Belt Conveyor Corn

Belt conveyor corn is a continuous conveying equipment widely used in grain handling, storage and processing industries. It is mainly used for horizontal or inclined conveying of corn grains, corn stalks and other materials. It uses a continuous rubber or plastic conveyor belt as a load-bearing and traction component, and drives the conveyor belt to circulate through a drive device, thereby realizing long-distance and large-scale transportation of materials.

Highlights:

Corrugated sidewall conveyor belt prevents spilling and bag dropping

Small space occupation, saving 20% to 30% of investment costs

What is belt conveyor corn?

Belt conveyor corn is a continuous conveying equipment dedicated to granular materials such as corn. Its core function is to achieve efficient horizontal or inclined conveying of corn. At the same time, it can complete impurity separation or particle classification through a built-in vibrating screen. The screening mesh range is usually 10-60 mesh (aperture 1.6-0.3mm), and the screen specifications can be flexibly adjusted according to the cleanliness or classification requirements of corn.

The equipment uses anti-skid and wear-resistant rubber belts. The conveyor belt width is commonly 500-1200mm, the conveying speed is 0.8-2.5m/s, the maximum conveying distance of a single machine can reach 50 meters, and the processing capacity per hour is about 5-30 tons. Corn screening can be matched with screens of different mesh sizes.

For example, for corn with more impurities, a 10-2 mesh screen can be used for coarse screening to remove large particles of debris; for corn with high quality requirements, a 40-60 mesh screen can be used for further screening to ensure that the corn particles are uniform in size, effectively improving the quality and efficiency of subsequent processing of corn.

Video of belt conveyor corn

Conveying angle of belt conveyor corn

①30° conveying angle

Features: small inclination, stable conveying, and materials are not easy to slide back. The belt tension requirement is low, and the equipment runs stably.

Applicable occasions: suitable for horizontal or slightly inclined conveying scenarios, such as conveying in warehouses, horizontal conveying on the ground, or loading and unloading operations with a slight drop.

②45° conveying angle

Features: medium inclination, lifting height and conveying distance are taken into account, and good stability can be maintained. The belt surface can be equipped with ribs or patterned conveyor belts to prevent materials from slipping.

Applicable occasions: used for stacking or loading operations with a certain height difference, such as from the ground to the truck cargo box, from the pile to the storage facility.

③70° conveying angle

Features: nearly vertical, high lifting efficiency, but high requirements for the anti-slip performance of the conveyor belt. Generally, it is combined with a skirt conveyor belt or a bucket-shaped lifting structure to prevent corn kernels from sliding back.

Applicable occasions: occasions where space is limited and rapid vertical lifting is required, such as from a pit to a high-level storage bin.

④90° conveying angle

Features: completely vertical conveying, high efficiency, and small footprint.

Applicable occasions: suitable for process flows of vertically lifting materials, such as top feeding of silos, feeding of packaging equipment, etc.

|

Conveying angle |

Conveying stability |

Lifting height |

Applicable scenarios |

Remarks |

|

30° |

High |

Low |

Horizontal conveying, slight inclination |

Regular belts are sufficient |

|

45° |

Higher |

Medium |

Loading, stacking, etc. |

Recommended patterned or sidewall belts |

|

70° |

Medium |

High |

Storage lifting, conveying with large drop |

Non-slip belts or sidewall designs are required |

|

90° |

Low (non-slip required) |

Very high |

Vertical feeding, silos, elevator matching |

Special structures such as skirt belts or buckets are required |

What are the types of belt conveyor corn?

|

Types |

Picture |

Structure form |

Applicable occasions |

Feature description |

|

Ordinary fixed belt conveyor |

|

Horizontal linear structure |

Storage, loading, unloading and other places |

Suitable for short-distance or fixed route transportation, easy maintenance |

|

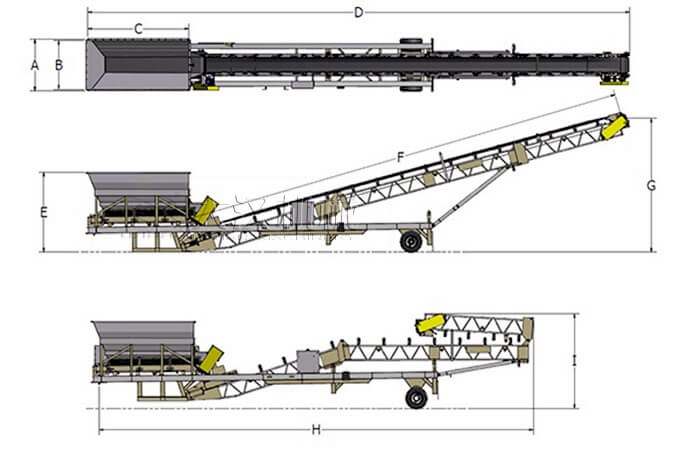

Mobile belt conveyor |

|

Wheeled movable structure |

Temporary work site, loading port |

Strong adaptability, suitable for material transfer in unfixed positions |

|

Inclined belt conveyor |

|

With lifting angle |

Feeding, storage stacking, height difference transportation |

Can overcome a certain height difference, some models with side guards to prevent materials from sliding down |

