Belt Conveyor Coal

The belt conveyor coal is a mechanized conveying equipment that uses a rubber conveyor belt as a load-bearing and traction component and is specially suitable for coal materials. The equipment has the characteristics of large conveying capacity, stable operation, and strong adaptability. It is suitable for transporting powdered, granular or lump coal, including raw coal, gangue and coal powder.

Weight Capacity(KG): 30-100 or Customized

Speed(m/min): 5-20 or Customized

Conveyor Height: Customized

Conveyor/Belt Width: Customized

What is a belt conveyor coal?

The belt conveyor coal is a continuous conveying equipment designed specifically for the characteristics of coal materials. It is a conveying machine suitable for coal materials of different particle sizes such as lump coal, coal powder, and coal gangue. With a rubber conveyor belt as a load-bearing component, the belt is driven by a driving roller to circulate to achieve horizontal, inclined or large-angle transportation of coal. Its core function is to optimize the structural design and material configuration to ensure efficient, stable and low-loss transportation for the characteristics of coal such as uneven particle size, large humidity changes, easy adhesion, and high stacking density (about 0.8~1.0t/m³).

Classification of belt conveyors coal

|

Classification method |

Picture |

Classification type |

Brief description |

Application scenario |

|

By structure form |

|

Fixed belt conveyor |

Fixed installation position, suitable for long-term use |

Fixed production lines such as underground coal mines, coal preparation plants, ports, etc. |

|

|

Mobile belt conveyor |

Movable frame, suitable for temporary transportation or occasions where frequent position adjustment is required |

Open-pit coal mines, stockpiling yards, temporary transportation points |

|

|

By layout method |

|

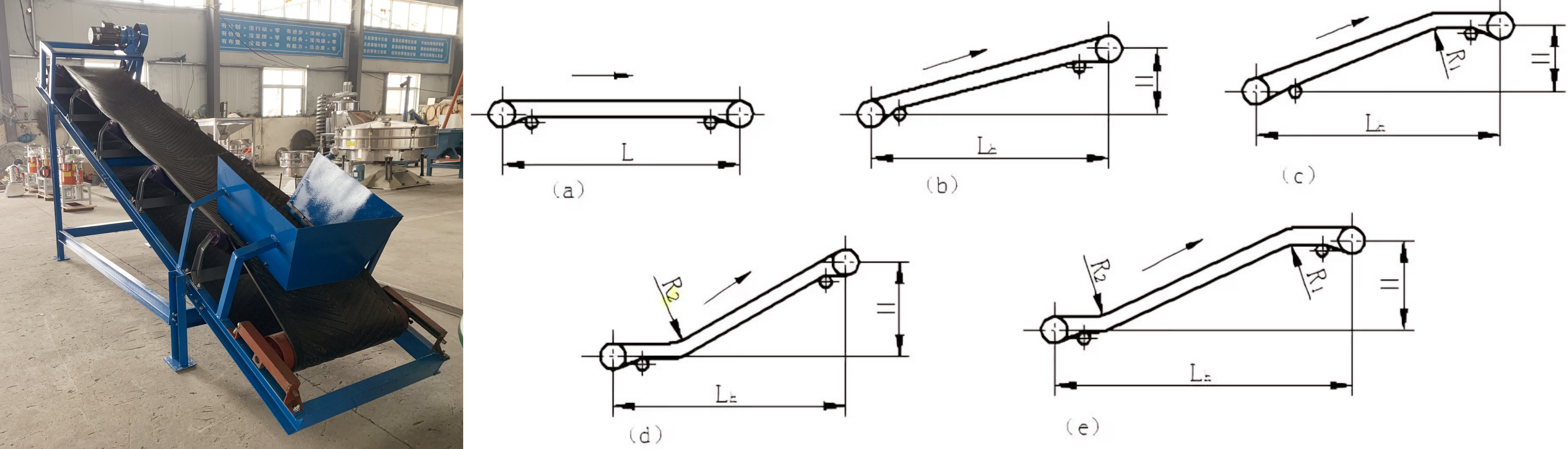

Horizontal belt conveyor |

The conveying line is basically horizontal, with a simple structure, mostly used for ground transportation |

