Two Conveyors For Powder

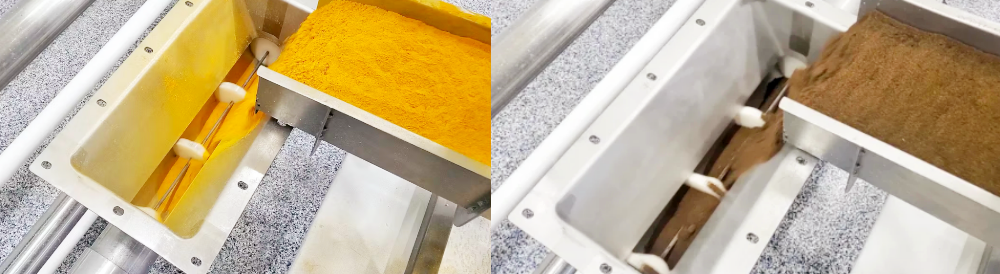

Two conveyors for powder are designed for powder materials (such as flour, chemical powder), suitable for flour mills, feed processing, chemical production lines and other scenarios.

Conveyor belt material: anti-stick PU/PVC material

Width: 100-300mm

Speed: 0.5-1.5m/s

Conveying capacity: 20-100kg/h

What are two conveyors for powder?

Two conveyors for powder work together to achieve efficient and fine powder processing. The first conveyor is a pneumatic conveying system, which is responsible for delivering raw material powder with an average particle size of 50 microns from the storage tank to the feed port of the vibrating screen at a conveying rate of 500 kg/hour. The conveying process adopts a fully enclosed design to effectively prevent dust leakage. The second conveyor is a small screw conveyor, which is installed below the discharge port of the vibrating screen. It is responsible for receiving qualified powder after 80 mesh fine screening and conveying it to the mixing equipment at the rear end at a rate of 400 kg/hour. This system effectively combines conveying efficiency and screening accuracy, and is suitable for production links with high requirements for powder purity and particle size.

Comparison of core types of powder conveyors

|

Comparison dimensions |

Pneumatic conveyor |

Screw conveyor (auger) |

Belt conveyor (for powder only) |

|

Image |

|

|

|

|

Conveying principle |

Use compressed air or vacuum to suck powder |

The spiral blade rotates to push the powder to move axially |

The friction of the belt drives the powder to be conveyed horizontally/inclined |

|

Applicable scenarios |

Long distance, large batch, easy to dust powder (such as flour, plastic particles) |

Short distance, sticky powder (such as putty powder, feed) |

Medium and short distance, light powder (such as milk powder, medicine powder) |

|

Sealing |

Fully enclosed pipeline, no leakage |

Semi-enclosed, dust cover needs to be installed |

Open or semi-enclosed, dust removal device is required for easy dust |

|

Energy consumption |

High (need air compressor) |

Low (motor direct drive) |

Medium (depends on the drive mode) |

|

Maintenance cost |

Filter element needs to be replaced regularly, system is complex |

Simple structure, easy to clean |

Belt needs to be replaced regularly, roller needs to be lubricated |

About the application ideas of two conveyors for powder

①Use in series: The two conveyors for powder may be connected end to end for longer distance transportation, or perform different operations during transportation (for example, the first one is used for lifting and the second one is used for horizontal transportation). Extend the transportation distance or realize multiple sections of transportation at different heights and angles.

②Use in parallel: The two conveyors may be used to transport powder from the same or different sources to different destinations, or to handle different types of powders, increase the conveying volume or handle different materials.

③Segment control: With the intelligent control system, the conveying status of each section is monitored by sensors to achieve automatic start and stop, optimize energy use and transportation efficiency.

Video of two conveyors for powder

What is the working principle of two conveyors for powder?

