Anti-static conveyor belt

Anti-static conveyor belt is a special conveyor belt designed to prevent static electricity accumulation and discharge. Its core function is to ensure that the static electricity generated during the conveying process can be discharged in a timely and safe manner through special materials and structural design, thereby avoiding equipment damage, product scrapping or safety accidents caused by static electricity discharge.

Application: Electronic manufacturing, semiconductor production, chemical industry, pharmaceuticals, food processing, etc.

Product Description

Anti-static conveyor belt is an industrial conveyor belt that has the ability to suppress static electricity, quickly conduct away static charges or neutralize static electricity through special material formula, structural design and process optimization. Its core feature is to control static electricity generated by friction, contact separation, etc. during the conveying process within a safe range through physical or chemical means, avoiding the harm caused by static electricity accumulation. It can effectively suppress or conduct static electricity generated by friction, charge separation and other factors during the conveying process, and is suitable for high-risk or precision scenes that are sensitive to static electricity.

What are the types of anti-static conveyor belts?

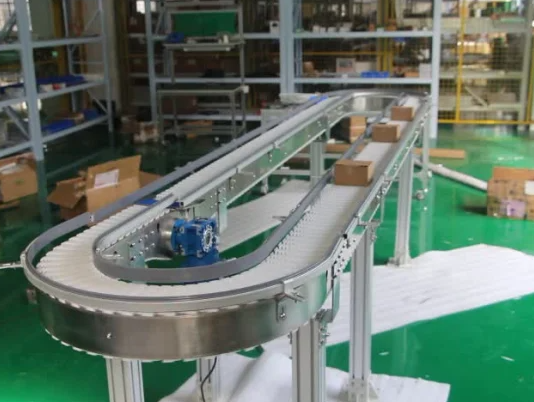

Anti-static flat conveyor belt: suitable for flat conveying, with smooth surface and low friction, suitable for conveying materials sensitive to static electricity.

Anti-static synchronous conveyor belt: suitable for occasions requiring synchronous transmission, with high precision and high stability.

Anti-static patterned conveyor belt: with patterned surface, suitable for occasions requiring increased friction, such as inclined conveying.

Anti-static conveyor belt video

What Makes It Anti-Static?

