Oil resistant belt conveyor

Oil resistant belt conveyor is a conveying equipment specially designed for conveying materials containing various oil substances (such as mineral oil, vegetable oil, animal fat, etc.) or working in oily environments. The conveyor belt made of special oil resistant materials can effectively resist the erosion of grease, lubricants and other chemicals, ensuring long-term stable operation.

Conveyor belt width: 300mm–1200mm

Conveying length: 2m–30m (customizable)

Conveying speed: generally 1.3-2.0 m/s

Conveying capacity: large capacity, continuous or intermittent conveying can be achieved

Versatility: supports multi-point feeding, single-point or multi-point discharging

Applicable materials: suitable for horizontal or inclined conveying of granular, powdered or small block materials below 100kg

Product overview

The oil resistant belt conveyor is a high-efficiency material handling equipment designed for environments containing oil and fat. Its core feature is the use of a specially formulated oil resistant conveyor belt, which can effectively resist the erosion of oil, lubricants and other chemicals, ensuring long-term stable operation without reducing performance.

The conveyor not only has excellent oil resistance, but also has good tensile strength and wear resistance. It can maintain efficient operation under heavy load conditions and is suitable for food processing, chemical production, machinery manufacturing and other industries. The design of oil resistant belt conveyors is flexible and can be customized according to actual needs. Different widths, lengths and speeds can be customized to meet specific production process requirements.

What are the types of oil resistant belt conveyors?

|

Classification dimensions |

Fixed oil resistant belt conveyors |

Mobile oil resistant belt conveyors |

Inclined oil resistant belt conveyors |

|

Picture |

|

|

|

|

Conveying capacity |

Large conveying capacity, suitable for large-scale continuous operations (1000-2000t/h) |

Small conveying capacity, suitable for medium and short distance operations (2-500t/h) |

Conveying capacity depends on the inclination angle and bandwidth, medium to small (4-5m³/h) |

|

Conveying speed |

1.3-2.0 m/s (adjustable) |

1.0-1.8 m/s (adjustable) |

0.8-1.5 m/s (limited by angle) |

|

Structural features |

The frame is fixed, the structure is stable, suitable for continuous operation |

Equipped with wheels or mobile base, flexible movement |

Tilt design, suitable for conveying with height difference |

|

Applicable materials |

Applicable to a variety of oily bulk materials or packaging |

Applicable to light oily packaging or short-distance materials |

Applicable to oily particles/finished products with height difference |

|

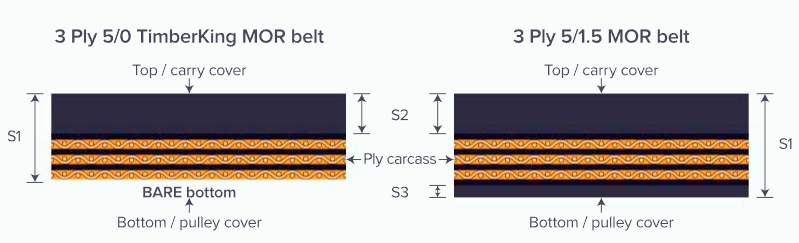

Common belt types |

Oil-resistant rubber belt, PVC, PU |

Light PVC, PU oil resistant conveyor belt |

Skirt baffle belt (oil resistant type) |

|

Application range |

Factory production line, food processing plant, chemical material transportation |

