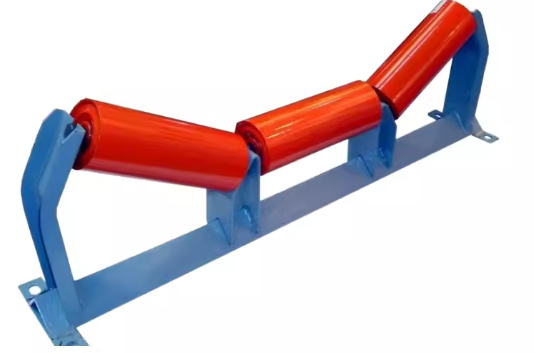

Belt conveyor rollers

Belt conveyor rollers is an important component of the belt conveyor, mainly used to drive the operation of the conveyor belt or transmit the tension of the conveyor belt to the driving device.

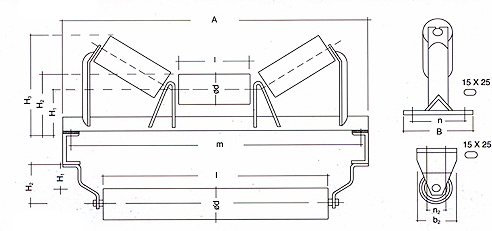

Diameter: Common types include Φ 250mm, Φ 315mm, Φ 400mm, Φ 500mm, Φ 630mm, etc;

Length: Match according to the width of the conveyor belt, usually adding 50-100mm to the width of the belt

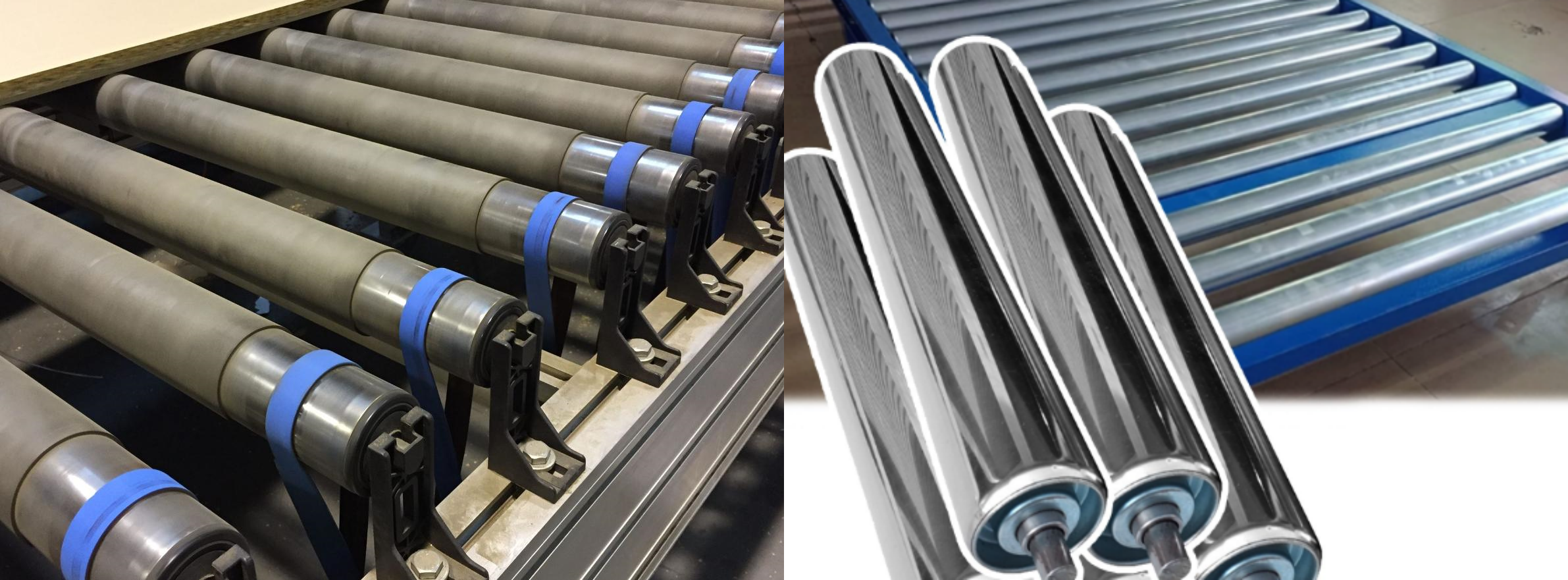

Material selection: stainless steel, carbon steel, aluminum alloy, PVC (polyvinyl chloride), etc

What is a belt conveyor rollers?

