Belt Conveyor Hay

The belt conveyor hay is a mechanical device specially used for conveying hay. It uses a conveyor belt as a carrier and drives the conveyor belt to operate through a driving device, thereby realizing continuous conveying of hay.

Conveying distance: up to 203m

Conveying capacity: 30-3000 tons/hour

What is a belt conveyor hay?

The belt conveyor hay is a mechanical device mainly used for automatically conveying hay bales in an agricultural environment. It is commonly used in agricultural fields, such as pastures, farms, etc., and the hay bales placed on it are efficiently transported from one location to another through one or more continuously moving belts. . Belt conveyor is a common material conveying equipment that conveys materials through the continuous movement of the belt. For hay, it usually consists of a belt, a drive roller, a tensioning device and some support frames. The belt is usually made of wear-resistant material and can withstand the friction and pressure of hay.

Classification of belt conveyors hay

①Classification by structural form

Fixed belt conveyor hay: installed in a fixed position, with a fixed conveying route and conveying distance, suitable for long-term stable operation of hay conveying systems, such as hay warehouses on farms, feed processing plants and other places.

Mobile belt conveyor: with a movable frame and walking mechanism, it can carry out hay conveying operations at different locations as needed, with high flexibility. Commonly used for hay transportation at field hay harvesting sites or temporary stacking points.

Telescopic belt conveyor: The length of the conveyor belt can be adjusted according to actual needs, and can adapt to different conveying distances and site changes. It is suitable for some occasions where the conveying length needs to be flexibly changed, such as ports, freight yards and other places for loading, unloading and transshipment of hay.

②Classification by conveying direction

Horizontal conveying belt conveyor hay: mainly used for conveying hay on the same horizontal plane, suitable for conveying hay from one area to another horizontal area, such as from the hay stacking area to the processing area.

Inclined conveying belt conveyor: used to convey hay from a lower position to a higher position, or from a higher position to a lower position. When designing an inclined conveyor belt conveyor, it is necessary to consider the inclination angle of the conveyor belt, the characteristics of the hay, and measures to prevent the hay from slipping.

Turning conveyor belt conveyor hay: It can realize the turning of hay during the conveying process, can adapt to complex site layout, and make the hay conveying system more flexible. However, components such as conveyor belts and rollers at the turns need special design to ensure the smooth conveying of hay and the normal operation of the conveyor belt.

Video of belt conveyor hay

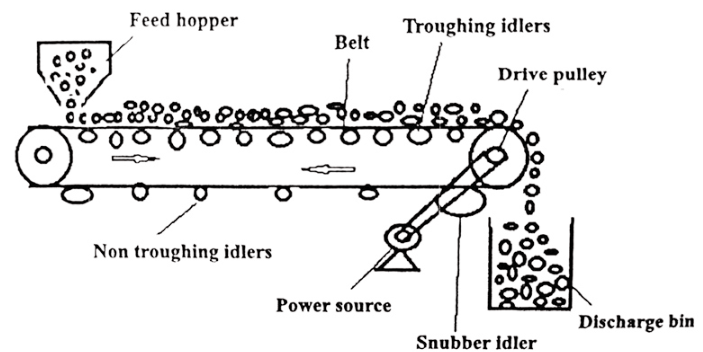

Working principle of belt conveyor hay

The belt conveyor hay hay mainly relies on the continuous movement of the conveyor belt to realize the conveying of hay. The motor in the drive device transmits power to the transmission roller through the reducer, and friction is generated between the transmission roller and the conveyor belt, thereby driving the conveyor belt to operate. The hay is placed on the conveyor belt and is transported from one end to the other as the conveyor belt moves. During the conveying process, the rollers play the role of supporting the conveyor belt and hay to ensure the smooth operation of the conveyor belt; the tensioning device adjusts the tension of the conveyor belt at any time to ensure the normal operation of the conveyor belt.

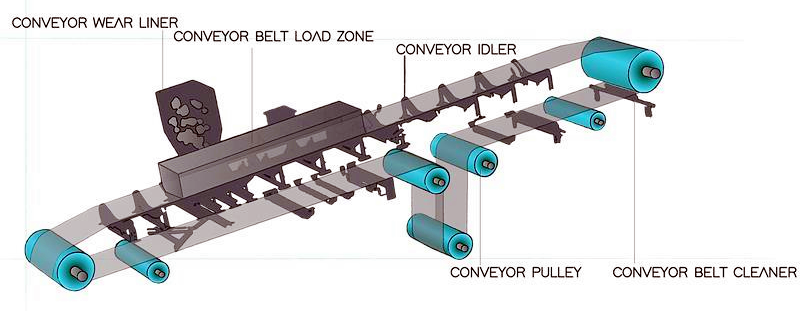

Structure of belt conveyor hay

The belt conveyor hay is mainly composed of conveyor belt, drive device, roller, tensioning device, frame and other basic components.

