Concrete Belt Conveyor

Concrete belt conveyor is a mechanical equipment specially used for horizontal or inclined conveying of concrete mixtures. It is widely used in construction sites, concrete prefabricated component plants, road construction and other fields. Its core function is to efficiently and stably transport concrete from a mixing plant or storage point to a designated location through a continuously running conveyor belt.

Conveying capacity: 1280 cubic meters per hour

Conveying length: 230 meters

Selection angle: horizontal large inclination (≤90°)

What is a concrete belt conveyor?

Concrete belt conveyor is a mechanical equipment used for continuous conveying of granular or wet materials such as concrete. It is widely used in construction projects, prefabricated component plants and tunnel construction. The equipment is mainly composed of a conveyor belt, a drive device, a roller, a frame and a tensioning system. Its conveying capacity can reach 30 to 300 cubic meters per hour. The conveyor belt width is commonly 500 to 1200 mm, and the belt speed is 0.8 to 2.5 m/s. The equipment is usually suitable for conveying operations with an inclination of no more than 20°. If the inclination needs to be increased, it can be equipped with a corrugated sidewall. In addition, to ensure the quality of concrete, some systems are also equipped with screening devices. The screening mesh is generally 4 to 10 meshes, which are used to remove impurities and coarse particles in aggregates, improve conveying efficiency and concrete uniformity.