|

Component |

Function |

|

Conductive cover layer |

Disperses and conducts static charge |

|

Anti-static textile plies or cords |

Provides conductivity within the belt structure |

|

Grounded contact points |

Allow charges to discharge safely to earth |

|

Anti-static additives |

Embedded in the rubber, PVC, or PU for lasting protection |

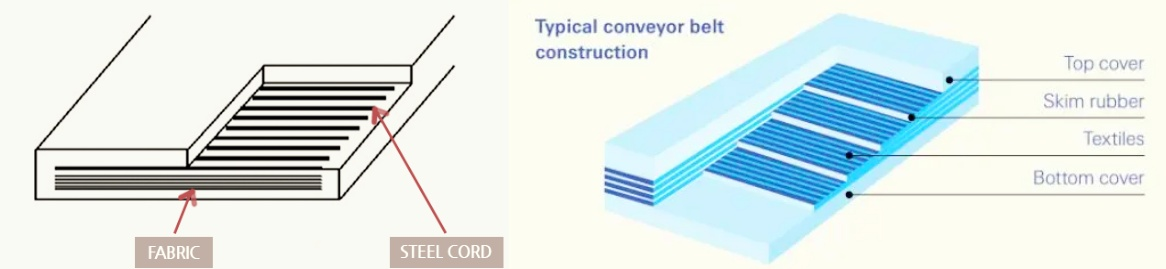

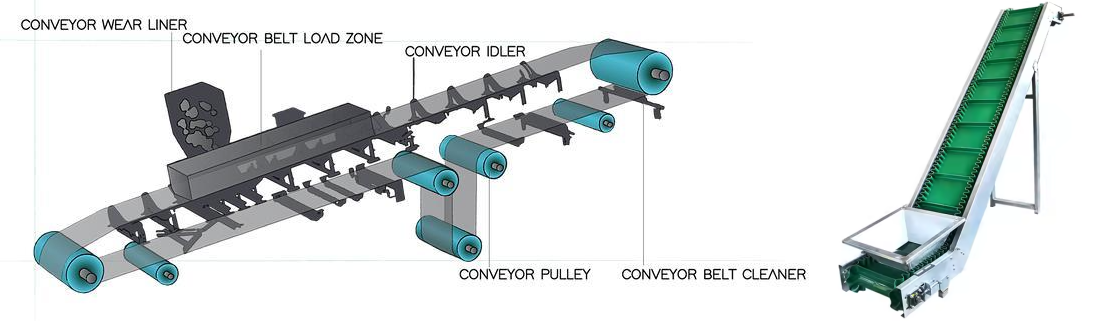

What is the structure of the anti-static conveyor belt?

Anti-static conveyor belts are designed to prevent the accumulation and discharge of static electricity during material transportation. Their structure typically consists of multiple layers, each with specific functions to ensure Anti-static performance, mechanical strength, and durability.Below is a detailed breakdown of their common structural components:

Core Layer (Base Fabric)、Antistatic Layer (Conductive Layer)、Top Cover (Carrying Surface)、Bottom Cover (Supporting Surface)、Edge Protection (Optional)、Joints and Fasteners.

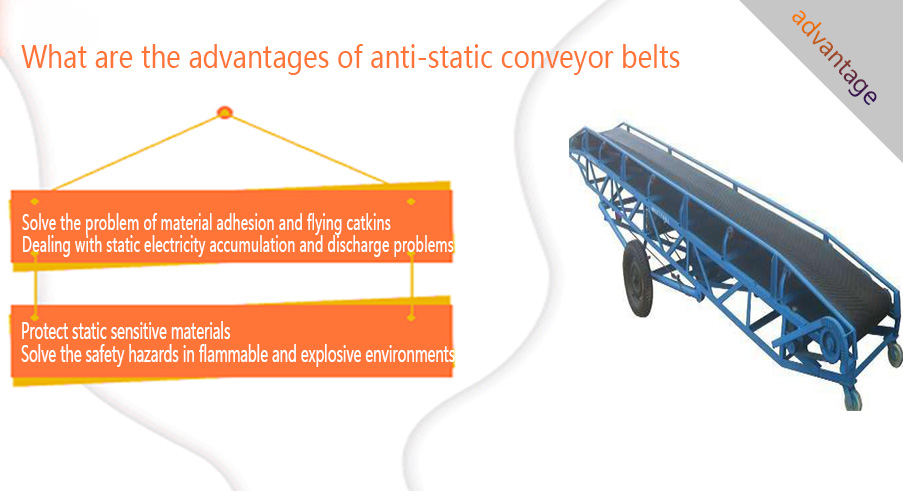

What are the advantages of anti-static conveyor belts

During the transportation process, materials will face key problems such as static electricity accumulation, safety hazards, quality damage, dust pollution, and equipment interference. Anti-static conveyor belts can effectively solve these challenges through their unique design and material properties.

Solve the problem of material adhesion and flying catkins

Conveyor belts in the textile and papermaking industries are prone to static electricity adsorption of fibers or dust, resulting in material adhesion, flying catkins or surface pollution. The surface of the anti-static conveyor belt is coated with an anti-static coating, and the surface is designed with concave and convex textures or guide grooves to promote material sliding and reduce the contact area.

Dealing with static electricity accumulation and discharge problems

When materials rub or when the conveyor belt contacts the equipment, static electricity accumulation may cause discharge. Conductive fibers are embedded in the conveyor belt or conductive coatings are added to form a conductive path to quickly conduct static electricity to the grounding device.

