Agricultural belt conveyor

Agricultural belt conveyor is a continuous material conveying equipment widely used in the field of agricultural production. It is mainly used to convey bulk or packaged materials such as grain, fertilizer, crops, feed, fruits and vegetables.

Conveying capacity: 50-200 tons/hour for bulk grain, 1200 bags/hour for packaged grain

Belt width: common 550mm, 650mm, 800mm

Product description

Agricultural belt conveyor is a continuous conveying equipment used in all aspects of agricultural production, and plays an important role in modern agriculture. It is mainly composed of conveyor belts, drive rollers, rollers, racks and other components. The belt is driven by the drive device to realize horizontal, inclined or combined transportation of materials.

The advantages of this equipment are significant. On the one hand, it can operate efficiently and continuously, and can handle dozens of tons of materials per hour, which is several times more efficient than manual handling. It also runs smoothly and has a low damage rate to easily broken agricultural products (such as fruits and fresh eggs); on the other hand, it has a wide range of applications, and can transport powdered fertilizers, granular grains, blocky root vegetables, and even bagged materials. By adding devices such as sidewalls and protective covers, it can also handle materials with different characteristics.

Application of belt conveyors in the agricultural field

Belt conveyors are widely used in the agricultural field, mainly for the transportation, loading and unloading and stacking of materials such as grain, feed, fertilizer, fruits and vegetables.

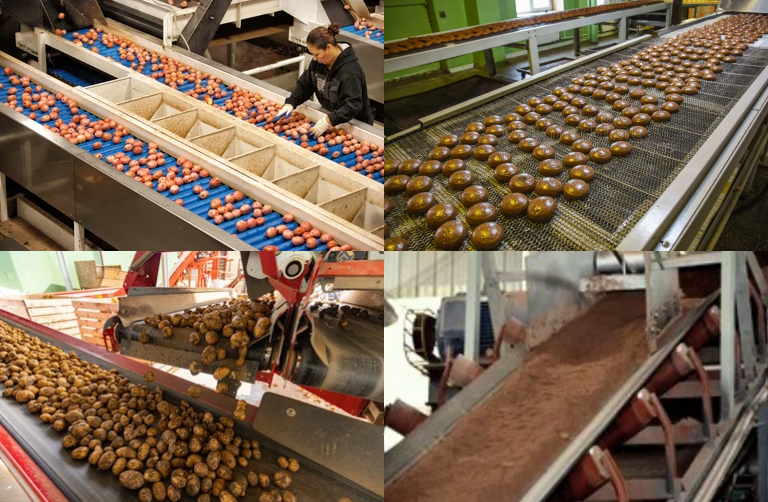

During the harvest season of grain crops such as rice, wheat, and corn, belt conveyors can be used for temporary transportation in the fields to quickly transport the harvested grain to transport vehicles or storage locations. In fruit and vegetable processing companies, belt conveyors are often used in the primary processing of crops such as tomatoes, potatoes, onions, and apples, such as from cleaning equipment to grading equipment, from grading areas to packaging areas, etc.

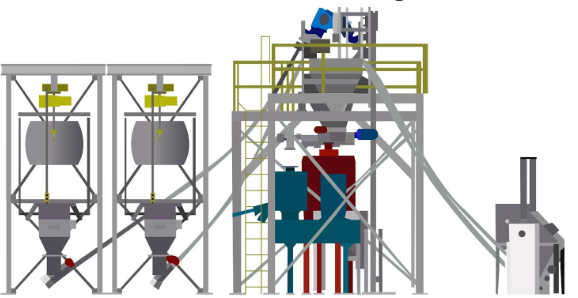

In feed mills and farms, belt conveyors can be used for feeding and conveying raw materials, transferring materials in proportioning systems, and packaging and conveying finished products. In scenarios such as livestock and poultry manure treatment, crop straw recycling, and farm organic fertilizer production, belt conveyors are used to transfer waste or send the mixture to crushers, fermentation tanks, composting machines, and other equipment for subsequent processing and resource utilization.

Applicable materials for belt conveyors

Belt conveyors are widely used continuous conveying equipment, and their applicable material types are very rich, almost covering various forms of materials such as solid particles, powders, blocks, and packaged materials. Granular materials are one of the most common conveying objects for belt conveyors, and usually have a certain fluidity, which is convenient for continuous conveying. For example, wheat, pellet feed, urea, iron ore particles, lime particles, etc.; powder materials are usually light and easy to generate dust, but belt conveyors can achieve effective transportation through sealing structures or slow-angle conveyor belts, such as cement, clinker powder, etc.; block materials are generally large in volume and heavy in weight, and require high wear resistance of the conveyor belt, such as coal blocks and coke blocks.

Belt conveyors are also widely used in the conveying production lines of various packaged items or finished products, especially in warehousing, sorting, express delivery, e-commerce and other industries, such as bagged fertilizers, grain, food packaged in cartons, etc.

Classification of agricultural belt conveyors

Mobile belt conveyor: equipped with walking wheels, it can be easily moved to different locations for operation, and the conveying angle can also be adjusted according to actual needs. It is suitable for places where the loading and unloading locations are frequently changed, such as farms, grain depots, ports, etc., for short-distance transportation and loading and unloading of bulk materials or finished items.

Fixed belt conveyor: installed in a fixed position, the conveying line is relatively fixed, usually used in large-scale agricultural production sites, such as grain storage warehouses and agricultural product processing plants in large farms, which can achieve long-term, continuous and stable material transportation.

Telescopic belt conveyor: with a retractable frame and conveyor belt, it can adjust the conveying distance according to needs, and can change the conveying length at will within a certain range. It is suitable for occasions where the conveying distance needs to be flexibly adjusted, such as in orchards, the conveyor length can be adjusted according to the distribution and picking position of fruit trees.

