Belt Conveyor Seeds

Belt conveyor seeds is a mechanical equipment specially used for conveying seed materials, which is widely used in agriculture, seed processing, warehousing and logistics. Its core function is to transfer seeds from one place to another smoothly and efficiently through a continuously moving conveyor belt, while reducing the breakage rate and maintaining seed quality.

Length: 5 meters, 8 meters, 10 meters, 12 meters, 15 meters, 18 meters, 20 meters, etc.

Conveying capacity: 30-3000 cubic meters/hour

Weighing weight: 1000kg

What is a belt conveyor seeds?

The belt conveyor seeds is a belt conveying equipment specially used for seed conveying in the agricultural field. Its main function is to achieve efficient and smooth conveying operations without destroying the integrity of the seeds. The equipment is widely used in grain processing, seed packaging, warehousing management and other links, and is suitable for the handling and distribution of various crop seeds such as wheat, corn, soybeans, and rice.

What is the purpose of belt conveyor seeds

① Gentle handling: Belt conveyors seeds are the first choice for seed conveying because they minimize the mechanical damage that other types of conveyors, such as screw conveyors or augers, can cause. Maintaining seed viability is critical.

② Efficient transfer: They provide a continuous and high-capacity method for moving seeds between different stages of processing, storage, or loading into the planter.

③ Versatility: belt conveyors can be used for a variety of seed types, from small grains to soybeans.

Types of belt conveyor seeds

|

Type |

Picture |

Features |

Typical application scenarios |

Advantages |

|

Mesh belt belt conveyor seed |

|

Mesh metal or plastic belts are used, which are breathable and corrosion-resistant |

Seed cleaning, drying and grading operations |

Strong ventilation and heat dissipation, suitable for humid environments |

|

Flat belt conveyor seeds |

|

Flat rubber or synthetic material belts |

Suitable for conveying seeds with small particles and good fluidity, such as wheat, rice, rapeseed, etc. |

Used for short-distance transportation and loading and unloading of seeds |

|

Trough belt conveyor seed |

|

The belt has a U-shaped groove structure, which can increase the seed loading capacity and prevent material scattering |

Suitable for conveying seeds with large particles and poor fluidity, such as Corn, soybeans, etc. |

Seed processing and storage links, large conveying capacity |

|

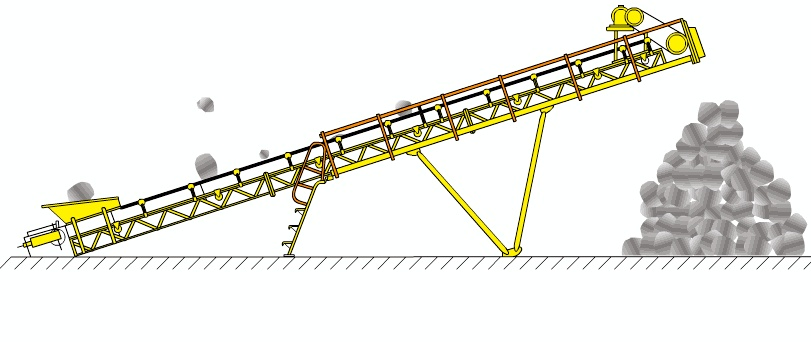

Mobile belt conveyor seeds |

|

Equipped with wheels or brackets, flexible movement |

Temporary loading and unloading on farms, alternating use in multiple sites |

Suitable for temporary conveying and loading and unloading needs of seeds, such as loading grain seed bags, etc. |

|

Telescopic belt conveyor seed |

|

Adjustable conveyor length |

Storage scenes with loading, stacking or space changes |

Flexible adjustment of length, can be used for seed transportation in different sites and different operation requirements |