Types of concrete belt conveyors

|

Category |

Picture |

Structural form |

Applicable scenarios |

Features |

|

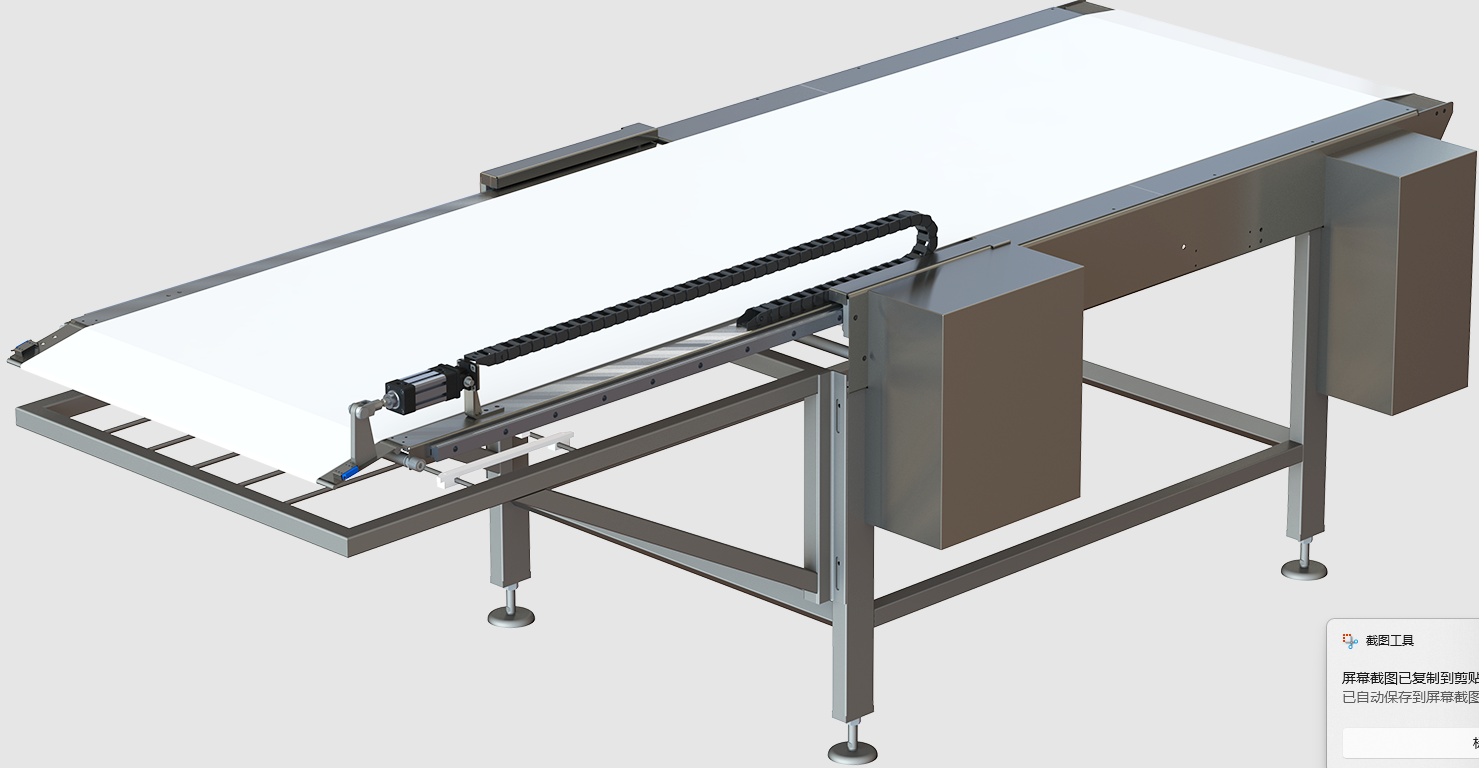

Fixed belt conveyor |

|

Frame fixed installation |

Mixed station, ground construction |

Stable structure, suitable for long-term, fixed-point operations |

|

Mobile belt conveyor |

|

With tire base or crawler base |

Temporary sites such as construction sites, tunnels, bridges, etc. |

Can quickly transfer positions to adapt to complex construction sites |

|

Retractable belt conveyor |

|

Adjustable length structure |

Multi-layer casting, high and low drop transportation |

Adjustable conveying length to adapt to different height differences of working surfaces |

