gravel belt conveyor is a continuous conveying device used to transport bulk aggregates such as gravel. It can handle situations where gravel is highly abrasive, has many sharp edges, and is dense. In sand and gravel plants, construction sites, or mines, it is generally used between crushing, screening, and storage processes, smoothly transferring materials from one stage to the next, allowing for continuous operation and reducing manual handling.

Gravel belt conveyors have a belt width of approximately 400 to 1200 millimeters, with conveying capacities ranging from 70 to 1000 tons per hour. Under normal circumstances, the conveying distance is 10 to 50 meters, but if connected in sections, it can exceed 200 meters. The inclination angle is generally no more than 18°, but with the addition of deep grooves or sidewalls, it can reach 25°–35°. The belt speed is approximately 1.25 to 2.5 meters per second; the speed will be reduced slightly for larger particles or those containing more powder. It ensures smooth material flow, is simple to operate, and requires minimal maintenance and adjustment.

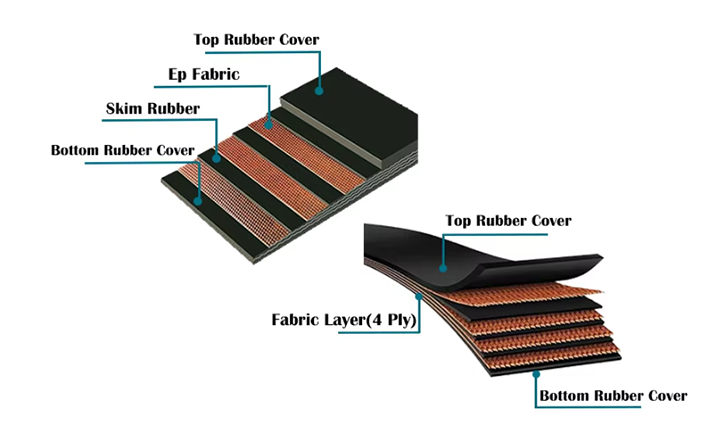

A gravel belt conveyor consists of a drive unit, rollers, idlers, a frame, a tensioning device, a cleaner, and a conveyor belt. The conveyor belt is a layered fabric belt with wear-resistant rubber layers on both sides, typically 3 to 8 millimeters thick, depending on wear conditions. This directly resists the friction and abrasion of gravel, extending the belt's lifespan. During operation, rollers and idlers support and guide the conveyor belt, the tensioning device ensures the belt doesn't loosen or deviate, and the cleaner removes gravel from the belt surface. Smooth operation of the entire system relies on the coordinated action of all components.

The function of a gravel belt conveyor is to continuously transport gravel, seamlessly connecting crushing, screening, storage, and loading processes, replacing intermittent transportation, and reducing manual handling and energy consumption. With deep-groove idlers, sidewalls, or partitions, it can increase the inclination angle and save space. Combined with dust covers, sealed chutes, and high-efficiency cleaners, it can control dust and material spillage, making operations cleaner and neater. Multiple conveyors can be used in series or parallel, or arranged horizontally or at an incline, adapting to more complex production processes. Some models can also unload in reverse or at multiple locations in the middle, making material yard scheduling more flexible. The transport route can be adjusted according to needs, not limited by fixed layouts, and easier to operate.

The price of a gravel belt conveyor varies depending on the model and working conditions. Small mobile models have a belt width of 500 to 650 mm and a length of approximately 10 to 15 meters, priced at around $1,400 to $2,400 per set. Medium-sized stationary models have a belt width of 650 to 800 mm and a length of 20 to 30 meters, with a drive and idlers, priced at approximately $2,600 to $4,500 per set. Prices may increase depending on the usage environment. For explosion-proof mining applications, the price increase is approximately 30% to 50%; for corrosion-resistant models used in coastal or chemical environments, the increase is 20% to 40%; for long-distance conveying exceeding 50 meters or steep inclines, the price may range from $5,000 to $9,000 per set, depending on the design and configuration.

Gravel belt conveyor manufacturers each have their own strengths. Some manufacturers' products are suitable for long-distance conveying and can be arranged on curves, making them suitable for large aggregate bases and ports; others focus on high wear resistance and high impact design, performing excellently when used in conjunction with crushing plants. Dahan Machinery's models can adapt to small, medium, and large stockyards and manufactured sand production lines, with a temperature range from -20℃ to 40℃. They also offer ultra-thick wear-resistant belt models for high-wear conditions, boasting long service life and good cost-effectiveness.

Gravel belt conveyors are used in sand and gravel quarries, mines, concrete mixing plants, construction sites, port bulk cargo terminals, and solid waste recycling aggregate lines. In stockyards, it is typically used to connect crushing and screening lines and to complete stockpiling or loading; in mines, it can be used for underground or open-pit aggregate transportation; in mixing plants and construction sites, it is used for raw material intake and finished product discharge; in ports, it is responsible for ship-to-shore loading and unloading and stockpile material transfer. Gravel belt conveyors facilitate smoother operations through continuous conveying, while reducing labor and losses. They are a commonly used conveying system that provides stable, safe, and supportive aggregate production.