Large-angle belt conveyor: It uses special sidewalls or patterned conveyor belts to transport materials at a large angle. It can be used in agricultural production environments with complex terrain or limited space, such as material lifting in mountain orchards and crop transportation between terraces, which can effectively save space and floor space.

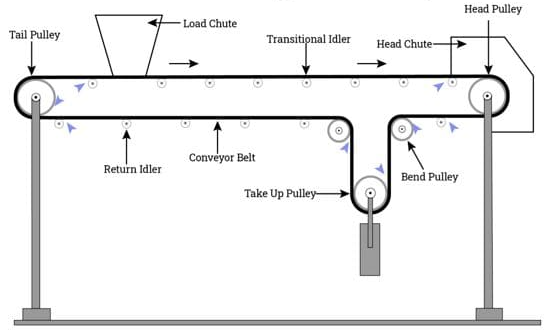

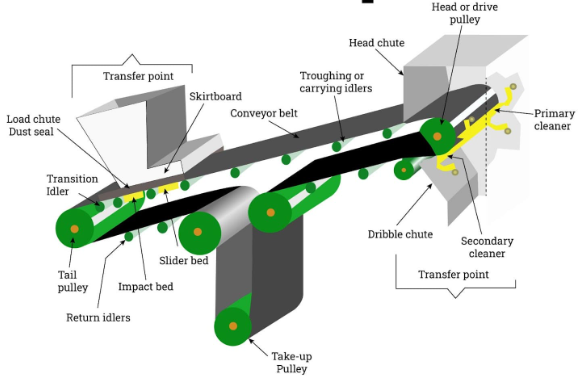

Structural composition of agricultural belt conveyor

Agricultural belt conveyor is mainly composed of conveyor belt, drive roller, redirecting roller, roller, frame, tensioning device, drive device, etc. Among them, the conveyor belt is the key component for carrying and conveying materials; the drive roller provides power to drive the conveyor belt to operate; the redirecting roller is used to change the running direction of the conveyor belt; the roller supports the conveyor belt and materials to reduce the running resistance of the conveyor belt; the frame plays the role of supporting and fixing various components; the tensioning device ensures that the conveyor belt has sufficient tension to prevent slipping; the drive device usually includes an electric motor, a reducer, etc., to provide power for the conveyor.

What are the advantages of agricultural belt conveyor

Continuous conveying: Agricultural belt conveyor adopts continuous conveying, which can stably and continuously transport a large amount of materials, and is suitable for large-scale centralized processing of grain, feed or fruits and vegetables. Small impact and low vibration during operation, especially suitable for occasions where material integrity needs to be protected (such as fruit and vegetable sorting lines, seed transportation, etc.).

High efficiency and low loss: Smooth operation reduces grain wear and breakage, reduces loss rate, and avoids the impact of external environment (such as moisture, pollution) on material quality. Compared with screw conveyors, belt conveyors can better maintain the integrity of grains.

Wide adaptability and diverse applications: It can be configured with accessories such as lifting baffles and skirts to adapt to different material properties (such as particle size, humidity), and supports conveyor belts made of various materials such as rubber, silicone, and PVC. Agricultural belt conveyors can adapt to a variety of agricultural materials, whether it is bulk soil, grains, fertilizers, or irregularly shaped fruits and vegetables, or even bagged products. By replacing different types of conveyor belts (such as flat belts, belts with baffles, and grooved belts) and adjusting the inclination angle, it can meet various complex conveying needs. Mobile belt conveyors can be flexibly deployed to different field or warehouse operation scenarios.

Technical parameters of agricultural belt conveyor

|

Model |

Belt width (mm) |

Conveying length (m) |

Conveying capacity (t/h) |

Motor power (kW) |

Conveyor belt speed (m/s) |

|

DY500 |

500 |

5–20 |

30–60 |

1.5–3 |

0.8–1.25 |

|

DY650 |

650 |

5–30 |

50–100 |

2.2–4 |

1.0–1.6 |

|

DY800 |

800 |

5–40 |

80–160 |

3–5.5 |

1.25–2.0 |

|

Mobile DY600 |

600 |

4–10 |

20–50 |

1.5–3 |

0.8–1.2 |

Application examples

A grain station in Henan uses a belt conveyor to continuously load the purchased wheat into a 20-ton grain truck, with a processing capacity of 60 tons per hour, which greatly saves manpower;

The carrot washing line of a fruit and vegetable factory in Shandong uses a multi-section belt conveyor to connect the cleaning machine, air dryer and sorting table to achieve full-process automatic transportation;

A large chicken farm in Yunnan uses a belt conveyor system to directly deliver feed from the central warehouse to the feeding troughs of each chicken house, improving the efficiency of automated feeding;

An organic fertilizer factory in Guangxi uses a belt conveyor to transport mixed fermented materials to the crushing and granulation area to achieve batch production of environmentally friendly fertilizers.

Manufacturer of agricultural belt conveyors

The company was established in 2008 and has a 10,000-square-meter modern production plant and more than a dozen processing equipment. The company has passed the ISO9001 quality system certification and the EU CE certification. From material selection, processing to assembly, it is strictly controlled at all levels, and the products are strictly debugged before leaving the factory.

The belt conveyors it produces are rich in types, including high-angle belt conveyors, mobile belt conveyors, telescopic belt conveyors, etc., with various models, and can also be specially designed according to user needs. The conveyor belts of the products are made of rubber, silicone, PVC, PU, etc., which can meet the transportation needs of various materials in the agricultural field. In addition, the company has a complete after-sales service, which can achieve a quick response within 30 minutes, rush to the customer's site for inspection within 72 hours, and provide quick on-site repairs within 24 hours.