Belt Conveyor Soybeans

Belt conveyor soybeans is a belt conveyor specially used for conveying soybeans and other grain materials. It is often used in grain depots, grain processing plants, oil and fat factories, port terminals and other places. Its main function is to transport soybeans from one process or area to another process or storage area to achieve continuous and automated transportation of materials.

Conveying capacity: 15-76m³/h

Belt width: 1000-1400mm

Ring height: 120-400mm

Applicable materials: dusty, small particles and small block materials

What is belt conveyor soybeans?

Belt conveyor soybeans is a continuous conveying equipment specially used for transporting soybeans and other granular materials. It is suitable for grain processing, feed, warehousing and other industries. In the process of soybean transportation, the continuous movement of the conveyor belt is used to achieve efficient transmission of soybeans, which is usually used to separate soybeans of different particle sizes. Common screening meshes include 20 mesh, 30 mesh and 40 mesh, etc. Choosing the right mesh can effectively improve the purity and quality of soybeans. In addition, the conveying capacity of the conveyor is generally between 10 tons/hour and 50 tons/hour.

Classification of belt conveyor soybeans

As a specific application of belt conveyors, the classification method of belt conveyor soybeans can refer to the classification method of general belt conveyors and be subdivided in combination with the actual needs of soybean transportation. According to the structural form:

Fixed belt conveyor: The installation position is fixed, suitable for long-distance, large-volume continuous transportation, and is a common type in grain depots, ports and large processing plants.

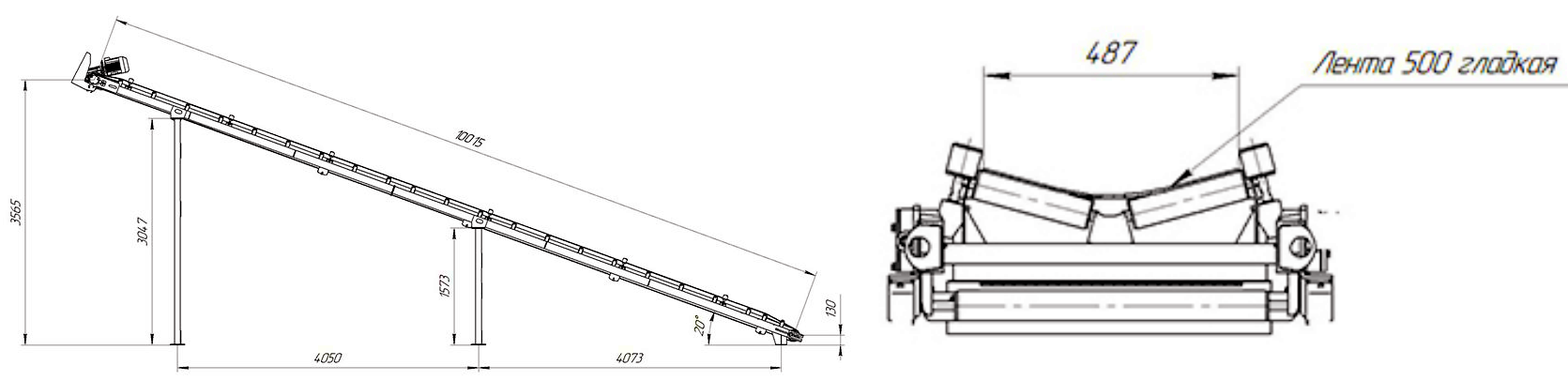

Mobile belt conveyor: It has the characteristics of being movable and liftable. The belt conveyor has wheels under it, which can be easily moved to different work locations. It is suitable for occasions where the conveying position needs to be flexibly adjusted. It is convenient for loading and unloading soybeans in grain depots, ports, docks and other places. It can flexibly adjust the conveying height and angle to adapt to different work scenes, such as grain depot warehouse unloading, bulk grain collection and transportation, etc.

Retractable belt conveyor: The conveyor length can be adjusted, which is convenient for material loading and unloading in areas with varying lengths. It is often used for loading and unloading operations of vehicles or ships.

Large-angle belt conveyor: The conveyor belt with corrugated sidewalls and partitions can be used to convey soybeans at a larger angle, saving space.