Coal preparation plants, warehouses, and short-distance material transmission |

|

|

Inclined belt conveyor |

With a certain inclination (generally ≤18°), it is used for up/down transportation of coal |

Coal mine inclined lanes, coal preparation plant loading, port loading and unloading |

|

|

|

Vertical belt conveyor |

Special structure, the conveyor belt is vertical Layout, commonly used in places with limited space |

coal mine hoisting system, silo loading, deep processing plant |

Key parameter comparison

|

Type |

Typical inclination range |

Conveying distance range |

Common bandwidth |

Single machine transportation capacity |

|

Horizontal conveyor |

≤15° |

10~200 meters |

500~1400mm |

50~1500t/h |

|

Inclined conveyor |

15°~28° |

10~150 meters |

650~1200mm |

30~1000t/h |

|

Vertical conveyor |

90° (vertical) |

≤30 meters |

400~800mm |

10~300t/h |

Video of belt conveyor coal

Working principle of belt conveyor coal

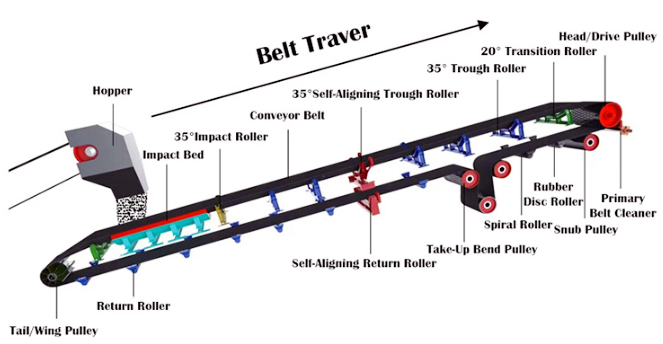

①Coal loading:Coal falls onto the conveyor belt through a hopper or guide trough, and the buffer roller at the tail can reduce material impact and prevent conveyor belt damage. For trough roller conveyors, the upper branch rollers are arranged in a trough shape (usually composed of 3 to 5 rollers), so that the conveyor belt forms a U-shaped cross-section, increasing the load and preventing coal from scattering.

② Continuous conveying:The conveyor belt runs forward at a constant speed (usually 0.8 to 4.5 m/s) driven by the transmission roller, and the coal moves with the conveyor belt by relying on the friction between it and the conveyor belt and its own gravity. The flat rollers of the lower branch support the unloaded conveyor belt to reduce the running resistance.

③ Coal unloading:When the conveyor belt runs to the transmission roller, the coal is separated from the conveyor belt due to inertia and falls into the subsequent equipment (such as coal bunker, crusher or another conveyor) through the head funnel. Through the unloading trolley or plow type unloader, the material can be unloaded at any position in the middle of the conveyor, which is suitable for multi-point unloading scenarios (such as the coal transportation system of a power plant feeding multiple coal bunkers).

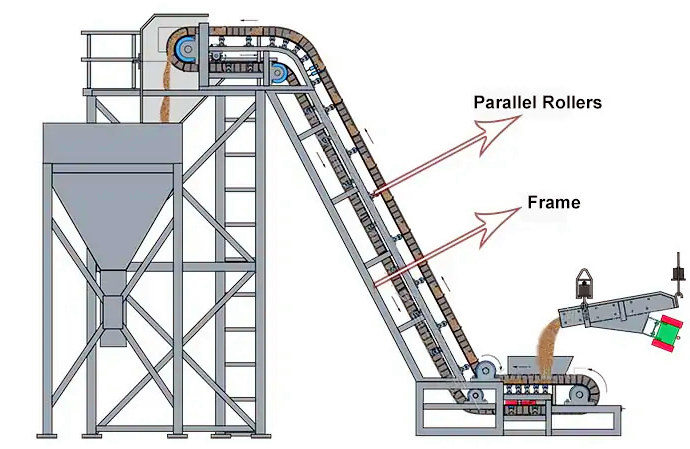

Structural composition of belt conveyor coal

The structural composition of belt conveyor coal mainly includes the following parts:

Conveyor belt: the main load-bearing part, usually made of rubber or polyester material, with good wear resistance and toughness.