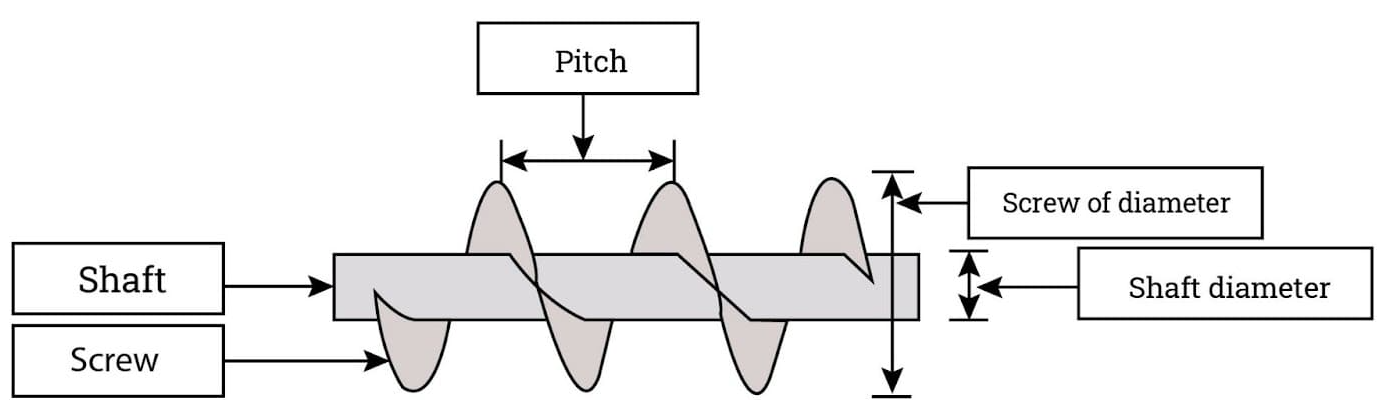

Screw conveyor:

Screw conveyor is a machine that uses rotating spiral blades to push powdered materials in a trough for conveying.

Feeding: Powder enters the trough from the feed port.

Conveying: The spiral blades on the motor drive shaft rotate, and the friction between the blades and the trough wall prevents the powder from rotating with the blades, so that the powder moves forward along the direction of the spiral axis.

Discharging: The powder is pushed to the discharge port for discharge.

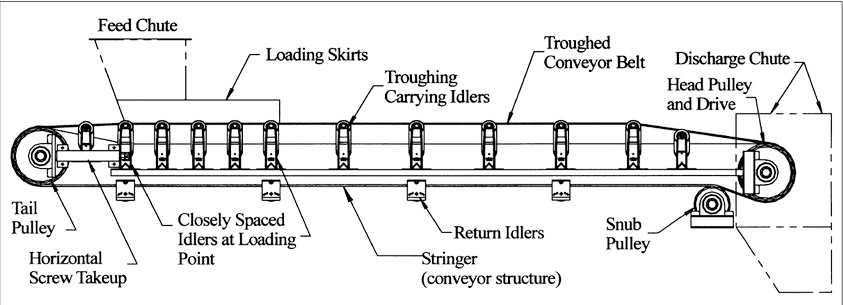

Belt conveyor (often with special designs for powders)

Although belt conveyors are more commonly used for granular or block materials, specially designed belt conveyors can also convey powders. For example, adding skirts to prevent scattering, or using special belt materials.

Working process: Similar to ordinary belt conveyors, the motor drives the roller to drive the endless belt to move, and the powder is placed on the belt and moves to the discharge point.

When two conveyors for powder are used together, their working principles still follow the characteristics of their types, but they are coordinated according to the process flow:

Series: The first conveyor conveys the powder to the feed port of the second conveyor, achieving longer distance conveying or lifting at different heights.

Parallel: The two conveyors for powder may simultaneously convey different powders from different sources to the same mixing equipment, or convey the same powder to different destinations.

Combination: For example, one pneumatic conveyor is responsible for conveying raw powder to the intermediate silo over a long distance, and the other screw conveyor is responsible for accurately feeding the powder from the intermediate silo to the production equipment.