|

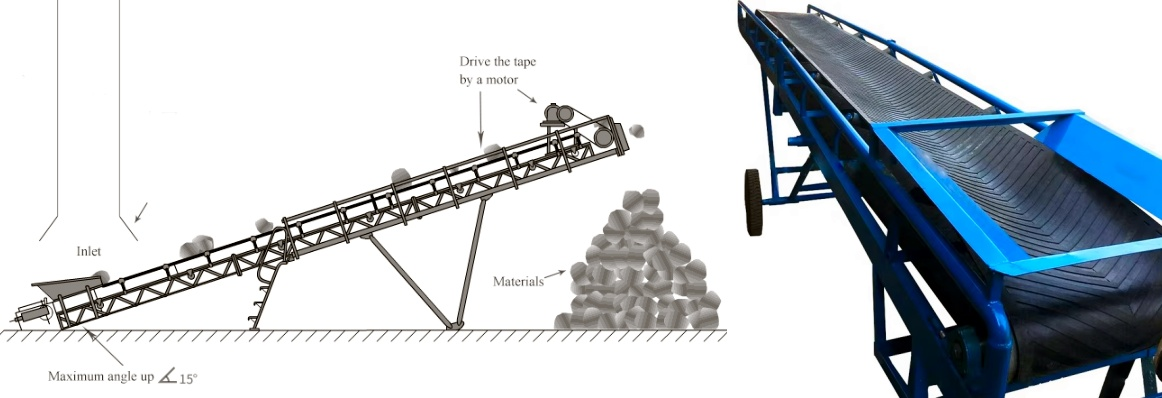

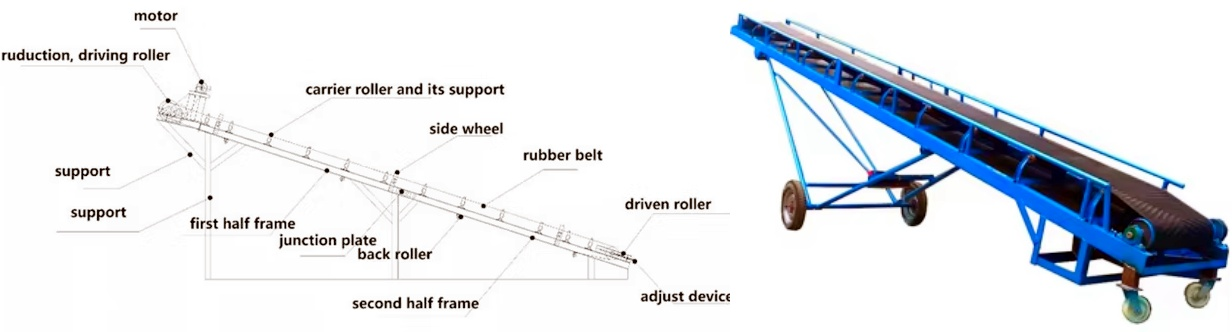

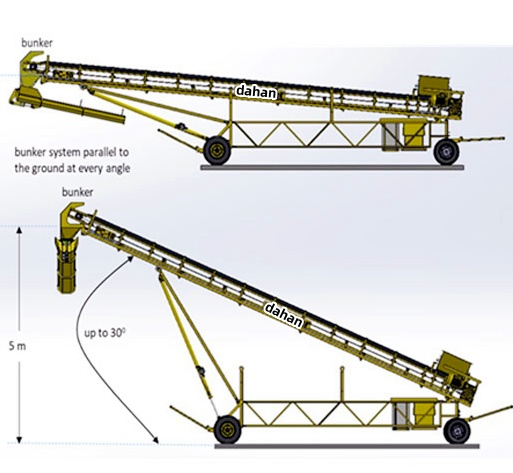

Inclined belt conveyor |

|

Adjustable inclination |

Bin loading, high-altitude feeding |

Large conveying inclination, saving space, often used with elevators |

|

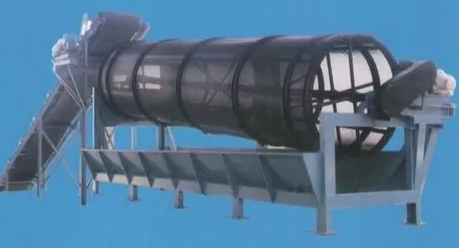

Conveyor with screening device |

|

Equipped with screen or vibrating screen |

Working conditions with control requirements for material particle size |

Can simultaneously realize conveying and preliminary screening to improve concrete quality |

Applicable materials for concrete belt conveyors

Concrete belt conveyors are mainly suitable for the following materials:

①Concrete: commercial concrete of various mix ratios, self-mixed concrete, etc.

②Sand and gravel aggregate: aggregates of different particle sizes such as sand, gravel, crushed stone, etc.

③Cement: bulk cement.

④Other building materials: mortar, mortar, etc.

When conveying aggregates, screening equipment is sometimes equipped at the feed end to remove oversized particles or impurities to ensure the quality of concrete. According to different conveying capacity requirements, the bandwidth and belt speed of the concrete belt conveyor will be different. The common conveying capacity range can reach tens to hundreds of cubic meters per hour.

Video of concrete belt conveyor

What is the working principle of the concrete belt conveyor?

The working principle of the concrete belt conveyor mainly relies on friction to achieve continuous conveying of concrete, as follows:

The motor in the drive device transmits power to the active roller through transmission parts such as the reducer. The active roller starts to rotate under the action of power.

There is friction between the active roller and the conveyor belt. When the active roller rotates, the conveyor belt is driven by friction. The conveyor belt passes through the active roller, the redirecting roller, etc. to form a closed ring, and maintains a stable running track under the support of the upper and lower rollers.

Concrete is placed on the conveyor belt. Due to the friction between the conveyor belt and the concrete and the cohesion of the concrete itself, the concrete is transported forward with the movement of the conveyor belt. During the conveying process, the rollers support the conveyor belt and concrete, reduce the sagging and wear of the conveyor belt, and ensure the smoothness of the conveying.

When the conveyor belt runs to the unloading position, the concrete is unloaded from the conveyor belt under the action of gravity and reaches the designated pouring site or storage area.

Structural composition of concrete belt conveyor

Conveyor belt: wear-resistant, corrosion-resistant, oil-resistant rubber belt or polyurethane belt, suitable for wet and corrosive concrete environment.

Drive device: generally electric roller or motor + reducer, providing the power required for belt conveying.

Roller and roller: support the operation of the conveyor belt, the roller must have good sealing and wear resistance to prevent concrete adhesion and clogging.