Protect static sensitive materials

Use highly conductive materials to ensure no static electricity accumulation. The smooth surface and thin design reduce friction and material damage, suitable for clean room environments.

Solve the safety hazards in flammable and explosive environments

In the chemical and powder processing industries, when conveying flammable gases, liquids or dust, the sparks generated by static discharge may become the ignition source, causing serious safety accidents. Anti-static conveyor belts significantly reduce the accumulation of static voltage by dissipating or conducting away the charge, thereby greatly reducing the possibility of sparks generated by static discharge.

Technical specifications of anti-static conveyor belts

|

Project |

Technical parameters/specifications |

Project |

Technical parameters/specifications |

|

Base material |

PVC/PU/Rubber/PE |

Belt structure |

Layered (fabric reinforced), integrated (steel cable core), modular |

|

Thickness |

2~20mm (covering rubber thickness 1.5~8mm) |

Thickness of wear-resistant layer affects life |

Width 300~3000mm |

|

Volume resistance |

≤10⁸Ω (conductive type) |

Surface resistance |

10⁴~10⁹Ω (conductive type: 10⁴~10⁶Ω; dissipative type: 10⁶~10⁹Ω) |

|

Wear resistance |

≤90mm³ |

Surface form |

Glossy/matte/rough/patterned surface |

|

Conventional working conditions |

1~3 years (rubber), 3~5 years (PU/Teflon) |

Ultra-high temperature environment |

6~12 months (metal mesh core) |

What is the application of anti-static conveyor belt?

Anti-static conveyor belts are widely used in flammable and explosive, electronic precision, dust-sensitive, high cleanliness and other static-sensitive scenes due to their characteristics of controlling static electricity.

Underground coal transportation:

The concentration of coal dust can easily reach the lower explosion limit (30-50g/m³), and static sparks may cause explosions. Select flame-retardant Anti-static conveyor belts, the covering layer contains conductive carbon black, the skeleton layer is embedded with a metal wire mesh, and a grounding copper belt is set every 10 meters to connect the tunnel grounding system.

Oil and gas transportation system:

Fuel vapor and air mix to form an explosive mixture, and the energy of static sparks may ignite. Use metal base belts and conductive rubber covering conveyor belts, the thickness of the aluminum foil base belt is 0.5mm, the surface is coated with 0.3mm, and thick conductive silicone is used to avoid metal friction sparks and quickly conduct away the charge.

Flour and starch processing:

The lower explosion limit of flour dust is 30g/m³, static sparks may cause deflagration, and dust is adsorbed on the surface of the conveyor belt, affecting the purity of the product. The surface of the food-grade Anti-static conveyor belt is smooth and non-porous, and food-grade conductive carbon nanotubes are added.

Chip wafer production line:

Electrostatic adsorption of dust particles contaminates the wafer surface, causing photolithography pattern defects. The surface of the conductive PVC conveyor belt is mirror-finished to reduce dust retention, and antioxidants are added to prevent material aging from causing increased resistance.

|

|

|

|

|

|

Underground coal transportation |

Oil and gas transportation system |

Flour and starch processing |

Chip wafer production lines |

|

main transportation lanes in mines, coal mining face chute, transportation of raw coal and coal powder |

fuel filling lines in refineries and gas stations, liquefied natural gas transportation |

raw grain cleaning, grinding, and packaging in flour mills, dry material transportation in starch production lines |

wafer transmission in photolithography and packaging, assembly line transportation of chip trays |

Recommendations for the purchase of anti-static conveyor belts

Clearly define application requirements: According to actual working conditions, consider factors such as working environment temperature and humidity, material type and its physical properties, and select appropriate materials and structures.

Choose reliable suppliers: Give priority to companies with good reputation and rich practical experience to ensure the product quality and after-sales service of anti-static conveyor belts.

If you need recommendations for specific materials, scenarios or anti-static conveyor belts, or comparative analysis with other conveyor belts, please provide more details and Dahan Machinery can further customize your questions.