Fabric reinforced conveyor belt

Fabric reinforced conveyor belts are made by embedding one or more layers of high-strength textile fabric layers (such as polyester, nylon, cotton canvas, etc.) in a rubber base material, and compounded through processes such as calendering and vulcanization. The fabric layer plays a role in enhancing tensile strength and tear resistance.

Product Description

The fabric reinforced conveyor belt is a flexible composite conveyor belt made of fabric as a reinforcing skeleton material and rubber or plastic as a base material. Its belt core (the load-bearing frame of the belt) is made of one or more layers of woven fabric. This fabric reinforcement structure gives the belt excellent tensile strength, elongation (stretching) resistance and the ability to withstand the stress of conveyed materials. The fabric core is usually wrapped in a rubber or other elastomer or plastic outer layer to protect it from wear, abrasion, moisture and the impact of conveyed materials.

Different types of fabric reinforced conveyor belts

|

Fabric reinforced conveyor belt |

Sidewall conveyor belts |

Steel cord conveyor belts |

|

|

|

|

|

Fabric conveyor belts, or textile conveyor belts as they are also called, are used principally for heavy-duty, abrasive materials |

Sidewall conveyor belts are a space-saving and energy-efficient way to transport material |

Steel cord conveyor belts have high wear resistance and are mainly used for long-distance transportation, heavy loads and transportation that requires high physical strength |

|

Aramid conveyor belts |

Chevron conveyor belts |

Pipe conveyor belts |

|

|

|

|

|

Long lasting, energy saving belts |

Effectively keep loose material in place, even at steep angles with our chevron conveyor belts |

Pipe conveyor belts, or tube conveyor belts, are used for enclosed material transport |

Video of fabric reinforced conveyor belts

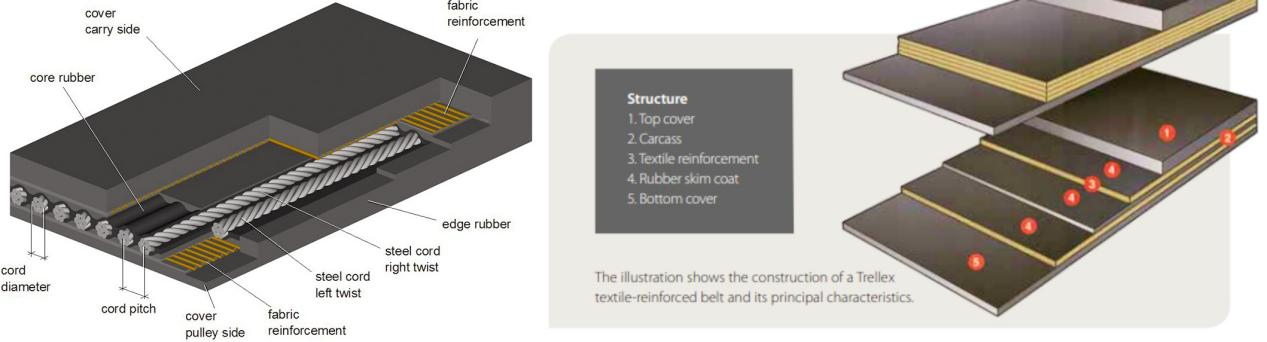

What is the structure of fabric reinforced conveyor belts

Fabric reinforced conveyor belts are usually composed of an upper covering rubber layer (contacting materials, wear-resistant and anti-corrosion), a fabric skeleton layer (enhancing the tensile strength of the belt body), a lower covering rubber layer (supporting the contact roller, wear-resistant and fatigue-resistant), a bonding layer (in a multi-layer belt, connecting each fabric layer) and an edge glue (optional, to prevent delamination).

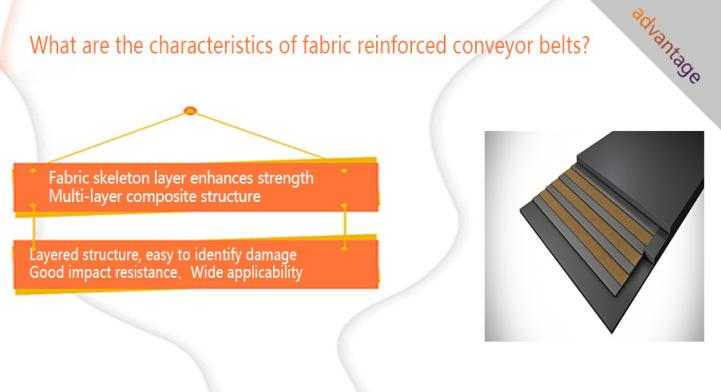

What are the characteristics of fabric reinforced conveyor belts?

Fabric skeleton layer enhances strength: high-strength synthetic fibers (such as EP, NN, CC) are used as skeleton materials; enhance the tensile strength and tear resistance of the conveyor belt.