Features of two conveyors for powder

The two conveyors for powder have outstanding features in powder material transportation and are designed for efficient, flexible and clean transportation. The following are its main features, combined with powder characteristics and collaborative work requirements:

Lightweight and flexible: Each weighs 30-50kg, equipped with mobile wheels or folding structure, easy to carry and store, suitable for small workshops, flour mills, chemical production lines and other space-constrained scenes.

Powder adaptation: The conveyor belt is made of anti-stick and anti-slip PU/PVC material, with a width of 100-300mm, a speed of 0.5-1.5m/s, and a conveying capacity of 20-100kg/h, which is suitable for fine powders (such as flour, talcum powder, particle size 50-120 mesh). Optional dust cover or sealing groove to reduce dust flying.

Screening function: At least one is equipped with a screening device with a mesh size of 50-120 mesh, which can filter impurities or grade powder to ensure material quality, especially suitable for feed or chemical powder processing.

Collaborative and efficient: Two units can be connected in series (extending the conveying distance by 5-10m) or in parallel (diverting to multiple lines), supporting inclined conveying (0-30°), and flexible layout. The motor power is 0.5-1kW, energy-saving and stable.

Easy to operate and maintain: variable frequency speed regulation, adjustable height, easy to operate. The quick release mechanism is easy to disassemble and assemble, the conveyor belt is wear-resistant and easy to clean, and the maintenance cost is low.

High cost performance: The price of a single unit is 5,000-20,000 yuan, with powerful functions, suitable for small enterprises, and fast return on investment.

These features enable the conveyors to work together efficiently in powder transportation and meet diverse needs.