|

Belt conveyor with skirt baffles |

|

Wavy side guard belt structure |

Large inclination or vertical lifting occasions |

Suitable for large angle or even near-vertical transportation to prevent corn from sliding |

|

Enclosed belt conveyor |

|

Belt-wrapped structure |

Dust-proof, rain-proof, and pollution-proof places |

Reduce dust spillage and pollution risks, suitable for working environments with high environmental protection requirements |

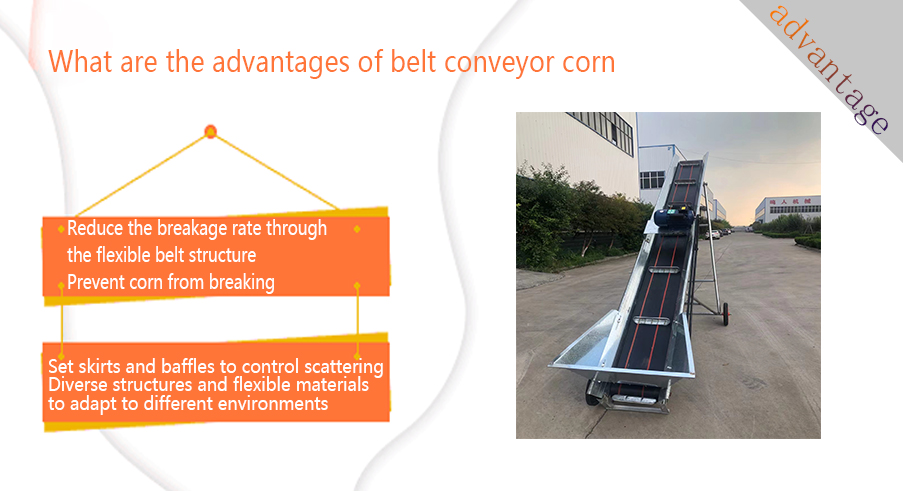

What are the advantages of belt conveyor corn

①Reduce the breakage rate through the flexible belt structure

Belt conveyor Corn is coated with soft materials (such as PVC, rubber), with good surface elasticity and small impact on corn; the conveying process is smooth and continuous, without violent shaking and intermittent feeding, reducing secondary collisions; buffer rollers can be installed on the belt surface to further reduce the force on the material.

② Prevent corn from breaking

The belt conveyor has a uniform and stable running speed, and the corn and the conveyor belt are relatively static, without violent collisions and friction, which greatly reduces the crushing of corn caused by mutual collision or collision with conveying equipment. When designing the conveying line, try to reduce bends and drops to avoid corn from breaking due to sudden changes in direction or falling during transportation.

③ Set skirts and baffles to control scattering

Cornal wavy baffles or baffles can be installed on both sides of the belt conveyor corn to prevent corn from slipping out during movement; add a guide trough at the loading point to guide the material to fall evenly into the belt body; configure a block structure at the inclined section of the belt to improve the climbing conveying capacity and avoid slipping.

④ Diverse structures and flexible materials to adapt to different environments

Carbon steel, stainless steel or galvanized materials can be selected according to the use requirements to adapt to humid, corrosive or hygienic places; it can be designed as fixed or mobile to cope with seasonal operations and different sites; the belt body can be set to run in a straight line, inclined or curved according to the working space.

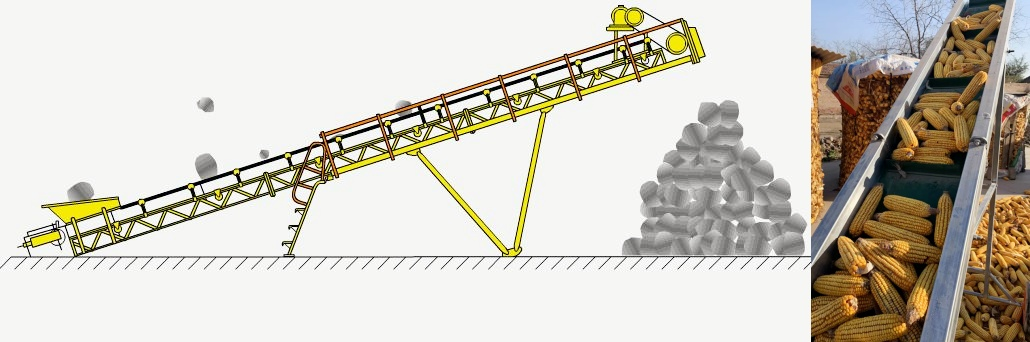

Working principle of belt conveyor corn

The motor starts and supplies power to the drive warehouse through the agricultural production device. The drive rotor rotates and drives the pipeline to run continuously in a cycle.

