Fire resistant conveyor belt

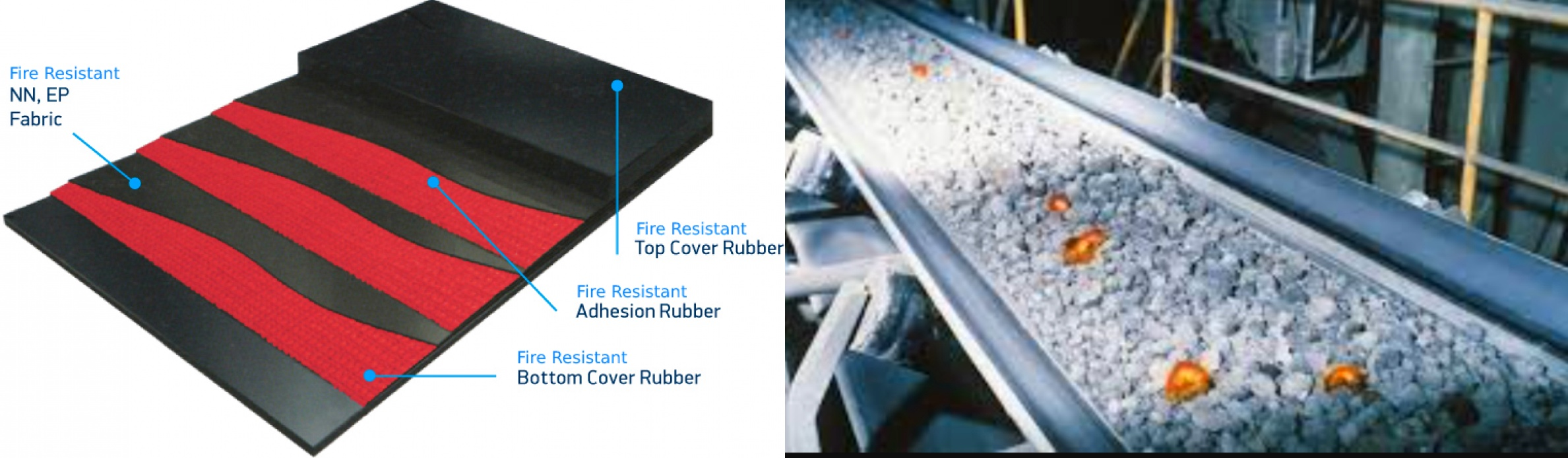

Fire resistant conveyor belt is a special conveyor belt designed for high temperature, flammable and corrosive environment. It can operate stably under extreme conditions to avoid fire or equipment damage. Its main feature is that it can maintain its performance and structural integrity in high temperature or flame environment to ensure the normal transportation of materials and production safety.

Product Introduction

Fire resistant conveyor belt is a rubber conveyor belt with excellent high temperature resistance and flame retardant properties, which is used to transport materials in high temperature environment or flammable environment. It can not only resist the burning of high temperature materials, but also delay combustion under high temperature generated by open flame or friction heat to ensure production safety.

What are the applicable materials for fire resistant conveyor belt?

Fire resistant conveyor belt is suitable for conveying specific materials in high temperature, flammable or high fire risk environment. It is designed to withstand high temperature, prevent combustion, and has flame retardant and antistatic properties.

Sintered ore, pelletized ore, hot ore, high-temperature steel billet, iron slag, steel slag, coke

Cement clinker, limestone, gypsum, fly ash, high-temperature sand and gravel

Coal, coal powder, coal slag, slag, waste slag ash, tar slag

High-temperature slag after incineration, combustible impurities in domestic garbage, thermal pollutants in industrial waste

High-temperature coal blocks, coal gangue, high-temperature ore, mineral materials after heat treatment

Granular fertilizers such as ammonium nitrate and urea, resin particles, high-temperature chemical reaction residues, flammable chemical powder raw materials

Video of fire resistant conveyor belt

What is the working principle of fire resistant conveyor belt

Fire resistant conveyor belt is driven by the motor through the reducer to drive the drive roller to rotate, and the conveyor belt relies on friction to run synchronously with the roller. The material is laid on the conveyor belt and is taken to the target position as the conveyor belt moves. The surface rubber is equipped with a heat-resistant and flame-retardant formula, which is not easy to age, burn or break even when in contact with high-temperature materials (such as 200°C clinker and steel slag).

