Belt Conveyor Iron Ore

Belt conveyor iron ore is a continuous equipment suitable for high-intensity material transportation, especially for raw materials such as limestone with high bulk density, strong abrasiveness and high dust.

Product Description

Limestone has the characteristics of high hardness (Mohs hardness 3-4), uneven particle size, high dust content and high density (about 2.6-2.8g/cm³), which puts high requirements on the structural strength and wear resistance of the conveying equipment. Belt conveyor iron ore usually adopts steel wire rope core or multi-layer canvas core wear-resistant conveyor belt, equipped with reinforced rollers and thickened frame to improve stability and durability under high load and high intensity conditions.

Belt conveyor iron ore is a continuous transportation equipment specially used for conveying bulk materials such as iron ore and limestone. It drives the belt to circulate through the motor to efficiently transport limestone and other materials from one place to another. It is widely used in mining, metallurgy and port industries.

Material properties of limestone and equipment adaptation

① Hardness and particle size

The Mohs hardness of limestone is about 3-4, and its texture is soft but brittle. During transportation, it is necessary to avoid excessive extrusion to cause pulverization. The equipment uses buffer rollers and low-speed operation mode to reduce the material breakage rate.

The particle size range is wide (powder to 300mm block stone). The equipment can adapt to different particle sizes through variable groove angle rollers (groove angle 15°-45° adjustable) to prevent material spillage.

② Humidity and adhesion: When the water content of limestone is high, it is easy to adhere to the conveyor belt. The equipment is equipped with a cleaning device (such as a polyurethane scraper) and a vibrating feeder to ensure clean unloading and avoid carrying material back.

③ Corrosiveness: Limestone is slightly soluble in water, and long-term contact may corrode metal parts. The key parts of the equipment (such as rollers and roller brackets) are treated with stainless steel or anti-corrosion coatings to extend the service life.

Scope of application of belt conveyor iron ore

Belt conveyor iron ore is suitable for conveying the following types of materials:

Large pieces of iron ore (such as raw ore after mining);

Small and medium-sized particles of ore after crushing;

Concentrate powder (dust cover or closed conveying structure is required);

Water-containing ore (pay attention to the anti-slip and water-resistant properties of the belt body).

How does the belt conveyor iron ore work?

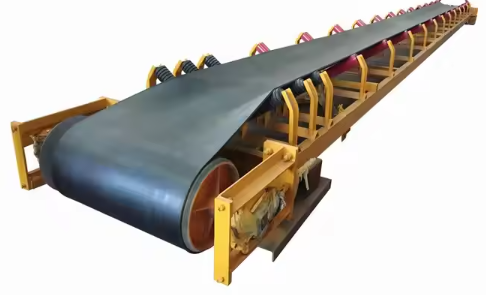

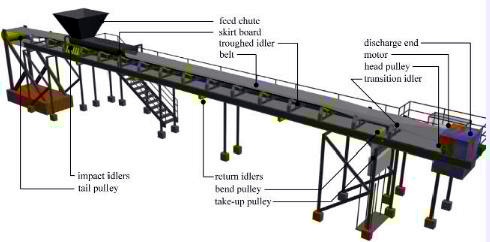

The belt conveyor iron ore is mainly composed of a frame, a conveyor belt, rollers, rollers, tensioning devices, transmission devices, etc. The roller that drives the conveyor belt to rotate is called a drive roller, and the other roller that is only used to change the direction of movement of the conveyor belt is called a redirecting roller.

The drive roller is driven by an electric motor through a reducer, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt. The drive roller is generally installed at the discharge end to increase traction and facilitate dragging. The material is fed from the feeding end, falls on the rotating conveyor belt, and is driven by the friction of the conveyor belt to be transported to the discharge end for discharge.

What are the advantages of belt conveyor iron ore?

Belt conveyor iron ore has become the core equipment of mine transportation due to its high efficiency and adaptability. Its advantages include: large-volume continuous transportation, a single machine capacity of more than 5,000 tons/hour, 24-hour uninterrupted operation, significantly reducing manual intervention and transportation costs; strong wear-resistant design, using multi-layer steel wire core conveyor belt and buffer rollers to resist the impact of sharp edges and corners of iron ore, and the service life is 3-5 times longer than that of ordinary conveyor belts; strong terrain adaptability, horizontal -30° inclination flexible layout, can bypass obstacles or directly connect to crushing and screening systems, shortening the process flow; low-energy consumption and environmentally friendly operation, electric drive saves more than 60% energy compared to truck transportation, with closed guide trough and dry fog dust suppression technology, dust emission concentration is less than 10mg/m³; intelligent maintenance guarantee, real-time monitoring of belt tension, deviation and tearing, failure rate reduced by 40%, maintenance cost reduced by 30%. Suitable for long-distance (up to 30 kilometers) and high-load iron ore transportation scenarios.

Common models and parameter ranges

Belt conveyor iron ores have various models and configurations depending on the conveying capacity, conveying distance and use environment. Common model parameters are as follows:

|

Model example |

Belt width (mm) |

Conveying capacity (t/h) |

Belt speed (m/s) |

Maximum conveying length (m) |

Maximum inclination (°) |

|

DH500 |

500 |

80–150 |

0.8–1.6 |

≤100 |

≤12 |

|

DH800 |

800 |

200–400 |

0.8–2. 0 |

≤200 |

≤15 |

|

DH1000 |

1000 |

400–800 |

1.0–2.5 |

≤300 |

≤18 |

|

DH1200 |

1200 |

500–1000 |

1.2–3.15 |

≤500 |

≤20 |

|

DH1400 |

1400 |

800–1500 |

1.2–3.15 |

≤600 |

≤20 |

Note: The high-angle sidewall belt conveyor can achieve an inclination of more than 30°, which is suitable for short-distance and high-inclination conveying occasions.

Application of belt conveyor iron ore

Limestone mine: transports blasted or crushed limestone to crushing station, screening station or storage yard;

Cement plant: transports limestone from the yard to the clinker production line, which is the key equipment in the raw material preparation process;

Steel plant: as part of the iron ore and limestone combined conveying system, it is used for material transportation from the raw material yard to the blast furnace;

Lime production line: used for stable supply of limestone from the ore bin to the lime kiln.