Heat resistant conveyor belt

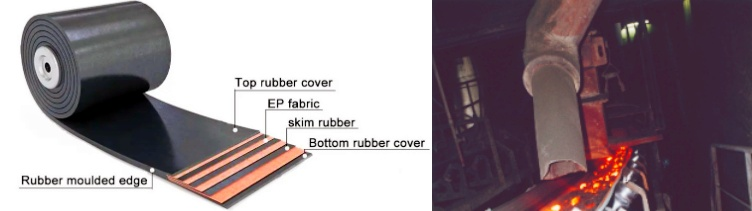

Heat resistant conveyor belt, whose outer cover is resistant to cracking and hardening. Durable and flexible even under severe working conditions and loads. Provides excellent performance even under extreme high temperature conditions.

Selling point:

Can reduce maintenance and downtime

Can withstand heat loads of 200°C to 300°C

Durable and flexible even under severe working conditions and loads.

Suitable for applications such as foundries, cement plants and glass manufacturingHeat resistant conveyor belt, whose outer cover is resistant to cracking and hardening.

Product description

Heat resistant conveyor belts are essential for industries involving high temperature operations. Heat resistant conveyor belts are designed for conveying materials that generate high temperatures during processing. Made of special materials, they can withstand high temperature environments, prevent performance degradation and maintain performance. These conveyor belts can convey materials such as clinker, sinter and pellets at temperatures up to 200°C or higher, and have excellent thermal stability and resistance to hot wear.

Grade description of heat resistant conveyor belts

Conveyor belts are usually divided into different grades according to the materials used for their cover layers and their specific performance characteristics. These grades determine the suitability of the conveyor belt for different applications, including its heat resistance, wear resistance and impact resistance.

|

Types |

M Grade (General Purpose) |

N Grade (Medium Heat Resistance) |

T Grade (High Heat Resistance) |

H Grade (Ultra-High Heat Resistance) |

|

Applicable Scenarios |

Transporting materials with moderate temperatures and abrasion |

Suitable for applications such as recycling plants where materials may be hot but not overheated |

Commonly used in foundries, cement plants and steel plants |

Suitable for the most demanding applications, such as glass manufacturing and continuous casting operations |

|

Withstands |

Intermittent moderately high temperatures |

Withstands temperatures up to 100°C |

Withstands temperatures up to 150°C |

Withstands temperatures up to 200°C and even higher |

|

Features |

Flexibility and durability |

High heat resistance |

Withstands extreme heat |

Durability and protection against heat damage |

Classification of Heat resistant conveyor belts

Temperature resistance grade is an important indicator of heat-resistant conveyor belts. These grades indicate the maximum temperature that the conveyor belt can withstand while maintaining its performance and integrity. Classification by temperature grade category:

Low temperature conveyor belt: This type of conveyor belt can withstand temperatures up to 200°F. For applications where heat levels are low, such as light industrial manufacturing processes.

Medium Heat Belts: Withstands temperatures up to 400°F, these belts are used in industries such as baking where ovens and dryers are common.

High Temperature Belts: Withstands temperatures up to 600°F and are used in heavy industries such as metalworking, glassmaking, and foundries.

Video of heat resistant conveyor belt

Application range of high-temperature materials

|

Material |

Temperature Range (°C) |

Belt Surface Temperature (°C) |

|

High-Temperature Alloys |

|

|

|

Stainless Steel |

900 - 1200 |

800 - 1000 |

|

Inconel |

1000 - 1400 |

900 - 1200 |

|

Tungsten |

1500 - 3400 |

1200 - 1500 |

|

Molybdenum |

1200 - 2600 |

1100 - 1400 |

|

Refractory Materials |

|

|

|

Graphite |

2000 - 3000 |

1500 - 2000 |

|

Silicon Carbide |

1400 - 1600 |

1200 - 1400 |

|

Aluminum Oxide (Alumina) |

1400 - 1900 |

1200 - 1500 |

|

Zirconium |

900 - 1500 |

800 - 1100 |

|

Tantalum |

1400 - 3000 |

1300 - 1700 |

These temperature ranges indicate the maximum operating temperature of each material, making it suitable for use in high-temperature environments such as mining, aerospace, and industrial furnaces.

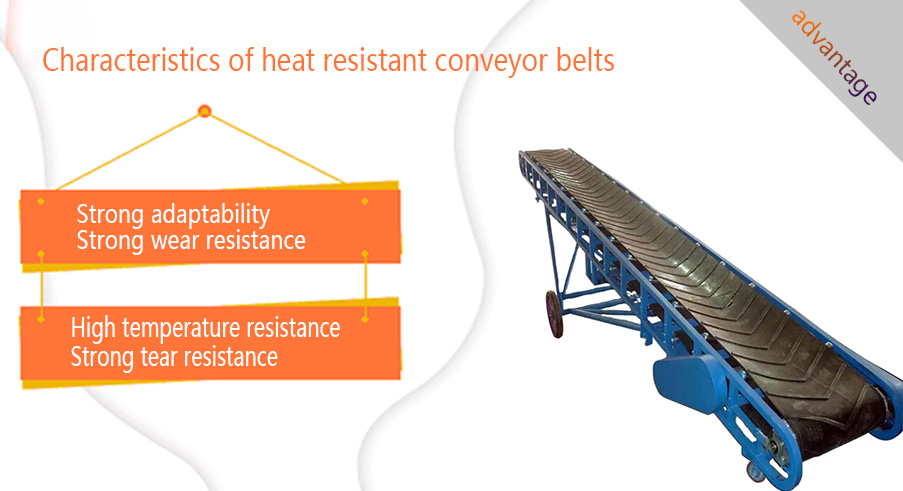

Characteristics of heat resistant conveyor belts

Strong adaptability: These belts can transport any hot material, whether it is hot food or fertilizer, sintered ore, cement, soda ash, coke, slag, etc.