Tensioning device: maintain the tension of the conveyor belt, common spiral and heavy hammer tensioning structures.

Frame: generally adopts steel structure, stable and reliable, easy to install and move on site.

Cleaning device: set at the tail or return section, used to clean the residual concrete on the conveyor belt.

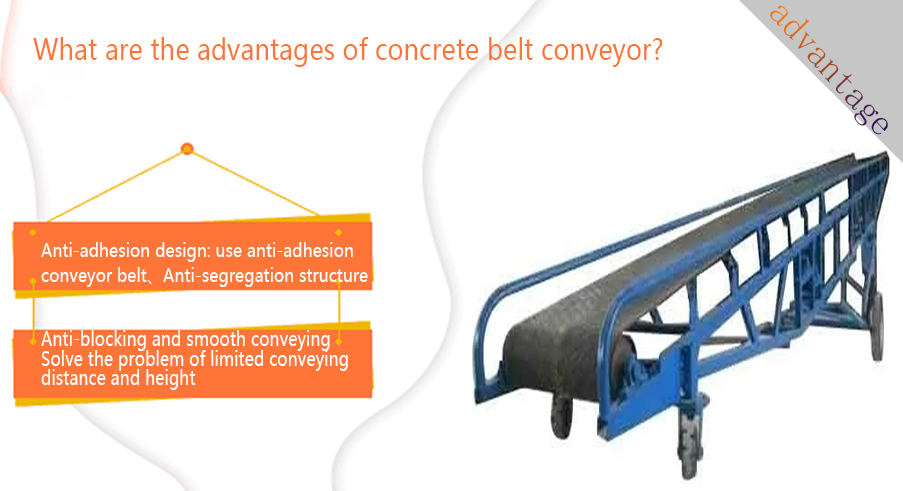

What are the advantages of concrete belt conveyor?

Anti-adhesion design: use anti-adhesion conveyor belt: usually made of rubber or polyurethane, with smooth surface and wear resistance, to reduce concrete adhesion.

Anti-segregation structure: reasonable conveying speed and angle control, reduce the running speed, limit the inclination angle within 20°, avoid the stratification of concrete aggregate and slurry, maintain the integrity of concrete, and improve the pouring quality.

Anti-blocking and smooth conveying: smooth structure, no dead corners of material accumulation: the inner wall of the frame is smooth, the material is not easy to be retained, and the inlet and outlet are reasonably designed to ensure smooth material flow and prevent bridge blockage or overflow.

Solve the problem of limited conveying distance and height: the belt conveyor can be flexibly arranged and adjusted in height according to the needs of the project, and can easily achieve long-distance and high-altitude conveying through multi-section series connection, climbing conveyor belt and other methods.

