Belt Conveyor Limestone

Belt conveyor limestone is a machine that uses a conveyor belt as a traction and load-bearing component, and drives the conveyor belt to run through a drive device, thereby continuously conveying limestone bulk or block materials. It plays an important role in the mining, processing and utilization of limestone.Conveying capacity: up to 1000 tons/hour or more, depending on the belt width and conveying speed

Common specifications of belt width: 500mm, 650mm, 800mm, 1000mm, etc.

Inclination angle: usually between 0° and 18°, and a corrugated sidewall belt conveyor is required when it exceeds this range

Belt speed: 0.8~2.5 m/s

What is a belt conveyor limestone?

Limestone is a medium-hard and heavy sedimentary rock with a Mohs hardness of generally between 3-4, a density of about 2.7-2.9g/cm³, and a block size of large or small. During transportation, limestone is prone to dust, and some fragments are angular, which may cause wear on the conveyor belt. Therefore, belt conveyors usually use wear-resistant rubber conveyor belts to extend the service life of the equipment.

Belt conveyor limestone is a continuous conveying equipment dedicated to conveying limestone materials. It is widely used in mining, building materials, cement, metallurgy, electric power and other industries to transport limestone from the collection point or crushing workshop to the storage bin, screening equipment or further processing. Its main structure consists of a conveyor belt, a drive device, rollers, a frame, a redirection device and a tensioning device. It has the characteristics of high conveying efficiency, stable operation and easy maintenance.

