Sand and gravel conveyor belt

Sand and gravel conveyor belt is a conveying system specially designed for efficient conveying of loose materials such as sand and gravel. It is usually used in conjunction with sand making equipment such as vibrating feeder, crusher, vibrating screen sand machine, etc. to form a complete sand and gravel production line to realize the automation of sand and gravel production.

Belt width: 400-1000mm

Conveying capacity: 70-300m³/h

Conveying length: 10-15 meters

Conveying speed: 1.25-2.0m/s

Application scenarios: widely used in mining, construction, ports, metallurgy, chemical industry and other fields.

Product introduction

Sand and gravel conveyor belt is a conveying equipment used to convey bulk materials such as sand and gravel. It is widely used in mines, building materials, concrete mixing plants, port terminals and other places. Its main function is to efficiently and continuously transport sand and gravel from one location to another, improve transportation efficiency and reduce labor costs.

Different types of sand and gravel conveyor belts

Different types of sand and gravel conveyor belts are designed to meet the abrasiveness and different operating needs of the aggregate industry. Gravel conveyor belts can be divided into the following types according to the conveying angle and function:

According to the conveying angle:

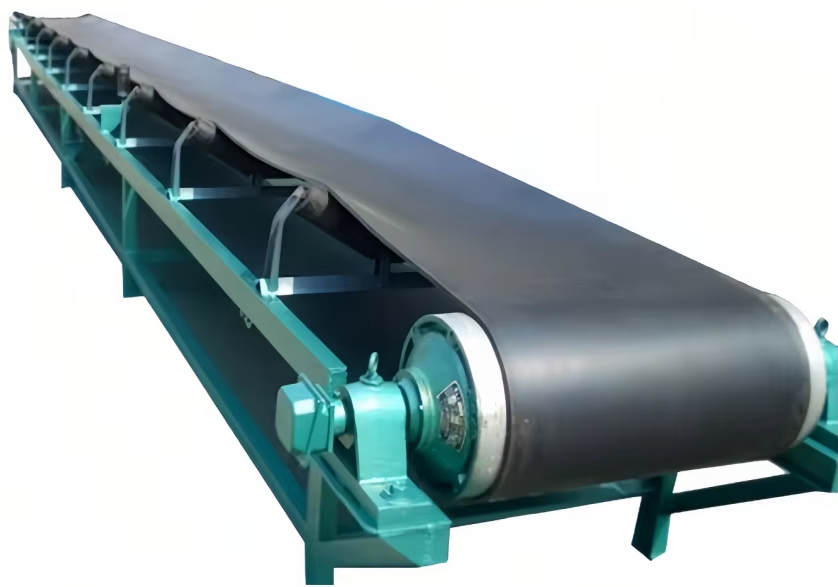

Horizontal sand and gravel conveyor belt:

Description: Flat belt runs on pulleys and is supported by rollers or sliders.

Use: Suitable for horizontal or slightly inclined transportation of sand, gravel and other bulk materials and various processing and storage stages.

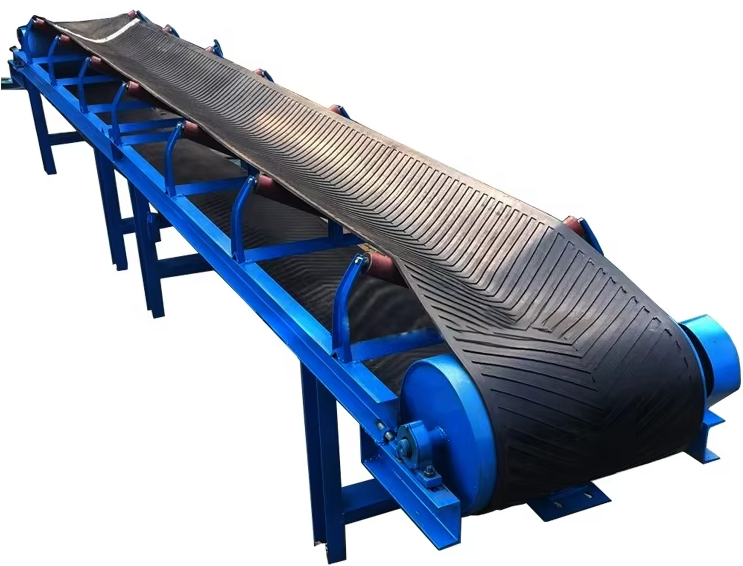

Inclined sand and gravel conveyor belt:

Description: Designed to transport materials at a certain angle (15° to 30°, sometimes up to 60° with special designs).

Application: Commonly used in mining, construction sites at different heights, and transporting materials from the ground to the yard or processing equipment.