Video of belt conveyor soybeans

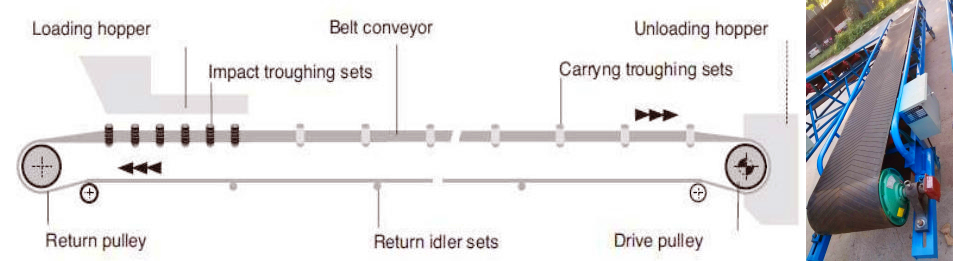

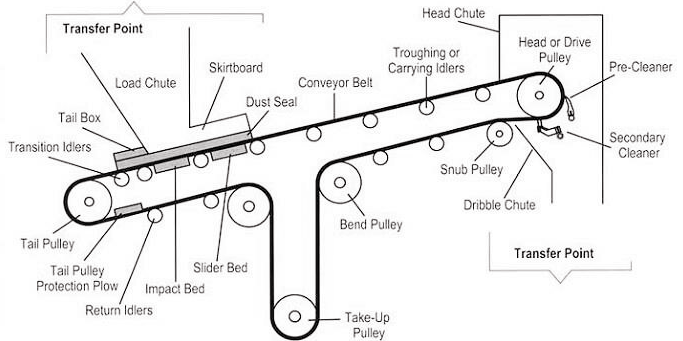

What is the working principle of belt conveyor soybeans?

Belt conveyor soybeans is a common equipment used for conveying soybeans and similar granular materials. It uses a continuous conveyor belt as a traction and load-bearing component, and uses a driving device to circulate the belt to achieve horizontal or inclined conveying of materials.

Throughout the process, the continuous movement of the conveyor belt is the key to conveying soybeans from one point to another. The roller supports the conveyor belt and the material on it, the driving device provides power, and the tensioning device ensures the normal operation of the conveyor belt. By adjusting the speed and width of the conveyor belt, the conveying amount of soybeans can be controlled.

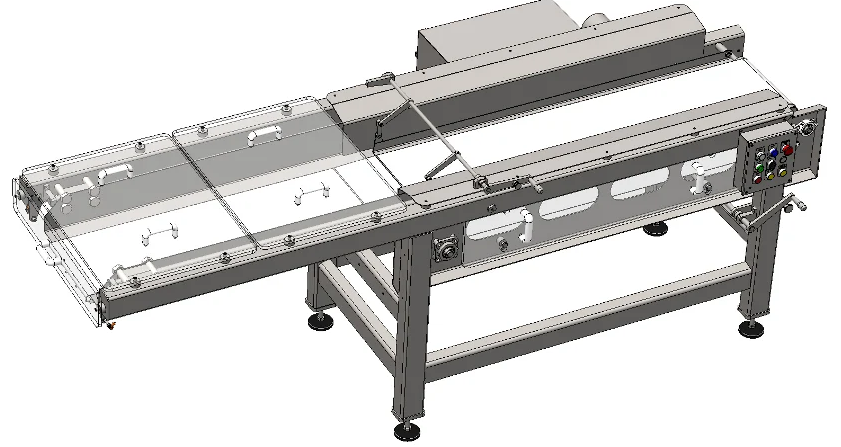

Structure of belt conveyor soybeans

Belt conveyor soybeans is a kind of equipment used to transport soybeans or other materials, mainly composed of the following parts:

Conveyor belt: It is the key component of belt conveyor, directly contacting and carrying soybeans. Common materials include rubber, PVC, etc., with wear resistance, corrosion resistance, anti-aging and other properties. Different patterns and structures can also be selected according to the conveying requirements. For example, herringbone pattern conveyor belt can increase friction and prevent soybeans from slipping.

Roller: It includes drive roller, redirection roller, etc. The drive roller drives the conveyor belt through the drive of the motor and the reducer; the redirection roller is used to change the running direction of the conveyor belt.

Roller: It is used to support the conveyor belt and the soybeans on it, reduce the sag and running resistance of the conveyor belt. Common rollers include parallel rollers, trough rollers, etc. Trough rollers can make the conveyor belt form a trough shape, increase the conveying capacity and stability of soybeans.

Frame: It is the supporting structure of the belt conveyor, usually welded with steel or steel pipes, and requires sufficient strength and rigidity.