Classification of belt conveyor limestone

|

Classification dimension |

small conveyor |

medium conveyor |

large conveyor |

|

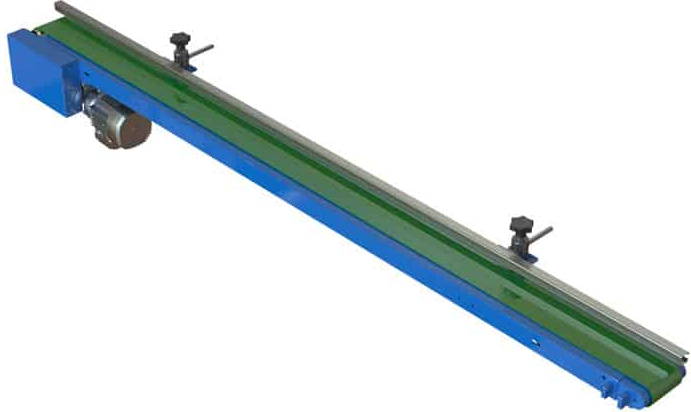

Picture |

|

|

|

|

Conveying capacity |

tens of tons/hour |

100-500 tons/hour |

more than 500 tons/hour |

|

Conveying speed |

0.5-1.0 m/s |

1.0-2.0 m/s |

more than 2.0 m/s |

|

Applicable materials |

powdered or fine-grained limestone |

granular limestone |

large block limestone |

|

Application range |

small-scale operation, local transportation |

medium-scale mines, cement plants |

large mines, cement plants, power plants |

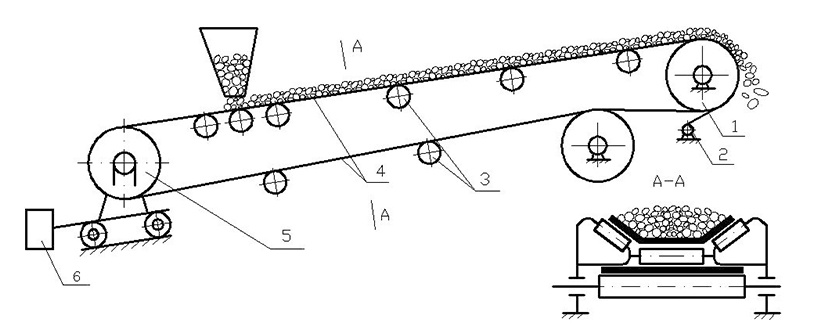

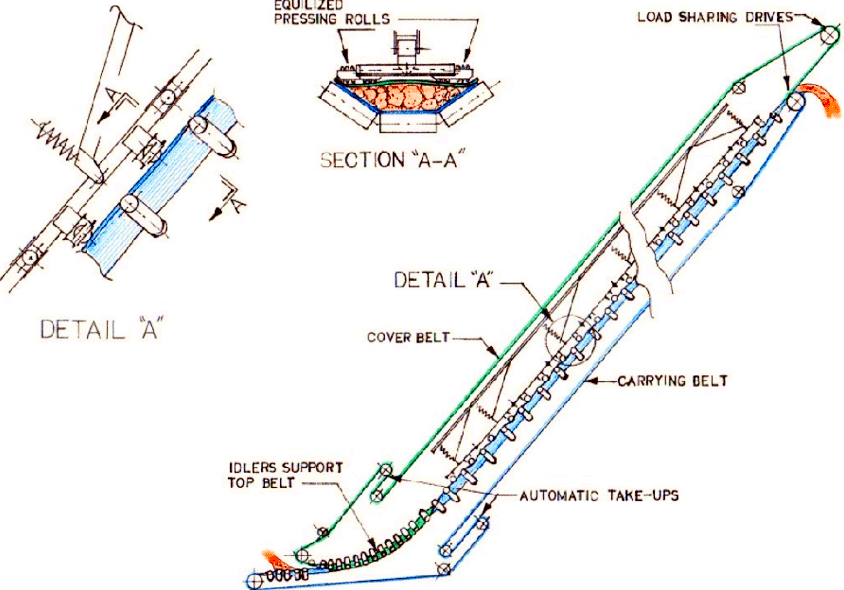

Working principle of belt conveyor limestone

Belt conveyor limestone realizes continuous material transportation through the friction between the ring belt and the driving roller, which is especially suitable for medium and long-distance transportation of block, powder and mixed limestone. The motor drives the roller to rotate, driving the belt to circulate, and uses the friction between the belt and the material to realize horizontal or inclined transportation of limestone. According to the working conditions, accessories such as baffles, skirts, and sealing covers can be configured to prevent material spillage or dust.

The structure of belt conveyor limestone

The belt conveyor limestone is mainly composed of the following parts:

Conveyor belt: the main component for carrying and conveying materials, usually made of rubber, canvas, wire rope and other materials.

Drive device: including motor, reducer, coupling, etc., to provide power for the operation of the conveyor belt.

Drive roller and redirecting roller: used to drive and change the running direction of the conveyor belt.

Roller: support the conveyor belt, reduce running resistance, and maintain the normal operation of the conveyor belt.

Frame: metal structure that supports and fixes various components of the conveyor.

Tensioning device: provide appropriate tension for the conveyor belt, ensure the friction between the conveyor belt and the roller, and prevent slipping.

Safety protection device: such as deviation switch, emergency stop switch, overload protection, etc., to ensure the safe operation of the conveyor.

Advantages of belt conveyor limestone

①Solve the difficulty of material accumulation and cleaning in the return section: choose a conveyor belt with self-cleaning function: for example, a conveyor belt with a scraper, protrusion or special texture to enhance the scraping effect of adhered materials. Reasonable tension helps reduce the retention of materials on the belt surface. Compared with mechanical joints, vulcanized joints have a smoother surface, reducing the scraping and adhesion of materials.

② Dealing with accelerated wear of conveyor belts and rollers: Select conveyor belts with high wear-resistant rubber coverings according to the hardness and abrasiveness of limestone. Use rollers with high surface hardness and good wear resistance, such as ceramic rollers, polyurethane rollers or steel rollers with special surface treatment. Reducing the conveying speed can reduce the impact and wear of materials on conveyor belts and rollers to a certain extent.

③ Dealing with the problem of conveyor belt tearing or damage caused by large pieces of limestone: Select conveyor belts with steel wire ropes or high-strength fiber skeletons inside to improve impact and tear resistance. Perform necessary crushing or screening before entering the belt conveyor to control the maximum particle size of the material. Use appropriate chutes and guide plates to reduce the direct impact of large pieces of material on the conveyor belt.

