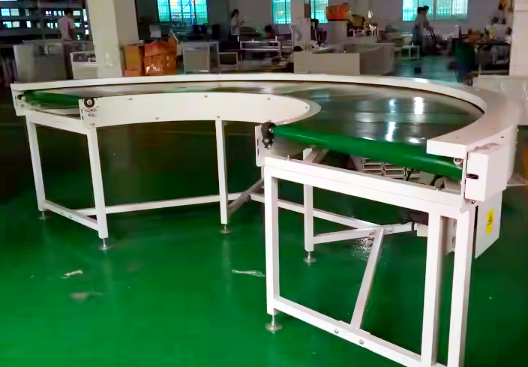

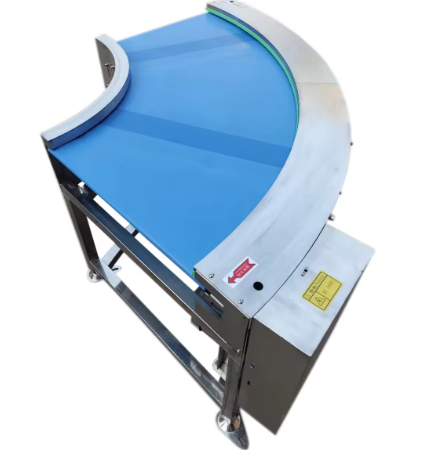

Curved belt conveyor

Equipment that changes the direction of conveying during the conveying process. Common angles include 30°, 45°, 90°, 180°, and even 360°, which can be customized according to needs

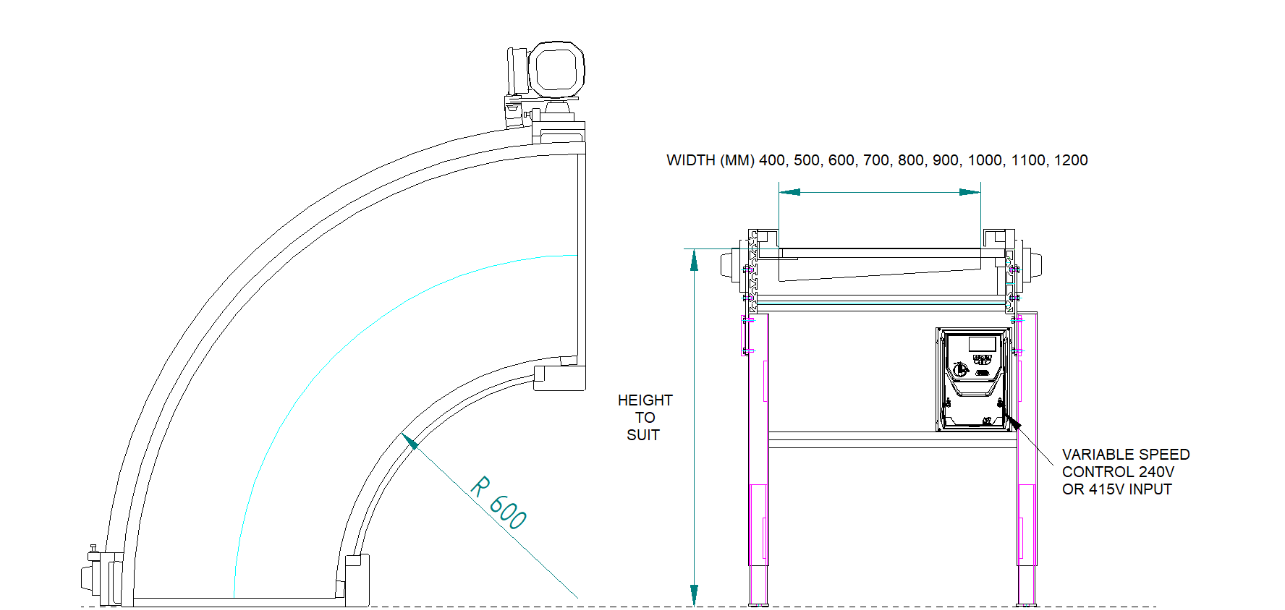

Curving angle: 60°/90°/180°

Curving radius: R<2m(6.5′)