Multi-layer composite structure: upper and lower covering rubber layers and multi-layer fabric cores are combined and applied, and the number of layers can be customized according to needs (2 to 6 layers are common).

Layered structure, easy to identify damage: The structure of multi-layer fabrics can more easily judge the degree and scope of damage when local damage occurs.

Good impact resistance: The multi-layer fabric structure can disperse and absorb impact force, so that it has a certain impact resistance when conveying blocky or irregular materials, reducing damage caused by impact.

Wide applicability: By selecting different types of fabrics (such as cotton, nylon, polyester, aramid, etc.) and covering rubbers with different properties, fabric reinforced conveyor belts can adapt to various conveying environments and material properties, such as wear resistance, heat resistance, oil resistance, corrosion resistance, etc.

Technical specifications of fabric reinforced conveyor belts

|

BELT TYPE |

TOP |

BOTTOM |

THICKNESS |

WEIGHT |

BELT WIDTH |

|

DH 160/2 |

2 mm |

1 mm |

4.6 mm |

5.6 kg/m2 |

300 - 1300 mm |

|

DH 200/2 |

2 mm |

1.5 mm |

5.6 mm |

6.4 kg/m2 |

300 - 1400 mm |

|

DH 250/2 |

3 mm |

1 mm |

6.3 mm |

7.7 kg/m2 |

400 - 1600 mm |

|

DH 250/2 |

3 mm |

1.5 mm |

6.8 mm |

8 kg/m2 |

400 - 1400 mm |

|

DH 315/2 |

4 mm |

1.5 mm |

79 mm |

9.4 kg/m2 |

500 - 1600 mm |

|

DH 315/3 |

3 mm |

1.5 mm |

7.3 mm |

8.2 kg/m2 |

800 mm |

|

DH 400/2 |

3 mm |

1 mm |

6.7 mm |

8.5 kg/m2 |

650 - 1600 mm |

|

DH 400/2 |

5 mm |

1.5 mm |

9.4 mm |

11.3 kg/m2 |

650 - 1600 mm |

|

DH 400/3 |

3 mm |

1 mm |

6.8 mm |

8.2 kg/m2 |

400 - 1000 mm |

|

DH 400/3 |

4 mm |

2 mm |

8.8 mm |

10.4 kg/m2 |

500 - 1200 mm |

|

DH 500/3 |

5 mm |

1.5 mm |

9.4 mm |

11.1 kg/m2 |

600 - 1600 mm |

|

DH 500/4 |

3 mm |

1 mm |

7.8 mm |

9.4 kg/m2 |

1000 - 1200 mm |

|

DH 500/4 |

4 mm |

2 mm |

9.8 mm |

11.6 kg/m2 |

1200 - 1400 mm |

|

DH 500/4 |

5 mm |

2 mm |

10.8 mm |

12.8 kg/m2 |

650 - 1000 mm |

|

DH 500/4 |

6 mm |

2 mm |

11.8 mm |

13.9 kg/m2 |

800 mm |

|

DH 630/4 |

5 mm |

2 mm |

11 mm |

13 kg/m2 |

2000 - 2400 mm |

|

DH 630/4 |

6 mm |

2 mm |

12 mm |

14.1 kg/m2 |

800 - 1200 mm |

|

DH 630/4 |

8 mm |

3 mm |

15 mm |

17.7 kg/m2 |

1000 - 1400 mm |

|

DH 630/5 |

5 mm |

1.5 mm |

11.3 mm |

13.5 kg/m2 |

800 - 1200 mm |

|

DH 800/5 |

6 mm |

2 mm |

12.8 mm |

16 kg/m2 |

1000 - 1200 mm |

|

Approximately |

|||||

Recommended mesh count for fabric reinforced conveyor belts

Based on the needs of different industries and material characteristics, the mesh count selection of fabric reinforced conveyor belts can refer to the following table:

|

Industry/application field |

Conveying materials |

Material particle size range |

Recommended mesh count (with screen or attached layer) |

Description and remarks |

|

Grain processing |

Corn, wheat flour, etc. |

≤ 1 mm (fine powder) |

60~120 mesh |

Need to prevent dust leakage, can be equipped with filter cloth or cover layer |

|

Feed industry |

Pellet feed, premix |

0.5~5 mm |

30~60 mesh |

Used for screening accuracy control, particle screening |

|

Chemical raw material transportation |

Urea, phosphate, etc. |

1~3 mm |

40~80 mesh |

Powder is easy to agglomerate, equipped with anti-blocking screen |

|

Cement/building materials |

Cement powder, lime powder |

10~150 μm |

80~200 mesh |

Prevent dust leakage, it is recommended to use a sealed conveying structure |

|

Mining/ore dressing |

Iron ore, coal powder |

2 mm~20 mm |

10~40 mesh |

used with vibrating screen |

|

Food/pharmaceutical industry |

starch, whey powder, etc. |

≤ 200μm |

100~300 mesh |

optional food-grade wear-resistant mesh or anti-static material |

Mesh selection instructions

Mesh definition: Mesh refers to the number of mesh holes per inch (25.4mm) in length. The higher the mesh, the smaller the mesh hole and the smoother the surface.