Based on function/mobility:

Fixed sand and gravel conveyor belt:

Description: Installed in a fixed position for long-term or continuous conveying tasks.

Use: Suitable for fixed production lines, mines, aggregate processing plants with consistent material flow paths.

Mobile sand and gravel conveyor belt:

Description: Designed for easy transportation and temporary use at different locations within the site.

Application: Suitable for construction sites, temporary settings, and situations where the conveying path needs to be changed frequently.

Sidewall sand and gravel conveyor belt:

Description: The edge of the belt is equipped with corrugated sidewalls to increase the load-bearing capacity under high slopes and prevent the spillage of loose materials such as sand and gravel.

Use: Suitable for material transportation with limited space and large inclination angles.

Video of sand and gravel conveyor belt

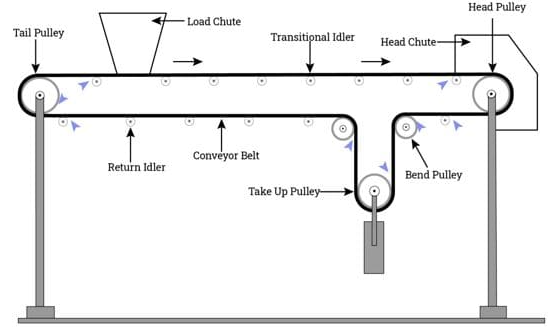

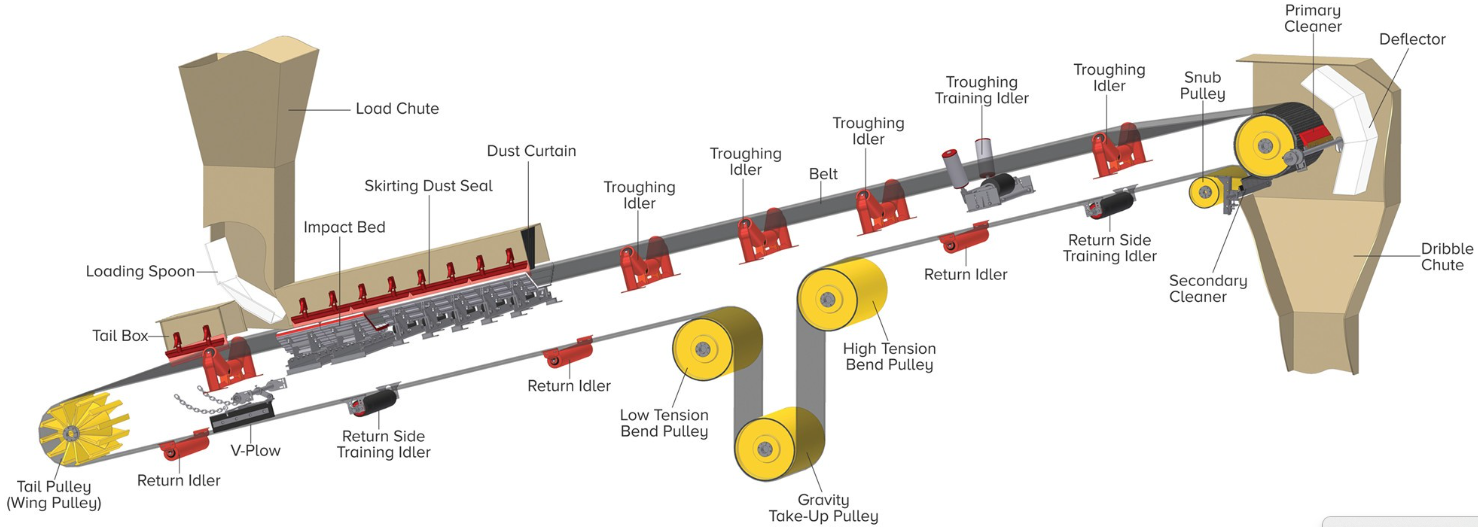

Structure of sand and gravel conveyor belt

The main structure of the sand and gravel conveyor belt includes:

Drive roller: The motor drives the belt to move.

Belt: As the material of the load-bearing and traction components, it has high strength and good wear resistance.

Idle roller: Installed on the frame, it is used to support the belt and the materials on the belt to prevent the materials from falling or piling up.

Driving device: including motor, reducer, brake, etc., to provide power for the driving roller.

Unloading device: located at the end or specific position of the belt conveyor, used to unload materials.

What is the working principle of the sand and gravel conveyor belt?

The working principle of sand and gravel conveyor belt is to transport the gravel materials from the starting point to the end point through a continuously circulating belt body and mechanical drive. Its core is a closed ring belt body.

