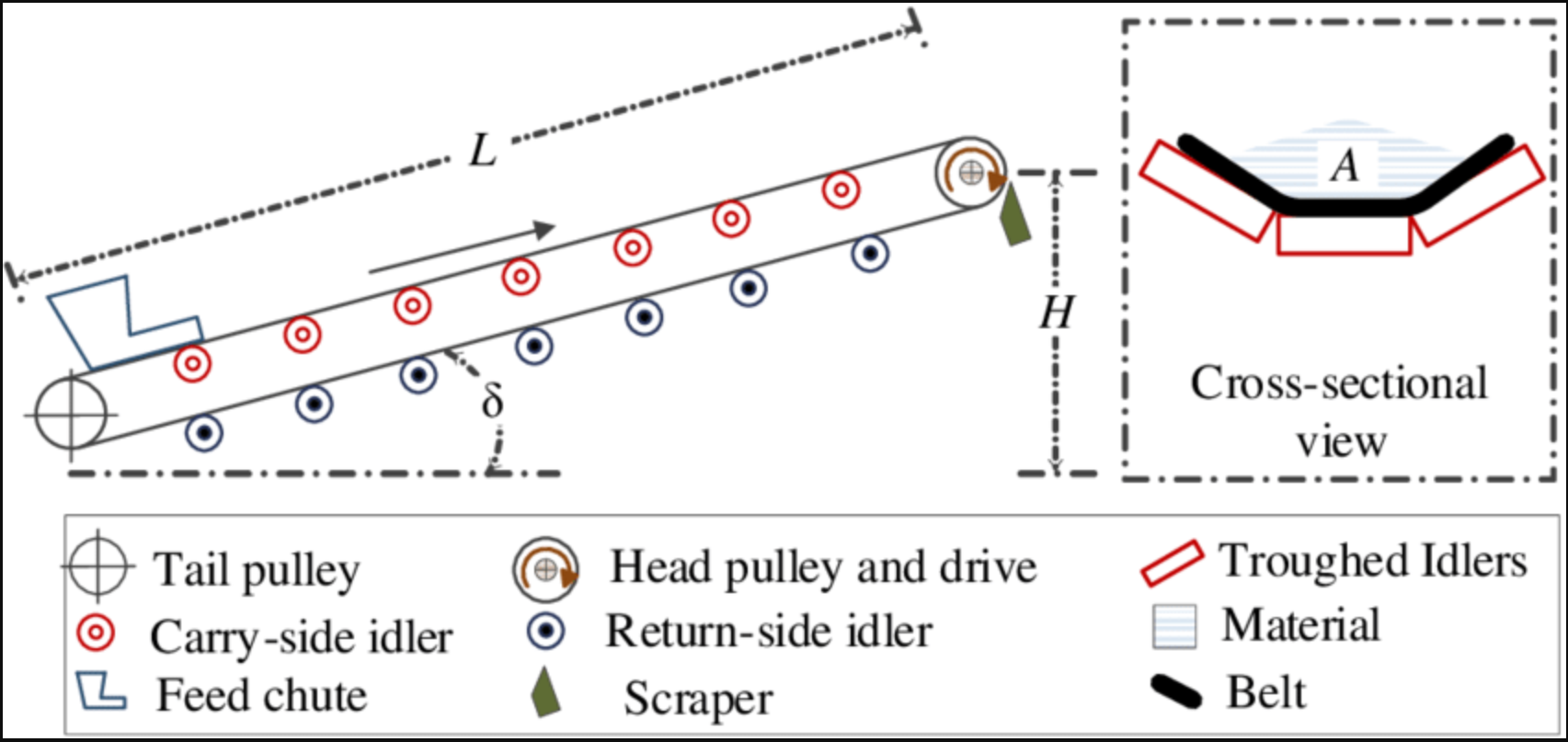

Working principle of belt conveyor copper ore

It is mainly composed of two end rollers and a closed conveyor belt tightly sleeved on them. The roller that drives the conveyor belt is called the drive roller, and the other roller that is only used to change the direction of the conveyor belt is called the redirection roller. The drive roller is driven by the motor through the reducer, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt. The drive roller is generally installed at the discharge end to increase the traction force and facilitate dragging. The material is fed from the feeding end, falls on the rotating conveyor belt, and is driven by the friction of the conveyor belt to be transported to the discharge end for discharge.

Technical specifications of belt conveyor copper ore

|

Width (mm) |

Conveying length (m) Power (kw) |

Conveying length (m) Power (kw) |

Conveying length (m) Power (kw) |

Conveying speed (m/s) |

Conveying volume (t/h) |

|

400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 |

30-60 |

|

500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 |

40-80 |

|

650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 |

80-120 |

|

800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 |

120-200 |

|

1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 |

200-320 |

|

1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 |

290-480 |

|

1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 |

400-680 |

|

1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 |

600-1080 |

|

1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 |

800-1500 |

|

2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 |

1000-2000 |

|

2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 |

1500-3000 |

What can belt conveyor copper ore be used for?

Belt conveyor copper ore is a continuous conveying equipment widely used in mining and ore processing. Its main function is to realize the efficient and stable transportation of copper ore from one process link to another to meet the needs of large-scale ore transportation.

Mining site transportation: In open-pit or underground mines, the copper ore after blasting or excavation is transported from the mining face to the primary selection plant (such as the crushing workshop) to complete the initial material handling. Adapt to the complex terrain of the mine (such as slopes and curves), realize long-distance transportation of ore, and reduce manual handling costs and efficiency losses.

Material transmission in the ore dressing process: transport the coarsely crushed and medium-crushed ore to the screening equipment to achieve the classification of ores of different particle sizes. Transport the crushed ore to the ball mill, flotation machine and other equipment to complete the grinding and ore dressing operations to form copper concentrate or tailings.

Concentrate and tailings treatment: transport the copper concentrate after ore dressing to the concentration and filtration workshop, or directly transport it to the smelter for further processing. Transport the tailings sand after ore dressing to the tailings pond or tailings treatment facility to achieve safe disposal of waste.

Storage and loading and unloading links: In the mine storage area, the ore is evenly stacked in the material yard, or the material is taken from the material yard and transported to the transport vehicle (such as trucks and trains) for external transportation. At the copper ore export port, cooperate with other equipment (such as ship loaders) to load the ore into the cargo ship to complete the connection between water and land transportation.

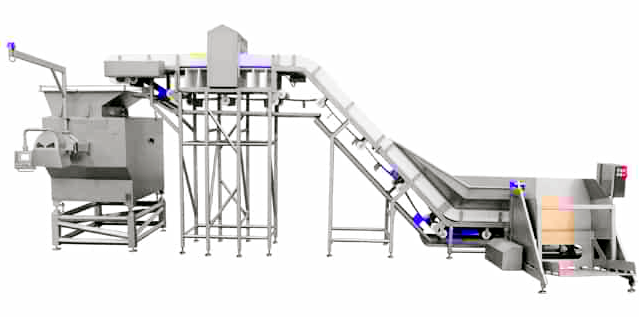

Belt Conveyor Copper Ore System

The belt conveyor copper ore system is a kind of equipment specially designed for transporting copper ore and related materials, which is widely used in copper mining, mineral processing and logistics. Through efficient and stable material transmission, it runs through the whole process of mining, mineral processing, warehousing and transportation, significantly improving production efficiency, reducing costs and ensuring safety. With the development of intelligent mining, belt conveyors will further integrate intelligent sensing, unmanned control and other technologies in the future, becoming the key support for green mine construction.