Technical parameters of concrete belt conveyor

|

Width (mm) |

Conveying length (m) Power (kw) |

Conveying length (m) Power (kw) |

Conveying length (m) Power (kw) |

Conveying speed (m/s) |

Conveying volume (t/h) |

|

400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 |

30-60 |

|

500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 |

40-80 |

|

650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 |

80-120 |

|

800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 |

120-200 |

|

1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 |

200-320 |

|

1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 |

290-480 |

|

1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 |

400-680 |

|

1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 |

600-1080 |

|

1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 |

800-1500 |

|

2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 |

1000-2000 |

|

2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 |

1500-3000 |

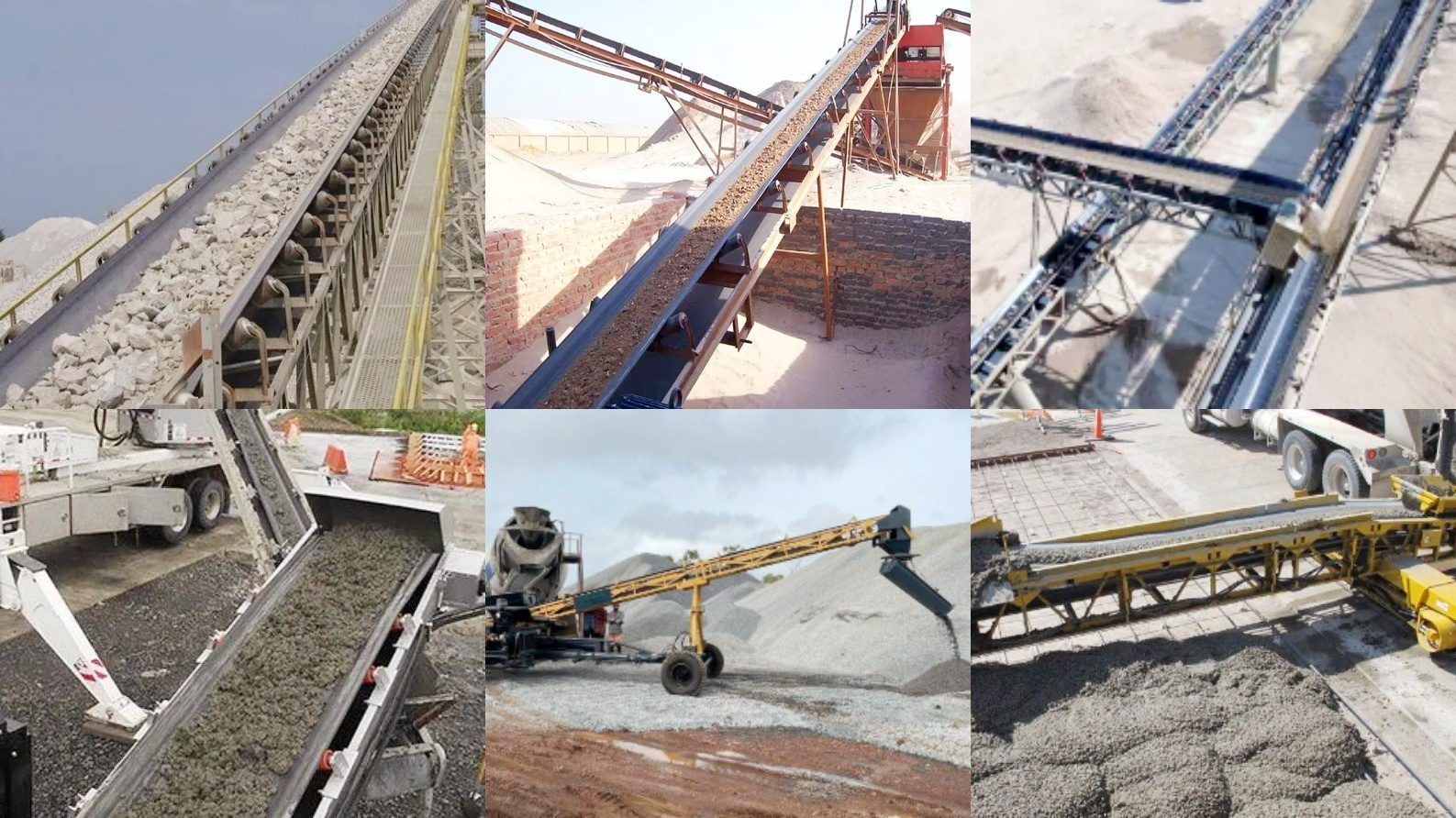

What can concrete belt conveyor be used for?

Concrete belt conveyor is a continuous transport equipment specially used for conveying concrete, which is widely used in engineering fields such as construction, water conservancy, and transportation. Its core function is to efficiently and stably transport concrete to the designated location, which is especially suitable for large-scale or long-distance construction scenes.

Concrete transportation at construction sites

Bridge casting section material yard feeding

Metro and tunnel engineering concrete transportation

Commodity concrete mixing station transportation link

Precautions for concrete belt conveyor

Concrete has a certain viscosity, and the conveyor belt needs to have good wear resistance and anti-sticking ability.

After long-term use, it should be cleaned in time to prevent the concrete from solidifying on the equipment.

When the inclination angle is too large, a corrugated sidewall conveyor belt should be used to prevent the concrete from sliding down.

The tensioning device and motor cooling should be checked regularly.