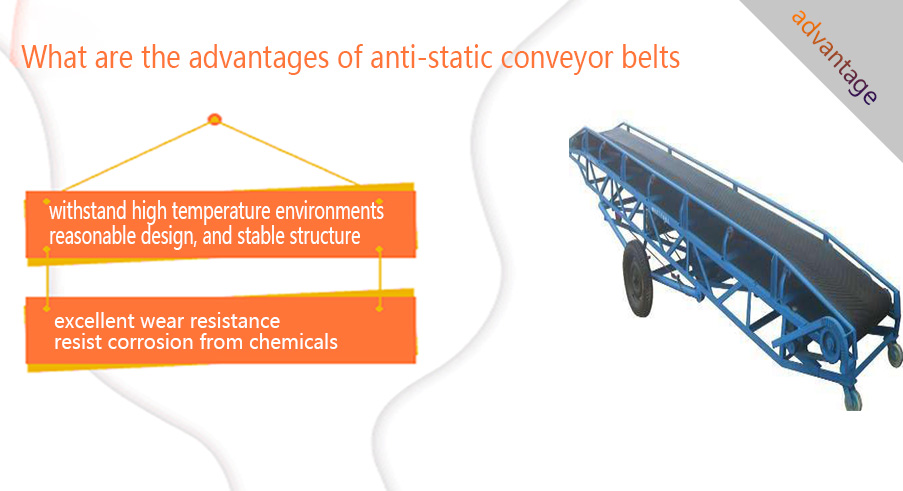

What are the benefits of a fire resistant conveyor belt?

Fire resistant conveyor belts are specially designed for flame retardant coatings and can withstand high temperature environments, usually 200℃-800℃

The conveyor belt has excellent tensile strength, reasonable design, and stable structure, and can operate safely under harsh working conditions such as high temperature and high load

The conveyor belt adopts special materials and processes, and has excellent wear resistance. The high wear resistance is designed to reduce the maintenance requirements of conveyors that are easily damaged by blast furnace flames

Fire resistant conveyor belt can resist corrosion from chemicals such as acids, alkalis, and salts, and is suitable for mining, thermal power plants, coal cleaning plants and other fields

Specifications of fire resistant conveyor belts

|

Cover Type |

Standards |

Minimum Tensile Strength (MPA) |

Minimum Elongation (%) |

Abrasion |

|

Fire resistant conveyor belt

|

SANS-F |

17 |

350 |

180 |

|

IS-1891(FR Grade) |

17 |

350 |

200 |

|

|

ISO-340(FR Grade) |

17 |

350 |

180 |

|

|

AS-F(FR Grade) |

14 |

300 |

200 |

|

|

AS-1332(FR Grade) |

14 |

300 |

200 |

|

|

DIN S Grade |

17 |

350 |

180 |

|

|

DIN K Grade |

17 |

400 |

200 |

|

|

MSHA-FR |

17 |

350 |

200 |

|

|

CAN/CSA (FR Grade) |

17 |

350 |

200 |

|

Cover Rubber Property |

||

|

Tensile Strength / MPA |

Elongation at break / % |

Abrasion / mm3 |

|

≥18 |

≥450 |

≤200 |

|

≥16 |

≥400 |

≤250 |

Applications of fire resistant conveyor belts

Due to its special materials and structural design, the fire resistant conveyor belt can operate stably in harsh environments such as high temperature and high heat radiation, so it has important applications in many industrial fields.

Coal conveying system: Coal is flammable and generates frictional heat during transportation, so flame retardant and fire resistant conveyor belts are used, especially in high-temperature areas such as boiler coal inlet. The slag of thermal power plants is high temperature and the particles are rough, which is a great test for the conveyor belt during transportation.

Metallurgy, steel conveying system: conveying high-temperature ore, coke, sintered ore, pelletized ore and other raw materials into blast furnaces, sintering machines and other equipment. These materials are usually at high temperatures and require high heat resistance of the conveyor belt. Convey high-temperature by-products such as steel slag and slag.

Mine conveying system: In some coal mines or metal mines, if there are materials with a high risk of spontaneous combustion, it may be necessary to use conveyor belts with certain flame retardant or fire resistant resistant properties to improve safety.

|

Steel plant |

Cement plant |

Glass plant |

Waste incineration plant |

|

High-temperature ore transportation in open-pit mines |

Mineral calcination production line |

Underground flame-retardant conveyor belts |

Glass manufacturing industry |

Price of fire resistant conveyor belt

The price of fire resistant conveyor belt varies greatly due to factors such as material, specification, and purpose. The following are factors that affect the price:

Material: Conveyor belts are made of a variety of materials, including rubber, PVC, Teflon, etc., and the prices of different materials vary greatly.

Specifications: The width, thickness, length and other specifications of the fire resistant conveyor belt are different, and the price will also vary. Generally speaking, the larger the specification, the higher the price.

Purpose: When fire resistant conveyor belts are used in different industries and scenarios, the performance requirements are different, so the price is also different. For example, conveyor belts used in harsh working conditions such as high temperature and heavy load are usually more expensive.

Customer cases of fire resistant conveyor belts

Fire resistant conveyor belt s have become important equipment in the field of high-temperature material transportation due to their excellent high-temperature resistance, wear resistance, and corrosion resistance. They are widely used in metallurgy, building materials, chemicals, electricity, mining and other industries.