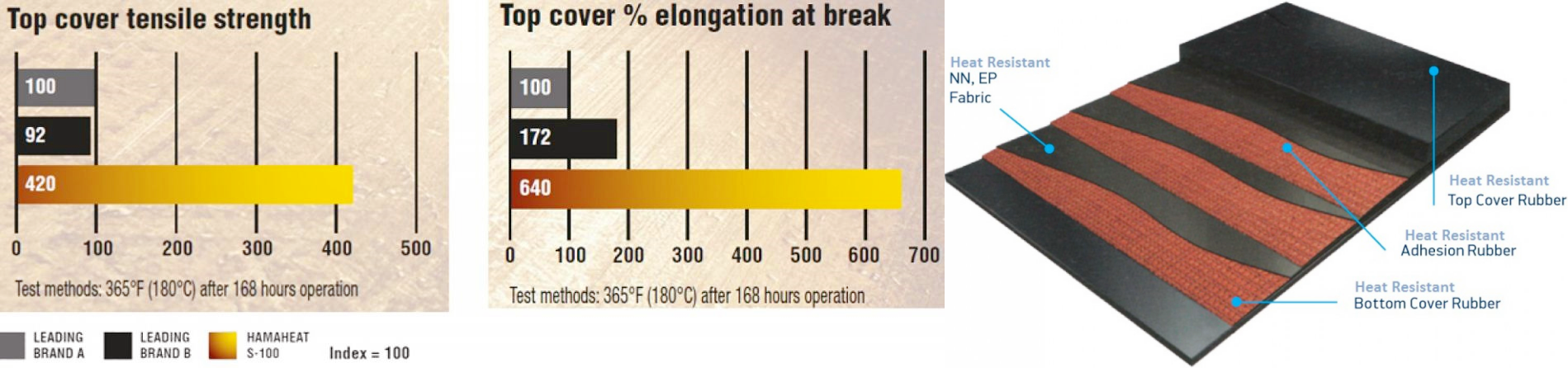

Strong wear resistance: Special rubber is injected into the heat resistant conveyor belt to avoid severe wear and extend the service life of the product. In addition, this conveyor belt also has high heat resistance.

High temperature resistance: Depending on the material, the temperature resistance range covers 150°C to 800°C, the ordinary heat resistant rubber range covers ≤150°C, the silicone range covers ≤250°C, and the ceramic fiber range covers ≤800°C. The physical properties remain stable at high temperatures without softening or brittle cracking.

Strong tear resistance: For sharp materials that may be encountered during the conveying process or tearing forces caused by changes in conveying angles, heat resistant conveyor belts have good tear resistance, reducing the risk of tearing and damage to the conveyor belt.

Technical specifications of heat resistant conveyor belts

|

Model |

heat-resistant test temperature |

maximum short-term operating temperature |

cover material |

core material |

applicable scenarios |

|

Type I |

≤100℃ |

150℃ |

styrene-butadiene rubber , ethylene-propylene rubber |

polyester-cotton canvas or polyester canvas |

conveying materials below 100℃, such as cement and fertilizer |

|

Type II |

≤125℃ |

170℃ |

styrene-butadiene rubber , ethylene-propylene rubber |

polyester-cotton canvas or polyester canvas |

conveying materials below 125℃, such as coke and sintered ore |

|

Type III |

≤150℃ |

200℃ |

ethylene-propylene rubber , butyl rubber |

polyester canvas (EP100-EP500) |

conveying materials below 150℃, such as slag and hot castings |

|

Type IV |

≤175℃ |

400℃ |

ethylene-propylene rubber , butyl rubber |

polyester canvas (EP100-EP500) |

Convey high-temperature materials below 175℃, such as hot coke |

|

V type |

≤240℃ |

600℃ |

EPDM or special heat-resistant rubber |

High-temperature canvas or steel mesh |

Convey ultra-high-temperature materials below 240℃, such as high-temperature castings |

Precautions:

The running speed of the heat resistant conveyor belt should generally not exceed 2.5 m/s.

Avoid the rollers being covered by materials to prevent leakage from being stuck between the rollers and the belt.

When storing, the warehouse temperature should be kept at 18-40℃ and the relative humidity at 50-80%. Avoid direct sunlight and contact with acids, alkalis, and oils.

Application of heat resistant conveyor belts

The company uses the highest quality raw materials to produce products that serve all walks of life. For example, fields such as. Heat resistant conveyor belts are conveyor belts specially designed for conveying materials in high temperature environments. They are widely used in cement industry, steel industry, fertilizer, metallurgy, building materials, chemical industry, food processing, electricity, waste incineration, coking plants, foundries, underwater ash removal, waste utilization, glass factories and other industries.

Customer cases of heat resistant conveyor belts

|

|

|

|

|

|

Blast furnace ironmaking in steel plants |

Clinker transportation in cement plants |

High-temperature material transportation in glass factories |

Waste incineration |

Heat resistant conveyor belt Price

The price of heat resistant conveyor belts is affected by many factors, including material, specification, temperature resistance grade, brand and market supply and demand, so the price range is wide.

Ordinary heat resistant conveyor belt (temperature resistance 100-150℃): The price is usually around RMB 50-150 per square meter, depending on the thickness, width and number of layers.

High-temperature resistant conveyor belt (such as EPDM rubber, silicone or Teflon material, temperature resistance 200-800℃): The price is higher, which may be RMB 150-500 per square meter or even higher, especially for food grade or special industrial conveyor belts.

If you need a customized or special purpose conveyor belt (such as burn-resistant, flame-retardant or acid-alkali resistant), you can contact our customer service by email and quote according to specific needs.