Drum: the driving drum is used to drive the movement of the conveyor belt, usually installed at one end of the conveyor. The guide roller is used to support and guide the movement of the conveyor belt.

Frame: supports the entire conveyor structure, usually made of steel or aluminum alloy, with sufficient strength and stability.

Tensioning device: used to adjust and maintain the tension of the conveyor belt to ensure its normal operation.

Support frame: used to support the conveyor belt and other components, usually distributed under the conveyor.

These components work together to ensure that the belt conveyor coal can transport coal and other materials efficiently and stably.

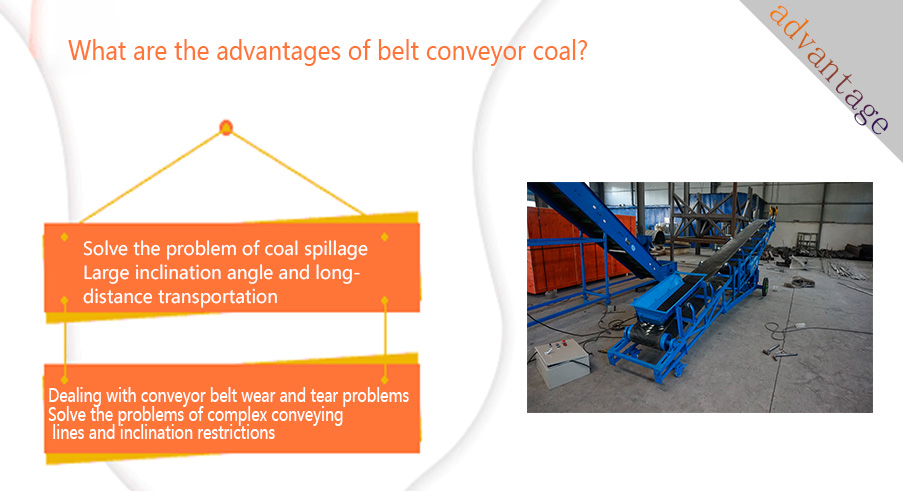

What are the advantages of belt conveyor coal?

Solve the problem of coal spillage: coal is easy to spill from both sides of the belt during loading and transportation, causing resource waste, equipment pollution and safety hazards. Belt conveyor coal can choose to use a raised sidewall conveyor belt in the inclined or turning section to prevent material leakage. The use of buffer beds and buffer rollers reduces material impact, helps to concentrate the material and reduce the probability of material spillage.

Large inclination angle and long-distance transportation: Use corrugated sidewall conveyor belts or pressure pulley devices to achieve vertical lifting or large-angle transportation (up to 90°), reducing the transfer and transportation links. Intermediate drive technology (such as multi-point drive motors) and high-strength steel rope core belts support continuous operation of a single conveyor for tens of kilometers, reducing material transfer losses.

Dealing with conveyor belt wear and tear problems: Coal is often mixed with hard objects such as gangue and iron blocks, which can easily scratch and puncture the conveyor belt. At the same time, the high abrasiveness of coal also causes the belt to age rapidly. Belt conveyors coal use highly wear-resistant rubber surface layers or steel rope core belts to improve wear resistance and strength. Tear detection devices are configured in some large systems to achieve emergency shutdown.

Solve the problems of complex conveying lines and inclination restrictions: Coal transportation paths often need to cross different height differences and direction changes, especially under the conditions of complex mining terrain and limited plant layout, ordinary flat belts are difficult to handle. The large-angle structure allows the maximum conveying angle to reach 90°, which is suitable for vertical or steep slope conveying in narrow spaces. By controlling the belt tension and support structure, long-distance curved conveying can be achieved.