Belt conveyor rollers is a key component of the belt conveyor, mainly responsible for transmitting power, changing the direction of belt operation, and ensuring the stable operation of the conveyor. In terms of its characteristics, the material is diverse, stainless steel is corrosion-resistant, and suitable for humid or corrosive environments; Carbon steel has strong load-bearing capacity and low cost, but requires surface treatment; Aluminum alloy is lightweight and commonly used for conveying lightweight materials.

The surface treatment methods are diverse, and the cost of the polished steel surface is low but the friction is small. The coated surface can increase the friction, making it suitable for heavy-duty and anti slip scenarios. Divided by function, it is divided into a transmission rollers and a reversing rollers. The former drives the belt to run, while the latter changes the direction of the belt. The rollers diameter is commonly 500-1000mm, and the bearing capacity is divided into light, medium, and heavy types; The power of the electric rollers is between 2.2-55kw; the speed is related to the belt line speed and can be controlled by adjusting the motor frequency or reducer speed ratio. In addition, the installation methods of the rollers include internal threads, external threads, etc., which need to be selected according to actual needs.

What type of rollers is used for belt conveyors?

Belt conveyor rollers is the core component of the belt conveyor, mainly used to drive the operation of the conveyor belt or transmit the tension of the conveyor belt to the driving device. According to function and structure, rollers can be divided into the following categories:

①Drive rollers (transmission rollers): It is driven by an electric motor to drive the conveyor belt to operate. It is the driving wheel of the conveyor and relies on the friction between it and the conveyor belt to drive the conveyor belt. The driving methods include single rollers, double rollers, and multi rollers. According to the bearing capacity, it can be divided into three types: light, medium, and heavy, with diameters of 500, 630, 800, 1000mm, and other specifications.

②Direction changing rollers (guide rollers): mainly used to change the running direction of the belt. Below the movement of the belt, the structure is similar to that of the transmission rollers, and it is also divided into light, medium, and heavy types according to its bearing capacity. The diameter ranges from 50-100mm, 120-180mm, and 200-260mm. Among them, the surface increasing rollers is generally used in situations where the angle between the belt and the rollers is less than or equal to 45 °, which can increase the friction force.

③ Roller rollers: supports the conveyor belt and the materials on it, prevents the conveyor belt from sagging, and is divided into load-bearing rollers, return rollers, buffer rollers, etc. Maintain the groove or flat shape of the conveyor belt to ensure smooth operation. The idler does not directly drive the belt, but is crucial for the stability and lifespan of the belt.

What is the function of the belt conveyor rollers

Belt conveyor rollers is one of the extremely critical core components in the belt conveyor. It directly carries the belt and materials, drives the belt to run, and guides the belt to change direction. The performance of the rollers directly affects the efficiency, reliability, lifespan, and energy consumption of the conveyor.

Transmission of power: The drive rollers transmits the power of the motor (usually through a reducer) to the conveyor belt through friction, causing it to run.

Changing the running direction: The reversing rollers is used to change the running direction of the conveyor belt (such as 180 °, 90 °, or other angles).

Supporting belts and materials: The supporting rollers of the load-bearing branches support the belts and materials, while the rollers (especially the head and tail rollers) provide the main support at critical turning points.

Increasing the wrap angle: The face increasing rollers (usually located near the drive rollers) is used to increase the wrap angle of the conveyor belt on the drive rollers, thereby increasing friction and improving the transmission capacity of driving force.

Tightening the belt: The tensioning rollers (usually the tail rollers or a reversing rollers in the middle) is part of the belt tensioning device, used to provide and maintain the tension required for the conveyor belt.