Video of belt conveyor seeds

Working principle of belt conveyor seeds

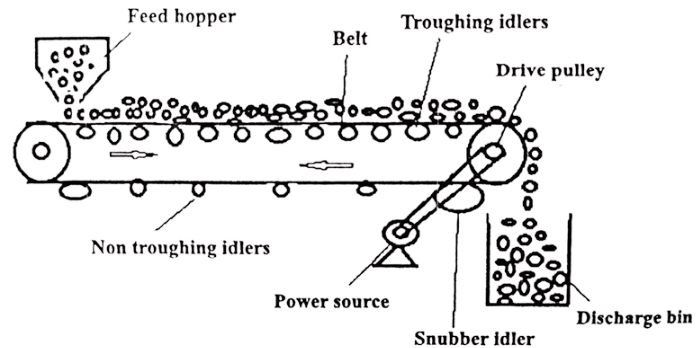

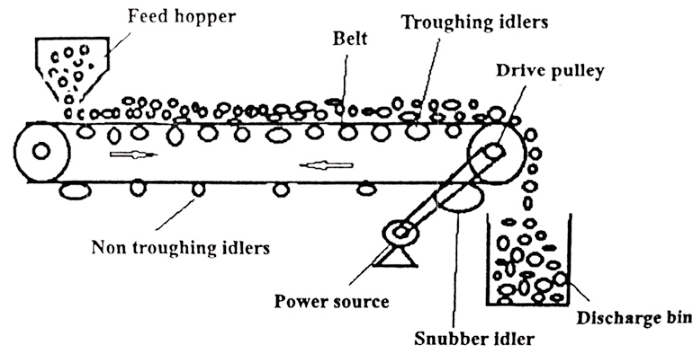

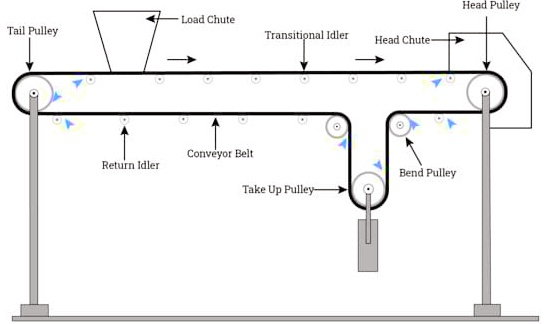

After the drive device of the belt conveyor seeds is started, the drive roller starts to rotate under the action of power, and drives the conveyor belt to move through friction. Place the seeds on the conveyor belt, and the seeds move forward with the belt conveyor seeds under the friction of the conveyor belt, so that they are transported to the designated location. During the transportation process, the roller plays a supporting role to ensure the smooth operation of the conveyor belt and seeds, and the tensioning device adjusts the tension of the belt conveyor seeds at any time to ensure the stability of the transportation process.

Structure of belt conveyor seeds

Conveyor belt: usually made of wear-resistant and corrosion-resistant materials, such as rubber, plastic, etc., to adapt to different working environments and seed characteristics. Some belts conveyor seeds are also equipped with accessories such as anti-slip strips or skirts to prevent seeds from slipping or spilling during transportation.

Drive device: Belt conveyor seeds is generally composed of motor, reducer, coupling, etc., to provide power for the operation of the conveyor belt. By controlling the speed and direction of the motor, the running speed and direction of the conveyor belt can be adjusted.

Roller: used to support the conveyor belt and the seeds on it, reduce the sag and running resistance of the belt conveyor seeds, and ensure the smooth operation of the conveyor belt. Rollers are usually divided into different types such as trough rollers and flat rollers, and are selected according to the conveying requirements.

Roller: including drive roller and redirection roller. The drive roller is connected to the drive device to transmit power to the conveyor belt; the redirection roller is used to change the running direction of the conveyor belt so that the conveyor belt can be turned and transported at different positions.