Conveyor belt: It is the core component of belt conveyor hay, used to carry and transport hay. Common conveyor belt materials include rubber, canvas, PVC, PU, etc., and the appropriate material can be selected according to the use environment and hay characteristics.

Drive device: The motor provides power for the entire conveying system. Usually, an electric motor with suitable power and speed is selected to meet the speed and load requirements of hay transportation.

Drive roller: It is in direct contact with the conveyor belt and drives the conveyor belt to operate through friction.

Roller: It is used to support the conveyor belt and the hay on it, so that the conveyor belt maintains a stable operating state, reduces the sagging and swinging of belt conveyor hay, and reduces the operating resistance.

Tensioning device: Its function is to keep the conveyor belt in a certain tension, prevent the conveyor belt from slipping or loosening during operation, ensure that there is sufficient friction between the conveyor belt and the drive roller, and ensure the stability of the conveying process.

Frame: It is the supporting structure of the belt conveyor hay, usually welded or bolted by steel, used to install and fix the conveyor belt, drive device, roller, tensioning device and other components to form a complete conveying system.

What are the advantages of belt conveyor hay?

Conveyor belt characteristics: Anti-slip design on the surface (such as patterns or rubber bumps). Lightweight material to reduce energy consumption. Anti-static treatment (to prevent hay debris from adsorbing).

Anti-dust design: closed conveyor belt or side baffle, can also be equipped with a spray system or dust removal device (depending on environmental requirements).

Flexible conveying method: The belt conveyor hay can adjust the conveying length and height as needed to adapt to different conveying scenarios.

Anti-winding and clogging: Regularly clean the hay debris on the rollers and drums. Use self-cleaning rollers or scraper devices.

Tilt angle: The friction of hay is small, and the recommended tilt angle is not more than 15°~20°. If a large angle is required, it is necessary to add side guards or use corrugated baffle belts.

Mobile design: equipped with wheels or traction devices for easy transfer between fields or sites. Can be driven by tractors or other power sources.

Technical specifications of belt conveyors hay

|

Belt width |

Conveying length(m) |

Conveying speed |

Conveying amount |

||

|

B400 |

≤10 |

12-15 |

5-30 |

1.25-2.0 |

30-60 |

|

3 |

3-4 |

4-7.5 |

|||

|

B500 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

40-80 |

|

3 |

4-5.5 |

5.5-7.5 |

|||

|

B650 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

80-120 |

|

4 |

7.5 |

7.5-11 |

|||

|

B800 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

120-200 |

|

4 |

7.5 |

7.5-15 |

|||

|

B1000 |

≤10 |

10-20 |

20-40 |

1.25-2.0 |

200-320 |

|

5.5 |

7.5-11 |

11-22 |

|||

|

B1200 |

≤10 |

10-20 |

20-40 |

1.25-2.0 |

290-480 |

|

7.5 |

7.5-15 |

15-30 |

|||

|

B1400 |

≤10 |

10-20 |

<20-40 |

1.25-2.0 |

400-680 |

|

11 |

15-22 |

22-45 |

|||

|

B1600 |

≤10 |

10-20 |

<20-50 |

1.25-2.0 |

600-1080 |

|

15 |

22-30 |

30-75 |

|||

|

B1800 |

≤10 |

10-20 |

<20-50 |

1.0-2.0 |

200-1500 |

|

18.5 |

30-45 |

45-110 |

|||

|

B2000 |

≤10 |

10-20 |

<20-40 |

1.0-2.0 |

1000-2000 |

|

22 |

45-55 |

55-132 |

|||

|

B2400 |

≤10 |

10-20 |

<20-40 |

1.0-2.0 |

1500-3000 |

|

30 |

55-75 |

75-185 |

|||

Applications of belt conveyors hay

Belt conveyors hay are widely used in modern agriculture, mainly focusing on improving hay processing efficiency, reducing labor intensity and optimizing farm operation processes. After hay harvesting, belt conveyors hay can collect the cut hay directly in the field and transport it to transport vehicles or temporary storage points. In the process of hay briquetting, crushing, etc., the conveyor can serve as a bridge to connect different processing equipment to realize the automatic flow of materials and improve processing efficiency.

① Transport the bundled hay bales from the edge of the field to the storage warehouse or hay shed.

② Conveniently transport the stored hay bales to the livestock feeding area.

③ In the hay processing production line, connect different processing equipment to realize the automatic flow of materials.

Manufacturer of belt conveyors hay

Han Machinery's belt conveyors hay have various types, such as mobile and large-angle, which can be used for hay transportation. The equipment has the characteristics of strong conveying capacity and long conveying distance. The conveying capacity ranges from 30-3000 tons/hour and the conveying length can reach 203 meters. The equipment has flexible layout and can be used alone or in combination with other equipment. It can flexibly receive materials from one or more points according to the process requirements, and can also unload materials to multiple points or several sections.