Warehouse, logistics center, temporary workstation |

Food processing lifting, chemical material lifting |

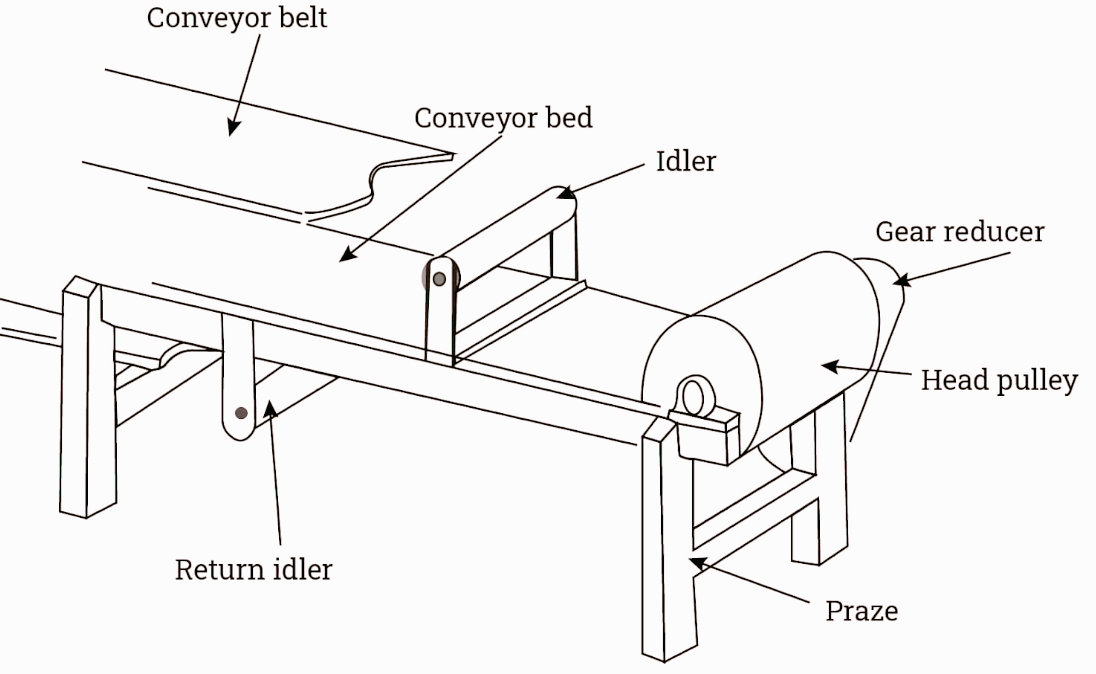

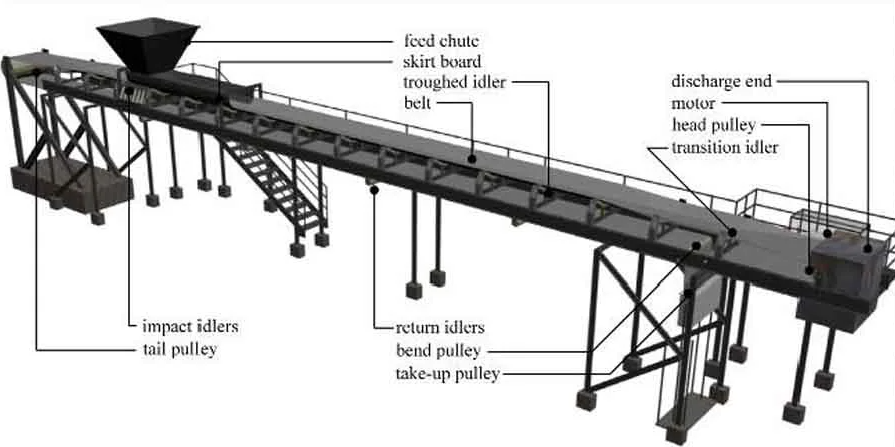

Working principle of oil resistant belt conveyor

The oil resistant belt conveyor relies on the motor to drive the reducer, the reducer drives the drive roller to rotate, and the drive roller drives the oil resistant conveyor belt to move through friction, thereby realizing the conveying of materials. During the conveying process, the material is placed on the conveyor belt and is transported from one position to another as the conveyor belt moves. Because the conveyor belt has oil resistance, it can maintain a good working condition even when conveying oily materials or working in an oily environment, ensuring the stability and reliability of the conveying process.

Details of oil resistant belt conveyor

Same as ordinary belt conveyor, it is mainly composed of drive device (motor, reducer), transmission roller, redirecting roller, roller (load roller, return roller), tensioning device, frame, conveyor belt and necessary protection devices (deviation switch, pull rope switch, etc.).

Technical specifications of oil resistant belt conveyor

|

Model |

Conveyor belt material |

Width range (mm) |

Length range (m) |

Speed range (m/min) |

Carrying capacity (kg/m) |

Special functions/remarks |

|

NYPD-01 |

PU |

300-1000 |

5-30 |

0.5-60 |

20-100 |

Resistant to low temperature, easy to clean |

|

NYPD-02 |

PVC |

400-1200 |

10-50 |

1-80 |

50-200 |

Stretch-resistant, suitable for medium loads |

|

NYPD-03 |

Synthetic rubber |

500-1500 |

15- 60 |

5-100 |

100-500 |

High wear resistance, excellent oil resistance |

|

NYPD-04 |

Stainless steel mesh belt |

300-1000 |

5-30 |

0.5-40 |

10-80 |

Suitable for oil resistance in high temperature environment |

|

NYPD-05 |

Teflon coating |

200-800 |

5-25 |

1-30 |

10-50 |

Anti-stick, good chemical stability |

What is the purpose of oil resistant belt conveyor?