Low mesh (10-30 mesh): suitable for large particles and heavy-loaded materials, such as ore and coal.

Medium mesh (30-60 mesh): general type, suitable for powdery and granular materials, balancing strength and filterability.

High mesh (60-80 mesh): suitable for fine materials, such as food, medicine, and electronic components, requiring high cleanliness.

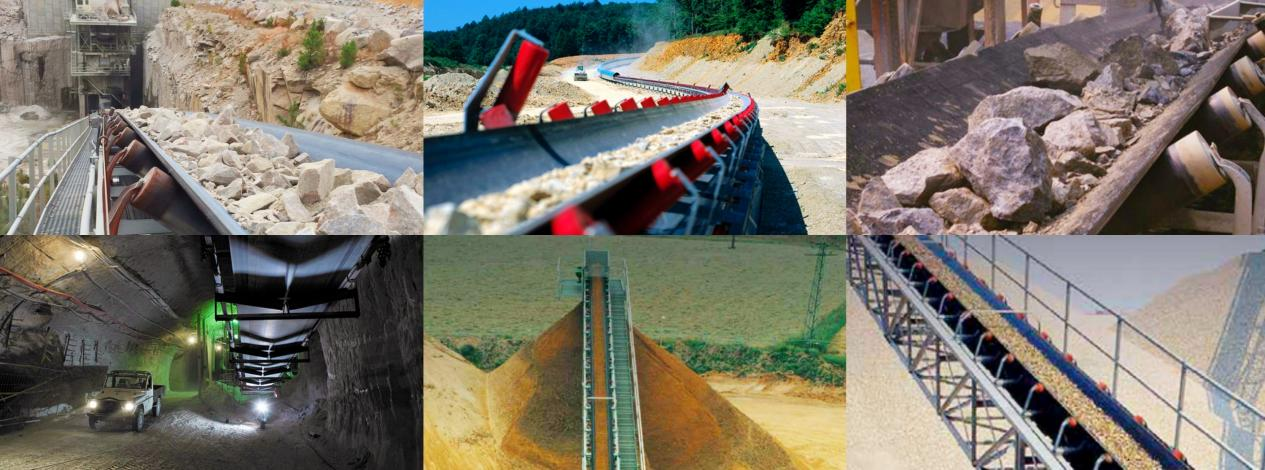

Application of fabric reinforced conveyor belts

Fabric reinforced conveyor belts are widely used in continuous conveying operations of bulk materials in many industries due to their reasonable structure, stable performance and strong adaptability.

Mining and ore processing: used for the transportation of materials such as coal, metal ore, sand and gravel, bearing heavy loads and long-distance transportation, commonly seen in open-pit mines and underground operations.

Cement and building materials industry: transporting raw materials (such as limestone and clinker) in cement plants and sand and gravel production lines, adapting to high temperature and abrasive environments.

Metallurgy and steel: used for transporting high-temperature or heavy materials such as iron ore, coke, and steel slag. Some high-temperature resistant fabric reinforced conveyor belts can withstand extreme conditions up to 800°C.

Agriculture and food processing: in the transportation of grains, feed, and fertilizers, fabric reinforced conveyor belts are widely used due to their durability and low maintenance costs, and are suitable for continuous production.

Logistics and warehousing: used for sorting, loading and unloading of goods, fabric reinforced conveyor belts with skirt or baffle design improve logistics efficiency, and are commonly seen in express delivery and large warehouses.

Food processing: food-grade fabric reinforced conveyor belts are suitable for food transportation due to their smooth surface and easy cleaning, such as bread, meat, vegetables and other processing lines.

Automobile and electronics manufacturing: conveying parts or finished products in the production line, supporting precise positioning and rapid transportation, and improving production efficiency.

Chemical and energy: used to convey chemical raw materials, coal, biomass, etc. Some special fabric reinforced conveyor belts have oil-resistant and corrosion-resistant properties.

Supplier of fabric reinforced conveyor belts

Xinxiang Dahan Vibration Machinery Co., Ltd. is a company specializing in the research, development, manufacturing and sales of material conveying and screening equipment. It provides various types of conveyor equipment to meet the needs of different material conveying. Dahan Machinery's fabric-reinforced conveyor belt products mainly include belt conveyors (suitable for conveying bulk materials such as powder, granules, and small blocks), large-angle belt conveyors (suitable for conveying materials with a large angle), telescopic belt conveyors (suitable for loading and unloading bulk materials), and PVC belt conveyors (suitable for food, medicine, chemical and other industries).

My whatsapp: +86 15236742901

e-mail: sale@xxdahan.com

If you have specific conveying needs or need to know more about Dahan Machinery's products, it is recommended to contact customer service or send an email or whatsapp to get detailed information.