Corn belt conveyor

Corn belt conveyor is a continuous conveying equipment specially used for conveying corn or other granular crops. It is widely used in agriculture, grain processing, warehousing and logistics and other fields.

Screening mesh: 10-60 mesh, accuracy of more than 95%

Processing capacity: 10-50 tons/hour

Conveying mode: support horizontal or inclined conveying (≤25°)

Conveying parameters: belt width 500-1000mm, belt speed 0.8-2.5m/s

What is corn belt conveyor?

Corn belt conveyor is a high-efficiency equipment designed for grain transportation, widely used in farms, grain depots and processing plants. The equipment uses wear-resistant conveyor belts, with optional conveying widths of 500mm, 650mm, and 800mm, and a customizable conveying length of 3-20 meters, and an adjustable conveying angle (0-30°). The belt running speed is generally 0.8-2.5m/s, which can be adjusted according to demand. The screening function can be equipped with a screen, and the screening mesh can be selected as 10 mesh, 20 mesh, and 30 mesh, which can effectively remove impurities and improve the purity of corn. It is widely used in grain storage, deep processing production lines and other scenarios.

Classification of corn belt conveyor

|

Classification |

Picture |

Features |

Applicable scenarios |

Screening mesh |

Conveying capacity |

Bandwidth |

|

Fixed type |

|

Requires installation with anchor bolts, high stability, suitable for long-term use |

Grain processing plant, fixed production line |

20-60 mesh |

50-3000t/h |

500-1200mm |

|

Mobile type |

|

With wheels or foldable, equipped with lifting device |

Grain silo loading, open yard, temporary transfer |

20-80 mesh |

30-500t/h |

500-800mm |

|

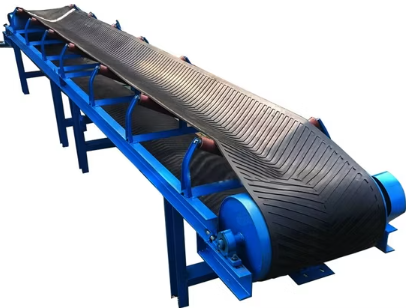

Large inclination type |

|

Supports larger inclination angle (<30°),long-distance transportation |

Complex terrain, port terminal |

20-60 mesh |

100-2000t/h |

600-1200mm |

|

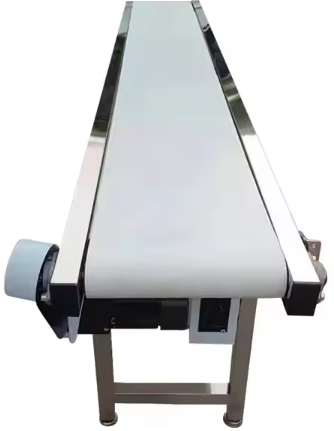

Sealed type |

|

Fully enclosed design to reduce dust |

Processing plant, storage |

20-80 mesh |

50-1000t/h |

500-1000mm |

Video of corn belt conveyor

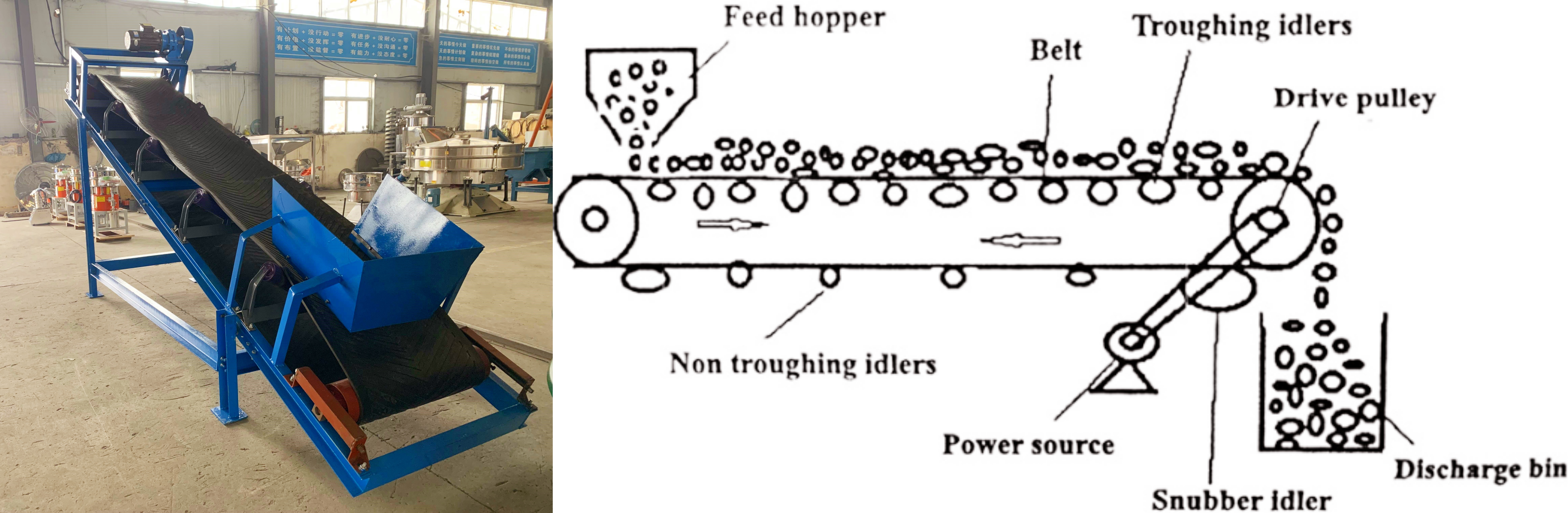

What is the working principle of corn belt conveyor?