The main purpose of oil resistant belt conveyor is to efficiently and stably convey various materials containing oil substances or working in oily environments. Its core value lies in that ordinary conveyor belts will quickly fail due to expansion, aging, and cracking after contact with grease, while oil resistant conveyor belts can effectively resist oil erosion with special rubber (such as nitrile rubber, polyurethane) or synthetic materials, ensuring production continuity and reducing maintenance costs.

①Automobile manufacturing industry: used to convey metal parts, stampings or waste with cutting fluids and lubricants to ensure smooth production lines.

② Food processing industry: In meat processing, baking, and fried food production lines, products rich in animal fat or vegetable oil, such as cooked food, cakes, potato chips, etc., are transported and must meet food hygiene standards.

③ Mechanical processing industry: Transport workpieces and metal debris stained with emulsion, cooling oil or engine oil.

④ Petroleum coking and mining industry: Used to transport coke, oil shale or oil-contaminated ore containing oil.

⑤ Grain and feed processing industry: Transport oil crops (such as soybeans, peanuts), oil cakes or feed containing oil.

In short, oil resistant belt conveyors are ideal choices for ensuring material transportation efficiency and equipment durability in places where the material itself contains oil, or the production process is contaminated with oil, or the working environment is seriously oily.

What are the safety standards for oil resistant belt conveyors?

The safety standards for oil resistant belt conveyors are mainly based on the "GB/T10595-2009 Conveyor Safety Specifications" and relevant mechanical equipment safety standards, focusing on structural safety, electrical safety, protective measures and emergency control. The equipment should be equipped with reliable anti-skid and anti-deviation devices to ensure stable belt operation when conveying oily materials; the electrical part should meet the requirements of oil-proof and moisture-proof design, and have overload and short-circuit protection functions; all transmission parts and rotating parts should be equipped with protective covers to prevent operators from accidentally touching them; emergency stop buttons and power-off protection devices should be set during operation to facilitate rapid response in emergency situations; at the same time, obvious safety warning signs should be set in the operation area.

For conveyors involving food processing, they must also comply with the "GB4806.1-2016 General Safety Requirements for Food Contact Materials". In summary, oil resistant belt conveyors must strictly comply with mechanical, electrical and operating safety specifications during design and use to ensure the safety of personnel and equipment operation.

Our wide range of product solutions

Oil resistant belt conveyors are used to convey metal stampings, castings, machined parts and assembled parts with oil stains. For example, during the processing of engine pistons, the surface of the workpiece will be contaminated with a large amount of cutting oil. The oil resistant conveyor belt can effectively avoid expansion and slipping, ensuring the stable transportation of the workpiece.

In the slaughtering, cutting, packaging and other links, meat and seafood will produce a lot of fat and grease. PU (polyurethane) oil resistant conveyor belts are widely used in meat cutting lines, cooked food cooling lines and packaging lines due to their non-toxic, grease-resistant and easy-to-clean characteristics, such as conveying sausages, bacon, fish fillets, etc.

In the mining or transportation process of some coal mines, coal may contain natural oil or be contaminated by lubricating oil. In coking plants, high-temperature coke may come into contact with oil during the cooling process. Oil-resistant conveyor belts can effectively cope with this harsh environment.

Manufacturer of oil resistant belt conveyors

Dahan Machinery is a manufacturer specializing in the production of conveying equipment. Its product line covers a variety of conveyors, including oil resistant belt conveyors. Each type of oil resistant belt conveyor has its specific application areas and advantages. When choosing, the specific working environment and needs should be considered. For example, in the chemical industry, conveyor belts with strong corrosion and oil resistance may be preferred, while in the food processing industry, hygiene and food safety standards will be given priority.

Customized service: Oil-resistant belt conveyors of different specifications, lengths, widths and speeds are provided according to the specific needs of customers.

High-quality materials: Conveyor belts are made of durable materials with good oil resistance to ensure long-term stable operation in working environments containing grease.

Diverse designs: Suitable for different industrial scenarios, such as food processing, chemical industry, electronic manufacturing and other industries, to meet various special requirements.

Perfect after-sales service: Provide installation guidance, repair and maintenance and other comprehensive service support to help users solve their worries.

If you are looking for oil resistant belt conveyors and consider choosing Dahan Machinery as a supplier, you can contact our customer service to obtain the latest product catalog and technical information to more accurately understand the specific models and their technical parameters they provide. In addition, you can also get more information about prices, delivery times and customization options through communication.