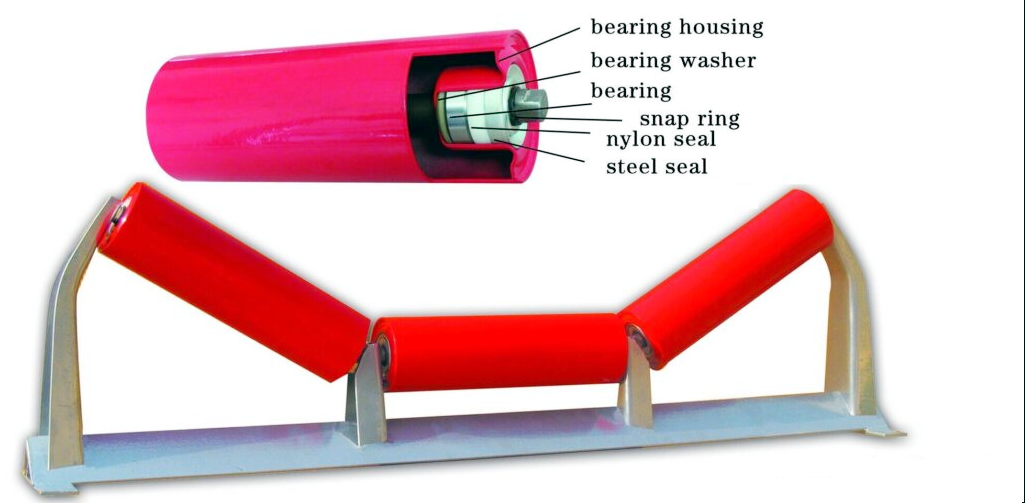

Parts display of belt conveyor rollers

Drum tube: As a carrier, it is the inner ring of rolling bearings, which plays a role in supporting and transmitting power.

Bearing seat: equivalent to the outer ring of a rolling bearing, used to fix the bearing, support the rollers tube, and enable the rollers to rotate stably.

Roller bearings: Connect the roller tube and bearing seat to reduce friction during rotation and ensure smooth rotation of the roller.

Sealing device: prevents dust, rainwater and other debris from entering the interior of the rollers, affecting the normal operation of the rolling bearings and extending the service life of the rollers.

Recommended models of belt conveyor rollers

|

Model |

Drum diameter (mm) |

Drum length (mm) |

Speed range (rpm) |

Applicable scenarios |

|

DT II-159 |

159 |

500-2000 |

10-60 |

Light Conveyor, Food and Electronics Industry |

|

DT II-219 |

219 |

500-3000 |

10-80 |

Medium and light-duty conveying, logistics sorting, etc |

|

DT II-273 |

273 |

600-3000 |

10-90 |

Medium sized Conveyor, Mining and Building Materials Industry |

|

DT II-325 |

325 |

800-3500 |

10-100 |

Heavy duty Conveyor, Coal and Metallurgical Industry |

|

DT II-377 |

377 |

1000-4000 |

10-120 |

Heavy duty Conveyor, Mining and Heavy Industry |

|

DT II-426 |

426 |

1000-4500 |

10-130 |

Special Heavy Duty, Steel and Large Mining Sites |

What is the purpose of the belt conveyor rollers

Belt conveyor rollers plays a crucial role in various material transportation systems, and its main purpose is to ensure the efficient and stable operation of the conveyor belt through functions such as driving, changing direction, and tensioning. Specifically, the driving rollers utilizes the frictional force between the motor or engine and the conveyor belt to transmit the power to the conveyor belt, allowing materials to be transported along a predetermined route. It is widely used in long-distance, high-capacity conveying scenarios for bulk materials such as mines, coal, and ports.

The reversing rollers is used to adjust the direction of the conveyor belt, allowing it to be flexibly arranged in complex layout spaces, such as in logistics sorting centers, where multi angle turning design is used to achieve rapid classification and transfer of packages. The tensioning rollers is responsible for adjusting the tension of the conveyor belt, ensuring that it does not slip due to looseness or cause additional wear due to tightness during operation. This function is particularly important for applications that require constant speed and precise position control, such as continuous production lines in the food processing industry. In short, whether it is horizontal conveying or inclined lifting, the belt conveyor rollers is a key component to ensure the smooth operation of the entire system.

Belt Conveyor Drum Supplier

Dahan Machinery uses high-quality raw materials and strictly controls every step from material selection, processing to assembly. The company can produce various types of belt conveyors and related accessories, such as TD belt conveyors, DY movable belt conveyors, DJ type large angle belt conveyors, mining belt conveyors, expandable belt conveyors, etc. It can meet the different needs of various industries such as food, medicine, chemical, building materials, metallurgy, coal, etc., and can be arranged horizontally or diagonally according to process requirements.

Dahan Machinery has a dedicated technical team that can design according to the needs of users in terms of material conveying, conveying volume, and on-site conditions, ensuring excellent design solutions, short construction periods, and higher cost-effectiveness of similar products. A comprehensive pre-sales, in sales, and after-sales service system can achieve rapid response within 30 minutes, rush to the customer's site for inspection within 72 hours, and provide quick on-site repairs within 24 hours. We also provide free on-site guidance, installation, debugging, and training for users, enabling them to master certain technical knowledge and machine maintenance skills.