The motor (or diesel engine) drives the conveyor belt roller to rotate through the reducer. The corn grains are placed on the belt, and as the belt runs continuously, they are smoothly sent from the feed end to the discharge end. There are rollers under the belt to prevent the belt from sagging, while reducing friction and ensuring smooth operation. The belt is adjusted to be tight by the tensioning device (screw type or weight type) to avoid slipping or deviation. If there is a screening device, the corn can also filter out impurities through the screen during the transportation process to achieve the cleaning effect.

In summary, the working principle of the corn belt conveyor can be summarized as follows:

Motor → reducer → active roller rotation → friction drives the conveyor belt to move → conveyor belt carries corn → roller support → tensioning device maintains tension → guide device prevents deviation → continuous delivery of corn to the unloading point.

This continuous delivery method makes the corn delivery efficiency high, the delivery volume large, and the damage to the corn small. Through reasonable design and selection of conveyor belts, drive devices and other components, the corn delivery needs under different working conditions can be met.

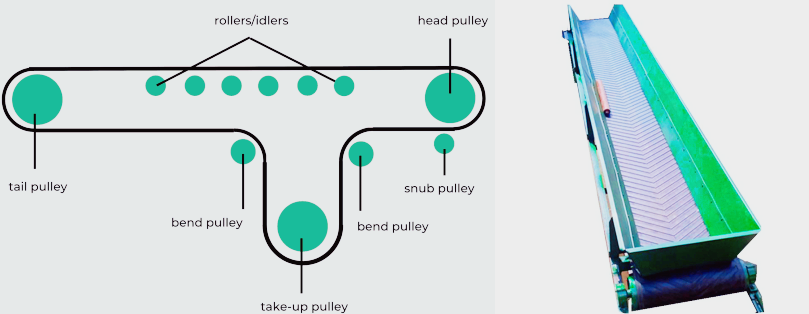

Basic components of corn belt conveyor

Drive device: The motor or diesel engine provides power and drives the roller to rotate through the reducer.

Conveyor belt: Made of wear-resistant and non-slip rubber or PVC material, the surface can be designed with non-slip patterns to adapt to the characteristics of corn.

Rollers and rollers: The driving roller transmits power, the reversing roller adjusts the direction, and the roller supports the conveyor belt and reduces friction.

Frame: Steel structure or aluminum profile frame, supporting the overall structure, can be designed as fixed or mobile.

Tensioning device: Adjust the tightness of the conveyor belt to prevent slipping or deviation.

What are the advantages of corn belt conveyor

During the corn transportation process, there are indeed many problems and challenges. The corn belt conveyor can effectively solve these problems through its ingenious design and diversified configuration, ensuring the efficient and safe transportation of corn.

① Dealing with the problem of corn scattering and waste

Bulk corn kernels are easily scattered due to vibration, wind and other factors during transportation, causing waste and environmental pollution. The corn belt conveyor is equipped with corrugated sidewalls to further improve the lateral restraint of the conveyor belt, which is especially suitable for conveying at large angles and effectively prevents materials from rolling down.

② Solve the problem of insufficient conveying capacity

When production demand increases, traditional conveying methods may not be able to meet the needs of large-scale corn conveying. Increase the cross-sectional area of the conveyor belt to increase the single conveying volume. Under the premise of ensuring the stability of the material, appropriately increase the running speed of the conveyor belt. For the demand for ultra-large conveying volume, multiple belt conveyors can be used to work simultaneously.

③ Solve the problem of damage during transportation

Especially for more fragile materials such as corn cobs, extrusion and collision during transportation may cause damage. Use rubber or PVC conveyor belts with good elasticity to reduce impact, avoid material accumulation and extrusion caused by sudden stop and start, ensure smooth transition between conveyor sections, and reduce material rolling and collision.

④ Deal with the problem of impurities mixing and affecting subsequent processing

Harvested corn is often mixed with impurities such as soil, straw, and stones, which affect the subsequent processing quality and equipment operation. Integrate a screening net on the belt conveyor to simultaneously remove impurities of different sizes during transportation and improve the purity of corn.