④ Solve the adaptability problem under special environmental conditions (such as high temperature, cold, humidity, etc.): Select conveyor belts that adapt to specific environmental conditions, for example, conveyor belts made of special materials that are resistant to high temperature, cold, and corrosion. Take appropriate protective measures, such as installing antifreeze devices in cold areas and doing anti-rust treatment in humid environments.

Technical specifications of belt conveyor limestone

|

width (mm) |

Conveying length (m)

Power(kw)

|

transfer speed

(m/s)

|

Delivery volume (t/h) |

||

| 400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 | 30-60 |

| 500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 | 40-80 |

| 650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 | 80-120 |

| 800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 | 120-200 |

| 1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 | 200-320 |

| 1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 | 290-480 |

| 1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 | 400-680 |

| 1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 | 600-1080 |

| 1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 | 800-1500 |

| 2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 | 1000-2000 |

| 2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 |

1500-3000 |

Application of belt conveyor limestone

Belt conveyor limestone is widely used in various links of cement production line in building materials industry due to its ability to adapt to different hardness, particle size, potential hygroscopicity and dust characteristics of limestone, such as raw material transportation from crushing workshop to batching station, as well as transportation of clinker, gypsum and other materials; at the same time, in metallurgy, chemical industry, power and other industries, limestone belt conveyor is also often used to transport limestone as desulfurizer or auxiliary raw material, realizing efficient and continuous material transportation, which is an indispensable key equipment in modern industrial production.

Mines: Raw material transportation at limestone mining sites

Cement plants: Limestone transportation from crushers to raw material bins and preheaters

Lime plants: Pre-treatment section for sintering or calcining limestone

Building materials companies: Stone production, mixing station raw material transportation

Metallurgy, electricity: Limestone desulfurization material transportation

A brief description of actual application cases

In a large cement plant, limestone is transported from the mine to the crushing system via a belt conveyor, with a transportation distance of more than 300 meters. Due to the large amount of dust in the transportation process, the company uses a closed belt conveyor and equips the material drop point with a bag dust collector, which effectively reduces the dust concentration in the plant area; at the same time, by using wear-resistant conveyor belts and multi-stage cleaning devices, equipment wear and downtime maintenance times are reduced, ensuring an average annual operating time of more than 95%.

Belt conveyor limestone manufacturer

Xinxiang Dahan Machinery Co., Ltd. is located in Xinxiang City, Henan Province. It is an entity enterprise specializing in the manufacture of bulk material conveying and screening equipment. The company has been established for many years and has relatively mature design, manufacturing and application experience in belt conveyors, screw conveyors, bucket elevators and other fields. For limestone, a highly abrasive and easily pulverized material, Dahan Machinery has certain actual engineering case support.

Structural optimization for limestone conveying:

Limestone has a certain hardness and is easy to generate dust, so the following aspects need to be considered in the design of the belt conveyor:

Belt material: Dahan Machinery's commonly used belt materials include wear-resistant rubber belts and steel cord conveyor belts, which can be selected according to the material temperature and particle size.

Dust-proof design: Sealing covers, spray dust suppression systems, etc. can be added according to customer requirements to help control dust leakage.

Roller and drum specifications: In view of the high specific gravity and strong abrasiveness of limestone, Dahan often uses thickened grooved rollers and heavy-duty drive drums to increase equipment life.

Conveying capacity adaptation: It supports conveying capacity designs from 5t/h to hundreds of t/h, which can be used in small lime kilns, medium-sized limestone crushing lines and other scenarios.

Model customization capability

Dahan Machinery supports non-standard customization and can provide customized services based on customer working parameters (such as conveying distance, height, inclination, material particle size, etc.), covering:

Horizontal and inclined belt conveyors

Movable and fixed structures

Structural adaptation solutions for various working conditions such as ore, limestone, coal, etc.

Customization capability is an advantage of small and medium-sized manufacturers compared to large assembly line companies.

If the user needs to further determine whether to choose Dahan Machinery, it is recommended to obtain the following information for comparison:

Specific engineering cases provided by the manufacturer

Equipment structure drawings and material descriptions

Whether on-site inspection or technical guidance is supported

After-sales service terms (such as warranty period, response time, etc.)

If necessary, I can further help you sort out the technical parameters or application case analysis of the belt conveyor limestone. Do you need it?