The corn meets the pipeline belt through the feeding device (such as a funnel). The belt conveyor corn transports the corn smoothly to the designated location through the unloading device (such as a chute or scraper). The tensioning device and roller ensure that the pipeline transportation remains stable during operation to prevent the material from spilling.

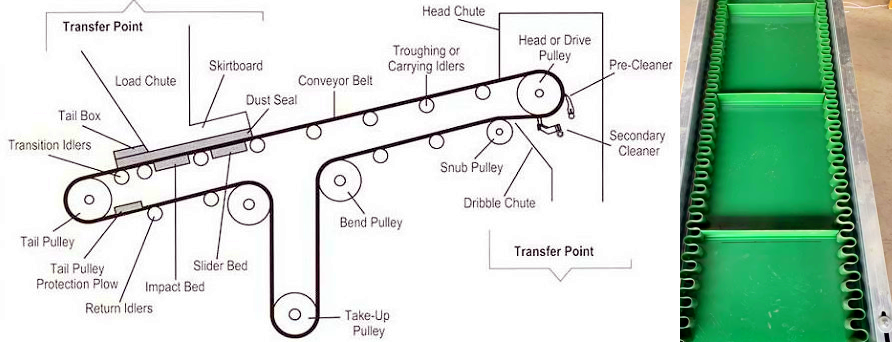

Structure of belt conveyor corn

Drive device: usually composed of a motor and a reducer, providing the power required for the conveyor to operate.

Conveyor belt: It is an endless belt or polymer material belt that is a component that carries corn.

Drum: includes a drive drum and a redirecting drum. The drive roller is connected to the drive device and drives the conveyor belt through the friction between it and the conveyor belt. The redirection roller is located at the other end of the conveyor and changes the direction of movement of the conveyor belt.

Rollers: Support the conveyor belt and the corn on it to keep the conveyor belt linear and reduce running resistance. Rollers are usually arranged in groups, including trough rollers and parallel rollers.

Tensioning device: Used to adjust the tension of the conveyor belt to ensure that there is enough friction between the conveyor belt and the drive roller to avoid slipping, and prevent the conveyor belt from being too loose and affecting normal operation.

Frame: The structure that supports the entire conveyor, including rollers, rollers, drive devices and other components.

Feeding and unloading device: Used to smoothly place corn on the conveyor belt (feeding) and remove corn from the conveyor belt (unloading).

Applicable materials and screening parameters

Belt conveyor corn can convey corn materials in various forms. The common material particle sizes and screening mesh numbers correspond to the following:

|

Material type |

average particle size range |

corresponding screening mesh number |

|

Corn whole kernels |

5-10 mm |

2-4 mesh |

|

Corn crumbs |

1-3 mm |

8-18 mesh |

|

Corn cob powder |

0.5-1 mm |

20-40 mesh |

|

Corn starch |

0.074-0.15 mm |

100-200 mesh |

Belt conveyor Corn models and parameters

|

Bandwidth B (mm) |

300 |

400 |

500 |

650 |

800 |

|||||||||||

|

Sidewall height (mm) |

40 |

60 |

60 |

80 |

80 |

120 |

120 |

160 |

120 |

160 |

|

200 |

240 |

|||

|

Partial conveying angle conveying capacity Q3/h |

30° |

15 |

14 |

20 |

34 |

46 |

71 |

10 4 |

120 |

128 |

157 |

|

195 |

235 |

||

|

45° |

11 |

10 |

14 |

26 |

35 |

57 |

83 |

97 |

102 |

127 |

|

157 |

195 |

|||

|

60° |

8 |

7 |

10 |

18 |

25 |

40 |

58 |

69 |

72 |

90 |

|

112 |

142 |

|||

|

90° |

4 |

4 |

5 |

10 |

13 |

21 |

31 |

37 |

38 |

48 |

|

60 |

76 |

|||

|

Dimensions |

Head wheel center height H2/h (MM) |

350-100 |

1100-2000 |

1300-2000 |

1300-2000 |

|||||||||||

|

Tail wheel center height H2/h (MM) |

335 |

330-490 |

600 |

600 |

600-800 |

|||||||||||

|

Middle section belt surface height H2/h (MM) |

450 |

500-700 |

760-800 |

800-850 |

800-1115 |

|||||||||||

|

Middle section foot width B2/h (MM) |

480 |

580 |

870 |

1020 |

1220 |

|||||||||||

|

Belt width B (mm) |

1000 |

1200 |

1400 |

|

||||||||||||

|

Sidewall height (mm) |

120 |

160 |

200 |

240 |

160 |

200 |

240 |

300 |

160 |

200 |

240 |

300 |

400 |

|||

|

Partial conveying angle conveying capacity Q3/h |

30° |

172 |

216 |

267 |

327 |

275 |

331 |

419 |

466 |

31 9 |

395 |

500 |

564 |

794 |

||

|

45° |

137 |

175 |

216 |

271 |

222 |

267 |

347 |

384 |

258 |

318 |

414 |

465 |

680 |

|||

|

60° |

96 |

124 |

153 |

197 |

158 |

190 |

253 |

178 |

184 |

226 |

302 |

337 |

524 |

|||

|

90° |

51 |

66 |

83 |

106 |

85 |

102 |

136 |

149 |

98 |

121 |

162 |

180 |

281 |

|||

|

External dimensions |

Head wheel center height H2/h (MM) |

1400-2000 |

1600-2000 |

|||||||||||||

|

Tail wheel center height H2/h (MM) |

600-800 |

800-1000 |

800-1200 |

|||||||||||||

|

Middle section belt surface height H2/h (MM) |

800-1200 |

1050-1500 |

1050-1700 |

|||||||||||||

|

Middle section foot width B2/h (MM) |

1440 |

1690 |

1890 |

|||||||||||||

Mesh size of belt conveyor corn

|

Description |

Approximate particle size range (mm) |

Corresponding mesh size of screen |

Sieve size (mm) |

Remarks |

|

Material directly handled by belt conveyor |

Typical corn kernel range: about 5-12 mm |

-(no direct mesh number correspondence) |

- |

Belt conveyor handles formed corn kernels |

|

Smallest debris/impurities that can pass |

<1mm |

About 18 mesh or higher |

<1.0 |

These are fine impurities that may need to be screened out before or after conveying |

|

Small grain corn or broken kernels |

About 1-4.75mm |

About 4 mesh or higher |

1.0-4.75 |

These are particles that are smaller than whole kernels and may pass through larger screens |

|

Standard corn kernels |

About 4.75-12mm |

Usually intercepted by 4 mesh or larger sieves |

>4.75 |

Belt conveyors mainly transport materials in this size range |

|

Large corn kernels |

about 8.00-12mm |

Usually intercepted by 2.5 mesh or larger sieves |

>8.00 |

Large corn varieties or kernels |

|

Extra large particles/debris |

>12mm |

Usually intercepted by sieves smaller than 1.5 mesh or coarser |

>12.5 |

May contain corn cob fragments or other debris that needs to be removed by coarse screening |

Application of belt conveyor corn

Belt conveyor corn is widely used in corn production, processing, warehousing and other links. The following are some specific application scenarios:

Corn harvesting site: In large-scale corn planting farms, after the combine harvester harvests corn in the field, it can directly transport the corn to the corn belt conveyor. Belt conveyor corn transports corn from the harvester to the transport vehicle at the end of the field, realizing the rapid collection and transportation of corn, reducing the workload and time of manual handling.

Corn drying plant: Corn harvested from the field usually contains a certain amount of moisture and needs to be dried. The corn belt conveyor transports the wet corn from the feed port to the dryer, and the dried corn is then transported to the storage area or the next processing step through the belt conveyor. During the drying process, the belt conveyor corn can ensure uniform drying effect according to the working rhythm of the dryer.

Corn processing plant: In the raw material pretreatment workshop, it can unload the transported corn and transport it to the cleaning equipment to remove impurities and soil; then the cleaned corn is transported to the crusher, grinder and other processing equipment for further processing. In the deep processing of corn, such as the production of corn starch, corn protein powder, corn oil and other products, the belt conveyor is used to transport corn raw materials and intermediate products between various production links.

Corn storage logistics: In the corn warehouse, the belt conveyor corn is used to transport corn from the transport vehicle to the designated storage location in the warehouse, or to transport corn in the warehouse to the outbound vehicle. By rationally arranging the belt conveyor system, efficient loading and unloading and stacking of corn can be achieved, and the space utilization rate and cargo turnover efficiency of the warehouse can be improved.