Technical parameters of corn belt conveyor

|

Parameters |

Description |

|

Conveying capacity |

30-3000 t/h (adjusted according to model and bandwidth) |

|

Bandwidth |

500-1200 mm (common specifications, some can be customized) |

|

Conveying speed |

0.8-3.15 m/s (adjustable by inverter) |

|

Conveying length |

5-1000 m (supports customization, depending on terrain and model) |

|

Conveying inclination |

0-30° (large inclination model supports higher angle) |

|

Material temperature |

≤60℃ |

|

Material bulk density |

≤1.67 t/m³ |

|

Screening mesh |

20-80 mesh (optional screening device) |

|

Drive power |

1.5-75 kW (depending on the conveying volume and length) |

|

Conveyor belt material |

rubber, PVC or steel wire rope core (wear-resistant and corrosion-resistant) |

|

Power supply |

220V/380V (mobile small equipment supports 220V) |

|

Working environment temperature |

-20℃ to +40℃ |

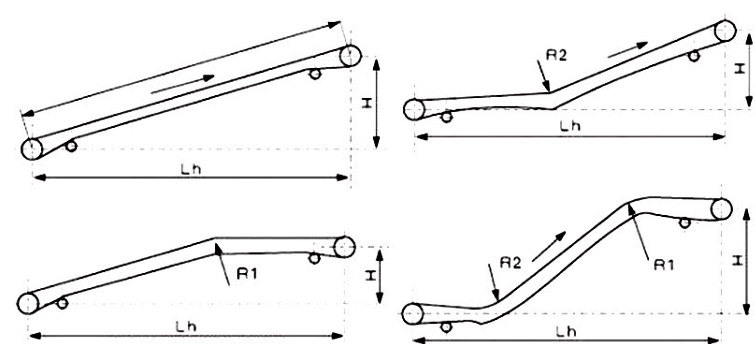

Layout of corn belt conveyor

The construction form of corn belt conveyor usually includes a combination of upper horizontal section, lower horizontal section and inclined section according to pipeline transportation and site requirements. The construction operations of these sections are varied and adapted to different pipeline scenarios, such as grain silo loading and unloading, processing production lines or complex transportation.

① Upper horizontal section (upward conveying section)

Location: Usually located at the discharge end of the conveyor, it may also be used to raise materials or change the conveying direction.

Function: The material is lifted to a higher height by the belt in the upward conveying section, and is usually used to transport materials to a high place.

Features: The conveyor belt will have a certain rising angle to ensure that the corn can move upward smoothly under the action of gravity. Since gravity needs to be overcome, the motor power and drive system are required to have a certain driving force.

② Lower horizontal section (downward conveying section)

Position: Usually used at the feed end of the conveyor, and can also be used as the part for conveying falling materials.

Function: The material flows by gravity in the downward conveying section, reducing power consumption, which is suitable for conveying materials to low places.

Features: The conveyor belt is almost parallel to the ground, and the belt runs at a faster speed to ensure that the corn moves quickly. Due to the effect of gravity, the equipment consumes less electricity, which is conducive to energy saving.

③ Inclined section (slope conveying section)

Position: Connect the upper horizontal section and the lower horizontal section, or use it as an inclined conveying section to adapt to different terrains.

Function: The inclined section is used to change the conveying direction or height, especially suitable for conveying tasks with height differences, and is often used for stacking, loading and unloading and other operations.

Features: The conveyor belt is sloped in this section. According to the required inclination angle, the angle of the conveyor belt can be adjusted (generally between 0° and 30°). This section needs to provide a stronger driving force to ensure that the corn can be smoothly conveyed at an inclined angle.

Application of corn belt conveyor

Post-harvest corn transportation on the farm: After the harvest on the farm, corn needs to be transported from the field to the storage or processing area. Due to the poor road conditions in the field, the traditional manual handling is inefficient and easy to damage the corn. The mobile belt conveyor is used to facilitate flexible movement between different locations. The belt design ensures that the corn is not easily damaged during transportation and maintains the integrity of the corn.

Corn transportation in grain processing plants: Corn from the receiving area to each process such as grinding, peeling, and screening requires an efficient conveying system. The upper and lower horizontal sections of the conveyor can transport corn from one processing link to another. The adjustable speed belt conveyor can adjust the conveying speed according to the needs of different processes to ensure the smooth processing process.

Food processing and corn product production: Before corn is processed into various foods (such as corn flakes, corn flour, corn starch, etc.), it needs to be processed by conveying equipment. The upward conveying section can send corn to pre-treatment equipment such as peeling and cleaning. The conveyor can evenly distribute corn to each processing link.

Corn loading and unloading: During the corn wholesale and transportation process, corn needs to be transported from the warehouse to the transport vehicle (such as trucks, containers, etc.). The conveyor with adjustable inclination angle can adjust the angle according to the transport vehicles of different heights to ensure accurate and fast loading of corn.

Corn deep processing: In the corn deep processing production line, corn needs to be transported to the extraction equipment for subsequent processing, such as extracting corn starch, corn oil, etc. The corn belt conveyor can transport corn from the storage area to the processing area to meet different production needs.