Driving device: It is composed of motor, reducer, coupling, etc., which provides power for the belt conveyor and makes the conveyor belt run at a certain speed. According to the requirements of conveying volume and conveying distance, motors and reducers of different power and speed can be selected.

Features of belt conveyor soybeans

Wide range of conveying materials: It can convey both loose materials and pieced items. It can be conveyed by a single unit, or it can be composed of multiple units or with other conveying equipment to form a horizontal or inclined conveying system.

Large conveying capacity: The conveying capacity of soybean belt conveyor is large, the conveying length can reach 203 meters, and the conveying capacity is between 30 and 3000 tons/hour. It can be designed in combination with the user's conveying length, process requirements, and actual site conditions.

Anti-slip and wear-resistant design: The surface of belt conveyor soybeans adopts concave and convex anti-slip patterns or rubber covering layer to reduce the soybean breakage rate (≤0.5%) and adapt to the conveying of materials with a moisture content of ≤15%.

A variety of materials are available: the conveyor belt is made of rubber, silicone, PVC, PU, etc. In addition to being used for the transportation of ordinary materials, it can also meet the transportation of materials with special requirements such as oil resistance, corrosion resistance, and anti-static.

Integrated screening function: Belt conveyor soybeans can be equipped with a vibrating screen (screening efficiency ≥ 95%) or a drum screen, the mesh size covers 6-30 mesh (aperture 0.6-3.35mm), and supports multi-level stratified screening (such as 12 mesh to remove impurities and 20 mesh to sort broken beans).

Technical parameters of belt conveyor soybeans

|

Width (mm) |

Conveying length (m) Power (kw) |

Conveying length (m) Power (kw) |

Conveying length (m) Power (kw) |

Conveying speed (m/s) |

Conveying volume (t/h) |

|

400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 |

30-60 |

|

500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 |

40-80 |

|

650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 |

80-120 |

|

800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 |

120-200 |

|

1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 |

200-320 |

|

1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 |

290-480 |

|

1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 |

400-680 |

|

1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 |

600-1080 |

|

1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 |

800-1500 |

|

2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 |

1000-2000 |

|

2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 |

1500-3000 |

Suitable use scenarios of belt conveyor soybeans

Belt conveyor soybeans is mainly used for continuous conveying of soybeans and related products (such as soybeans, green beans, soybean meal, etc.), and its suitable use scenarios have a certain breadth. Soybean belt conveyors are suitable for scenes that require continuous, efficient, and low-loss transportation of granular materials, especially for agricultural production areas, grain and oil processing enterprises and large logistics hubs.

Grain depot in-and-out warehouse transportation

Raw material transportation before oil pressing

Material transfer before and after soybean selection and grading

Bulk soybean transfer system at the wharf

Application cases of belt conveyor soybeans

|

Application industry |

Usage scenario/location |

Conveying materials |

Conveying form |

Features/Requirements |

|

Grain storage |

National grain depot |

Raw grain soybeans |

Horizontal + inclined conveying |

Large conveying volume, dust and rain protection required |

|

Grain and oil processing |

Raw material workshop of edible oil factory |

Soybeans after cleaning |

Horizontal conveying |

Continuous operation, speed control required |

|

Soybean product processing |

Tofu production workshop |

Washed soybeans |

Horizontal conveying |

Food-grade conveyor belts are required, waterproof and corrosion-resistant |

|

Feed processing |

Feed factory batching system |

Soybean meal |

Horizontal conveying |

Sealed structure to reduce dust pollution |

|

Port Port terminal |

Bulk grain unloading and transfer area |

Bulk soybeans |

Inclined transportation |

Large flow, equipment needs to be corrosion-resistant and wind and rain-resistant |

|

Logistics warehousing |

Grain and oil e-commerce sorting center |

Bagged soybeans |

Horizontal transportation |

Adapt to automated logistics system, stable transportation rhythm |

|

Seed company |

Soybean seed packaging and sorting line |

Commodity soybeans |

Slope transportation |

Gentle transportation to avoid seed damage |

|

Farmer purchasing station |

Primary purchasing point for agricultural products |

Raw grain soybeans |

Mobile transportation |

Flexible and mobile, convenient for temporary use in the field |

|

Farm self-use |

Self-built grain warehouse or processing site |

Self-grown soybeans |

Horizontal transportation |

Simple structure, easy to maintain and operate |