Technical parameters of two conveyors for powder

|

LS type |

100 |

160 |

200 |

250 |

315 |

400 |

500 |

630 |

800 |

1000 |

1250 |

|

GX type |

|

|

200 |

250 |

300 |

400 |

500 |

|

|

|

|

|

Screw diameter (mm) |

100 |

160 |

200 |

250 |

315 |

400 |

500 |

630 |

800 |

1000 |

1250 |

|

BE (mm) |

100 |

160 |

200 |

250 |

315 |

355 |

400 |

450 |

500 |

560 |

630 |

|

Speed(r/min) |

140 |

120 |

90 |

90 |

75 |

75 |

60 |

60 |

45 |

35 |

30 |

|

Conveying capacity QΦ=0.33 (m3/h) |

2.2 |

7.6 |

11 |

22 |

36.4 |

66.1 |

93.1 |

160 |

223 |

304 |

458 |

|

Power Pd 1=10m (KW) |

1.1 |

1.5 |

2.2 |

2.4 |

3.2 |

5.1 |

4.1 |

8.6 |

12 |

16 |

24.4 |

|

Power Pd 1=30m (KW) |

1.6 |

2.8 |

3.2 |

5.3 |

8.4 |

11 |

15.3 |

25.9 |

36 |

48 |

73.3 |

|

Speed (r/min) |

120 |

90 |

75 |

75 |

60 |

60 |

45 |

45 |

35 |

30 |

20 |

|

Conveying capacity QΦ=0.33 (m3/h) |

1.9 |

5.7 |

18 |

18 |

29.1 |

52.9 |

69.8 |

125 |

174 |

261 |

305 |

|

Power Pd 1=10m (KW) |

1.0 |

1.3 |

2.1 |

2.1 |

2.9 |

4.1 |

4.7 |

6.8 |

9.4 |

14.1 |

16.5 |

|

Power Pd 1=30m (KW) |

1.5 |

2.3 |

4.5 |

4.5 |

7 |

8.9 |

11.6 |

20.4 |

28.3 |

42.2 |

49.5 |

|

Speed (r/min) |

90 |

75 |

60 |

60 |

45 |

45 |

35 |

35 |

30 |

20 |

16 |

|

Conveying capacity QΦ=0.33 (m3/h) |

1.4 |

4.8 |

15 |

15 |

21.8 |

39.6 |

54.3 |

97 |

149 |

174 |

244 |

|

Power Pd 1=10m (KW) |

0.9 |

1.2 |

1.9 |

1.9 |

2.5 |

3.4 |

4.3 |

5.4 |

8.1 |

9.5 |

13.3 |

|

Power Pd 1=30m (KW) |

1.2 |

2.2 |

3.8 |

3.8 |

5.4 |

6.8 |

9.2 |

16 |

24.4 |

28.6 |

39.9 |

|

Speed (r/min) |

75 |

60 |

45 |

45 |

35 |

35 |

30 |

30 |

20 |

16 |

13 |

|

Conveying capacity QΦ=0.33 (m3/h) |

1.2 |

3.8 |

11 |

11 |

17 |

31.7 |

46.5 |

73.0 |

99.3 |

139 |

199 |

|

Power Pd 1=10m (KW) |

0.75 |

1.1 |

1.6 |

1.6 |

2.1 |

3.1 |

3.7 |

4.6 |

5.7 |

7.7 |

11 |

|

Power Pd 1=30m (KW) |

1.1 |

1.8 |

3.4 |

3.4 |

4.4 |

5.6 |

|

14 |

16.7 |

23.2 |

33 |

Application of two conveyors for powder

Building materials production line: After the cement powder comes out of the mill, it is horizontally conveyed to the temporary storage bin by the first screw conveyor, and then tilted and lifted to the mixer entrance by the second screw conveyor. In gypsum powder production, one conveyor transports gypsum powder from the dryer outlet to the finished product bin, and the other conveyor transports the finished gypsum powder to the bagging machine.

Food processing plant: In the flour production workshop, one conveyor transports flour from the storage bin to the screening machine, and after screening, another conveyor transports qualified flour to the packaging machine. Soybean powder and corn flour are sent to different formula areas through two conveyor lines for feed mixing pretreatment.

Chemical plant: Different types of chemical powders (such as zinc oxide powder and calcium carbonate powder) are transported to different mixing reactors in parallel through two conveyors for powder.

Battery material factory: conveying lithium battery positive electrode material powder (such as lithium iron phosphate powder), one conveyor is conveyed to the mixer, and the other conveyor is conveyed to the metering system to ensure synchronous feeding of different processes.

Pharmaceutical manufacturing plant: conveying the drug powder to the front end of the tablet press through a vacuum conveyor. The first conveyor is responsible for feeding the raw materials, and the second conveyor is responsible for accurate feeding after screening.

Paint factory: titanium dioxide, carbon black powder and other pigment powders are supplied to different colors of paint mixing tanks through two independently controlled conveyors.

Supplier of the two conveyors for powder

Dahan Machinery is a well-known powder conveying equipment supplier in China, focusing on vibration screening and conveying equipment manufacturing, suitable for powder material processing.

① Equipment type: Dahan Machinery provides small belt conveyors, suitable for powder materials (such as flour, chemical powder, particle size 50-120 mesh). Micro or mobile models are recommended, the conveyor belt is made of anti-stick PU/PVC material, width 100-300mm, conveying capacity 20-100kg/h, speed 0.5-1.5m/s.

② Collaborative design: two units can be connected in series (extended distance 5-10m) or in parallel (diverted to multiple lines), support inclined conveying (0-30°), and flexibly adapt to the layout of the production line.

③ Portable and clean: Each unit weighs 30-50kg, equipped with mobile wheels, motor power 0.5-1kW, energy-saving and portable. Equipped with a dust cover to reduce powder flying and meet hygiene standards.

④ Easy to maintain: quick disassembly and assembly design, the conveyor belt is wear-resistant and easy to clean, and the maintenance cost is low.

Contact information: You can consult through Dahan’s official website (www.dahanmachine.com) or email (My whatsapp: +86 15236742901, e-mail: sale@xxdahan.com) to obtain quotes and technical support.