High speed belt conveyor

Continuous conveying equipment that conveys materials at high speed, widely used in occasions with high requirements for conveying efficiency and conveying speed.

Conveying speed: 2.0-10.0 m/s (customizable)

High belt speed: usually belt speed ≥4m/s, up to 8-10m/s

Bulk density: less than 1.67 tons/cubic meter, suitable for powder, granular, and small block materials

What is a high speed belt conveyor?

High speed belt conveyor refers to a belt conveying system with a running speed usually exceeding 2.5m/s. Compared with ordinary belt conveyors (running speed 0.8~2.5m/s), it has higher conveying efficiency and beat control capabilities. Its main structures include: drive device, conveyor belt, roller group, tensioning device, bracket, control system, etc.

Working principle of high speed belt conveyor

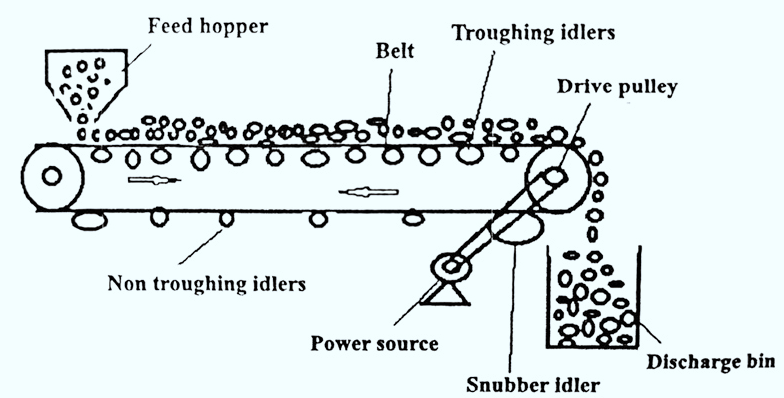

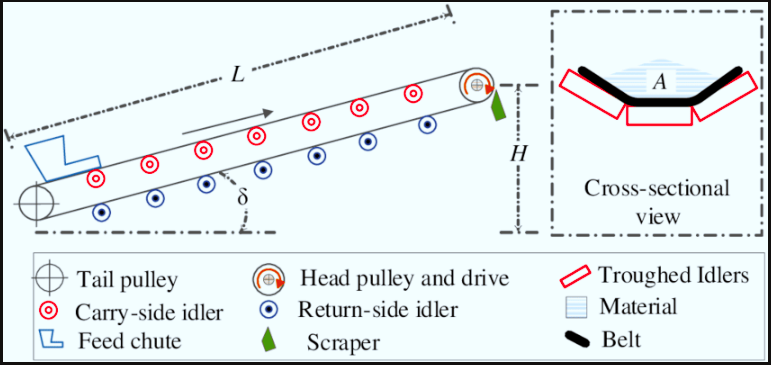

The working principle of belt conveyor is mainly based on friction transmission. The drive device drives the roller to rotate, and the roller drives the conveyor belt to move through the friction between the roller and the conveyor belt, thereby realizing the conveying of materials. In high speed operation, proper belt tension is the key to ensure that the belt fits tightly with the roller and avoids slipping.

The friction between the belt and the roller is the basis of transportation, and a sufficient friction coefficient needs to be maintained. The transmission speed needs to be adjusted to a suitable range, and real-time monitoring and adjustment are required to ensure stable and efficient operation. Wear or aging of moving parts such as transmission rollers and rollers will affect the efficiency and stability of transportation, and regular inspection and maintenance are required.

Features of high speed belt conveyors

Fast conveying speed: The common conveying speed range is 2.5~5.0m/s, and some special models can even reach more than 10m/s, which is suitable for fast handling of large quantities of materials or fast sorting of single pieces.

Good stability: Equipped with an automatic deviation correction system, it can correct the deviation of the conveyor belt in time to ensure the smooth operation of the conveyor belt; at the same time, the use of high-quality components and advanced manufacturing processes reduces the probability of failure and improves the reliability of the equipment.

Large conveying capacity: can handle loose materials (such as coal, gravel, sand, etc.) and finished items, with a conveying capacity of more than 1,500 tons per hour.

Technical parameters of high speed belt conveyor

|

Model |

Bandwidth (mm) |

Conveying length (m) |

Conveying speed (m/s) |

Conveying capacity (t/h) |

Applicable scenarios |

|

DHPD-500 |

500 |

20 |

3.0 |

≤100 |

Express parcel delivery, light industrial products |

|

DHPD-650 |

650 |

30 |

4.0 |

≤200 |

Automated warehousing and sorting system |

|

DHPD-800 |

800 |

5 0 |

5.0 |

≤400 |

High-speed transportation of building materials and sand and gravel |

|

DHPD-1000 |

1000 |

60 |

4.5 |

≤600 |

Port loading and unloading, metallurgical mines |

|

DHPD-1200 |

1200 |

80 |

4.5 |

≥800 |

Bulk material conveying, high-load system |

Structural composition of high speed belt conveyor

High speed belt conveyor usually consists of the following main parts:

Conveyor belt: This is the part that directly contacts and carries the material. According to the different characteristics of the material (such as weight, particle size, temperature, etc.), conveyor belts of different materials and types can be selected.

Drive device: It includes components such as motors and reducers to provide power for the conveyor. In order to achieve high speed operation, a specially designed high-efficiency drive system is usually used.

Roller: It is divided into drive roller and redirection roller. The drive roller is connected to the drive device and is the power source for the movement of the conveyor belt; the redirection roller is used to change the direction of the conveyor belt.

The tensioning device ensures that the conveyor belt has proper tension to prevent slipping and deviation from the track. The support structure supports the framework of the entire conveyor system to ensure its stability and firmness.

What can high speed belt conveyors be used for?

High speed belt conveyors are widely used in industries with high requirements for conveying efficiency and automation, especially in logistics sorting centers, airport baggage handling systems, automated warehousing, electronic manufacturing, port loading and unloading, and large factory assembly lines.

For example, in e-commerce logistics centers, parcels need to be put into storage, scanned, weighed and sorted in a short time. High speed belt conveyors can realize continuous conveying of parcels at a speed of 4 to 5 meters per second, improving the overall circulation efficiency; at airports, baggage is transferred from the check-in counter to security inspection, and then to the boarding gate or baggage carousel. The whole process relies on high speed conveying systems to achieve precise docking; at ports and bulk material yards, high speed belt conveyors are used for rapid loading and unloading and stacking of coal and ore to improve the handling capacity of bulk materials.

What is the maximum conveying speed of high speed belt conveyors?

The maximum conveying speed of high speed belt conveyors can vary greatly depending on the specific design and application scenarios. Generally, the speed of general belt conveyors ranges from 0.8 to 4 m/s, while some belt conveyors specially designed for high speed operation can reach speeds of 3.0 to 5.0 m/s, which are suitable for large-scale, long-distance material transportation, such as port terminals, power plants and other scenarios.

However, in some specific applications, the speed of belt conveyors may be higher through special design and material selection. For example, the effective bandwidth of high speed belt conveyors produced by Dahan Machinery Manufacturing Co., Ltd. is 300-1500mm, and the belt speed range is 0.8-4.0m/s. Please note that the maximum speed in actual applications also needs to consider safety and the stability of material transportation.