Driving device start: The motor transmits power to the driving roller through the reducer, and the driving roller drives the belt to move by the friction with the inner side of the conveyor belt.

Circulating operation of sand and gravel conveyor belt: The sand and gravel conveyor belt forms a closed ring structure around the driving roller and the redirecting roller, and continues to circulate under the support of the roller.

Material loading and transportation: The gravel falls evenly from the feed port onto the sand and gravel conveyor belt and moves forward with the belt.

Material unloading: At the end of the sand and gravel conveyor belt, the gravel is separated from the belt due to inertia or the action of the discharger to complete the conveying.

What are the advantages of the sand and gravel conveyor belt?

Dealing with high loads and belt breakage risks

Sand and gravel production lines may face overloads or sudden impacts, causing the conveyor belt to tear or break. Install overload sensors and emergency stop devices to automatically stop when overloaded to protect the sand and gravel conveyor belt.

Solve material accumulation and spillage

Sand and gravel are prone to accumulation and spillage at the drop point or transition point, causing waste and equipment blockage. Install buffer rollers or buffer beds at the drop point to slow down the impact of sand and gravel materials and prevent accumulation.

Prevent belt slippage

On inclined conveyors or when carrying heavy objects, the belt may slip on the drive pulley, which may damage the belt. Maintaining the correct belt tension ensures full contact with the drive pulley without excessive tension on the belt.

Solve uneven load problems

If the material is not evenly loaded onto the belt, it will cause belt misalignment and uneven wear. Using well-designed chutes and feeders can ensure that the material is more evenly distributed on the sand and gravel conveyor belt.

Specifications of sand and gravel conveyor belts

|

Belt width(mm) |

Conveying length(m) Power(kw) |

Conveying speed(m/s) |

Conveying amount(t/h) |

||

|

DH400 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

30-60 |

|

3 |

3-4 |

4-7.5 |

|||

|

DH500 |

≤10 |

12-15 |

15-30 |

40-80 |

|

|

3 |

4-5.5 |

5.5-7.5 |

|||

|

DH650 |

≤10 |

12-15 |

15-30 |

80-120 |

|

|

4 |

7.5 |

7.5-11 |

|||

|

DH800 |

≤10 |

12-15 |

15-30 |

120-200 |

|

|

4 |

7.5 |

7.5-15 |

|||

|

DH1000 |

≤10 |

10-20 |

20-40 |

200-320 |

|

|

5.5 |

7.5-11 |

11-22 |

|||

|

DH1200 |

≤10 |

10-20 |

20-40 |

290-480 |

|

|

7.5 |

7.5-15 |

15-30 |

|||

|

DH1400 |

≤10 |

10-20 |

<20-40 |

400-680 |

|

|

11 |

>15-22 |

22-45 |

|||

What are the applications of sand and gravel conveyor belts?

Sand and gravel conveyor belts are widely used in gravel production lines, concrete mixing plants, mining production lines, gravel plant production lines, construction waste treatment production lines, port terminals, construction sites, etc., and can meet the needs of various production scales of machine-made sand production lines. Sand and gravel conveyor belts are widely used in industrial scenarios that require efficient and continuous transportation of sand and gravel to improve production efficiency and automation levels.

Sand making equipment production system

Sand and gravel conveyor belts usually form a complete sand making production line with sand making equipment. The system equipment mainly includes vibrating feeders, crushing equipment, sand washing machines, belt conveyors, bucket elevators, sand screening machines, etc. The gravel conveying system can be customized according to the actual production needs of the gravel plant. It can be transported by a single machine, or it can be composed of multiple units or other conveying equipment to form a horizontal or inclined conveying system to meet the needs of different layouts of operation lines.

Sand and gravel conveyor belt manufacturer

Dahan Vibration Machinery Co., Ltd. is a manufacturer of gravel conveyor belts. Its main products include belt conveyors, mobile conveyors and high-angle conveyors, which are suitable for gravel production lines, mines, concrete mixing plants and other scenarios.

Diversified design: Provide oil-resistant, acid-resistant and alkali-resistant rubber conveyor belts with a belt speed range of 1.3-2.0m/s

Efficient support: Equipped with self-aligning rollers and buffer rollers to prevent deviation and reduce material impact

Modular structure: Supports horizontal, inclined or mobile layout to adapt to different working conditions

My whatsapp: +86 15236742901, e-mail: sale@xxdahan.com

If you need more specific models (such as bandwidth, length), quotes or technical parameters, you can visit Dahan's official website (www.xxpidaiji.com) or contact the manufacturer directly to obtain customized solutions.