Technical specifications of belt conveyor coal

|

Category |

Technical specification item |

Description and parameter range |

|

Basic parameters |

Conveying capacity (t/h) |

50~5000 t/h |

|

Belt width (mm) |

500, 650, 800, 1000, 1200, 1400, 1600, 1800, 2000, etc. |

|

|

Conveying speed (m/s) |

0.8~4.0m/s (low speed is suitable for large particles, high speed is suitable for powdered materials) |

|

|

Conveying length (m) |

Horizontal conveying: ≤2000 m; inclined conveying: ≤500 m |

|

|

Inclination angle (°) |

≤18° (depending on the material characteristics, coal powder can be appropriately increased to 20°, and anti-slip design is required) |

|

|

Belt type |

Material |

Rubber belt (ordinary type, wear-resistant type, high temperature resistant type), steel cord belt, nylon canvas belt, etc. |

|

Strength grade (N/mm) |

Ordinary rubber belt: 56~300 N/mm; Steel cord belt: 1000~6300 N/mm |

|

|

Thickness of cover layer (mm) |

Working surface: 3~15 mm (wear-resistant layer); Non-working surface: 1.5~4mm |

|

|

Drive mode |

Single drum drive, double drum drive, multi-motor distributed drive |

|

|

Motor power (kW) |

5.5~1000 kW |

|

|

Drum diameter (mm) |

Drive drum: 315, 400, 500, 630, 800, 1000, etc.; Redirection drum: 219, 273, 325, etc. |

|

|

Roller system |

Roller form |

Trough roller (bearing section, angle 30°/45°), parallel roller, self-aligning roller, buffer roller |

|

Roller spacing (mm) |

Bearing section: 1000~1500 mm; Return section: 2000~3000 mm (Buffer roller spacing can be reduced to 300~600 mm) |

|

|

Roller material |

Seamless steel pipe (surface galvanized or rubber coated), polymer material (corrosion resistant) |

Technical Parameters of belt conveyor coal specification

|

Belt width(mm) |

300 |

400 |

500 |

650 |

800 |

||||||||

|

Sidewall height(mm) |

40 |

60 |

60 |

80 |

80 |

120 |

120 |

160 |

120 |

160 |

200 |

240 |

|

|

Conveying Capacity:Q3/h |

30° |

15 |

14 |

20 |

34 |

46 |

71 |

104 |

120 |

128 |

157 |

195 |

235 |

|

45° |

11 |

10 |

14 |

26 |

35 |

57 |

83 |

97 |

102 |

127 |

157 |

195 |

|

|

60° |

8 |

7 |

10 |

18 |

25 |

40 |

58 |

69 |

72 |

90 |

112 |

142 |

|

Application of belt conveyor coal

Price of belt conveyor coal

|

Model |

Belt width (mm) |

Length (m) |

Power (kW) |

Speed (m/s) |

Output (t/h) |

Price (4/set) |

|

Horizontal sand conveyor belt |

B500 |

3 |

4-7.5 |

1.25-2.0 |

40-80 |

2120-10750 USD |

|

Inclined sand conveyor belt |

B650 |

3 |

7.5-11 |

1.25-2.0 |

80-120 |

4100-24230 USD |

|

Vertical sand conveyor belt |

B800 |

4 |

7.5-15 |

1.25-2.0 |

120-200 |

5500-36300 USD |

|

Fixed sand conveyor belt |

B400 |

3 |

4-7.5 |

1.25-2.0 |

30-60 |

2000-9430 USD USD |

|

Mobile gravel conveyor belt |

B1000 |

5.5 |

7.5-22 |

1.25-2.0 |

200-320 |

14800-249000 USD |

The price and specifications of gravel conveyor belts vary greatly depending on the following factors:

Model: Different types of belt conveyors have different conveying capacities and applicable scopes, which directly affect the manufacturing cost and price of the equipment.

The materials include rubber, nylon, etc. Different materials have different wear resistance, tear resistance, and service life, which affect the price and specifications.

Configuration: Whether the roller is coated, the number of rollers, the number of strips, and other configurations will also affect the price.