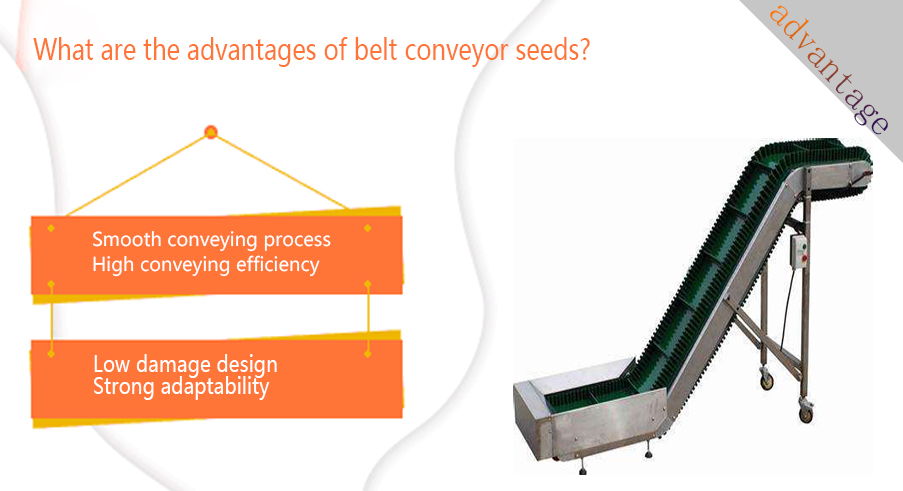

What are the advantages of belt conveyor seeds?

Smooth conveying process: The conveyor belt moves smoothly, and the seeds are not easily subjected to severe vibration and impact during the conveying process, which is conducive to protecting the integrity and germination rate of the seeds.

High conveying efficiency: Seeds can be conveyed continuously, and the conveying speed can be adjusted according to actual needs, which can meet the requirements of large-scale seed processing and transportation.

Low damage design: The surface of the belt conveyor seeds is usually made of anti-slip and anti-static materials (such as rubber, PVC or food-grade plastic) to prevent seeds from being damaged by friction or collision during transportation. The conveying speed is adjustable to adapt to the fragility of different seed types (such as wheat, corn, vegetable seeds, etc.)

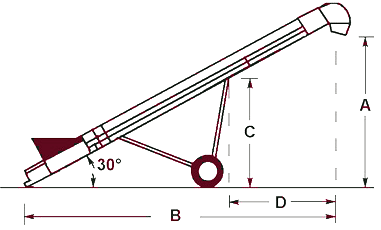

Strong adaptability: Horizontal, inclined or multi-point conveying can be achieved, and the inclination angle generally does not exceed 30° (depending on the fluidity of the seeds). Support customized length and width to meet the needs of different scenarios in warehouses, production lines or fields. The belt conveyor seeds can adapt to the transportation of seeds of different types, different particle sizes and shapes, whether it is small-grained vegetable seeds or large-grained corn seeds, etc., it can be smoothly transported

Technical parameters of belt conveyor seeds

|

Width (mm) |

Conveying length (m) Power (kw) |

Conveying length (m) Power (kw) |

Conveying length (m) Power (kw) |

Conveying speed (m/s) |

Conveying volume (t/h) |

|

400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 |

30-60 |

|

500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 |

40-80 |

|

650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 |

80-120 |

|

800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 |

120-200 |

|

1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 |

200-320 |

|

1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 |

290-480 |

|

1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 |

400-680 |

|

1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 |

600-1080 |

|

1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 |

800-1500 |

|

2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 |

1000-2000 |

|

2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 |

1500-3000 |

Application of belt conveyor seeds

In the process of seed selection, grading, coating, etc., the belt conveyor seeds can transport seeds from one processing equipment to another, realize continuous production and improve processing efficiency. In seed storage, it can be used to transport harvested seeds from the field to the warehouse, or to carry and stack seeds inside the warehouse, which is convenient for seed storage and management. When sowing seeds, the conveyor can also transport seeds from the seed storage to the seeder to achieve precise sowing and ensure the quality and uniformity of seed sowing.

① Loading and unloading in grain depots or seed storage

② Transfer after seed selection and transportation before packaging

③ Seed transportation after cleaning and drying in agricultural processing enterprises

④ Centralized seed transportation and placement before sowing

⑤ Seed transportation in agricultural cooperatives, grain depots, and seed processing plants

Belt conveyor seeds manufacturer

Xinxiang Dahan Machinery Co., Ltd. is a domestic manufacturer specializing in the production of bulk material conveying and screening equipment. Its products cover various types of conveying machinery, including belt conveyors. For applications in agriculture, grain processing and seed processing industries, Dahan Machinery can provide belt conveyor seeds equipment suitable for seed transportation, mainly used for horizontal or small-angle transportation of granular, granular and powder mixed materials, such as wheat, soybeans, corn, rapeseed and other types of crop seeds. The overall structural design focuses on the smooth transportation of materials and the protection of seeds, and is suitable for scenes such as connection and transportation between seed processing workshops and cleaning equipment.