Width: Maximum 1.5m(59″)

Speed: Maximum 120m(393′)/min

Motor power: 0.2-3.7kW (adaptable to AC220V/380V)

Conveying capacity: maximum 100kg/unit (adjusted according to material size)

Promise: free shipping/5-day delivery/30-day return and exchange/customization supported

Product Overview

Curved belt conveyor is a device that can realize material turning and conveying. It adopts special conical rubber-coated rollers, anti-deviation rollers and other structures, which can realize turning and conveying at different angles such as 30 degrees, 45 degrees, 90 degrees, and 180 degrees to meet diverse process requirements. During the conveying process, the belt runs smoothly, and there is no relative movement between the material and the belt, which can effectively avoid material damage.

Its core feature is that it can realize continuous and smooth curve conveying, breaking through the limitations of traditional linear conveying, ensuring that the belt runs smoothly on the curved path, and effectively preventing deviation and material accumulation. This not only significantly improves logistics efficiency and reduces the link of material transfer in the middle, but also minimizes the impact and damage of materials when turning, thereby improving the conveying effect and protecting the integrity of materials.

What can a curved conveyor be used for?

The curved belt conveyor is mainly used to achieve continuous and smooth material transportation in various industrial and commercial environments where limited space or the direction of material flow needs to be changed. It plays a key role in many application scenarios. For example, in logistics and express sorting centers, the curved belt conveyor can efficiently transfer parcels from one conveyor line to another seamlessly, optimize the sorting path, and increase the speed of parcel processing; in the airport baggage handling system, it ensures that passengers' luggage flows smoothly in complex and changeable paths and arrives at the destination quickly; in food processing and beverage production lines, turning conveyors can help products flexibly turn between different processes and adapt to compact production layouts.

In addition, in assembly lines in manufacturing industries such as automobiles and electronic products, it is also often used to transfer parts or semi-finished products from one workstation to another, avoiding the tediousness of manual handling and significantly improving production efficiency and automation. Through its unique turning ability, the curved belt conveyor greatly enhances the flexibility and space utilization of the conveying system.

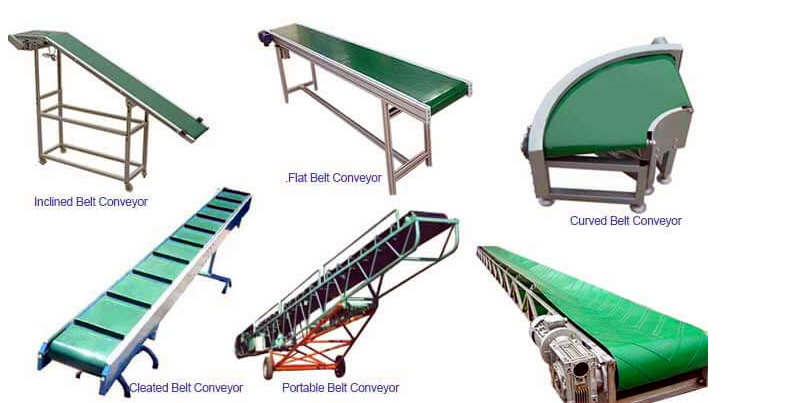

What are the types of curved belt conveyors?

①45° curved belt conveyor: moderate angle, taking into account steering flexibility and space utilization, and the belt has good operating stability.

In logistics warehousing, it is used to transfer the package from the main conveyor line to the sorting branch line. Auto parts workshop, convey small and medium-sized accessories (such as bearings and gears) to adjacent workstations.

②90° curved belt conveyor: right-angle turn, compact structure, and need to be matched with a conical roller or guide device to prevent the belt from running off.

The vertical process connection in the production line, such as the transfer of electronic products from the assembly line to the inspection line. In the supermarket sorting system, the goods are turned from the transverse conveyor belt to the longitudinal shipment port. In the pharmaceutical industry, it is used for the right angle transmission of pharmaceutical bottles and packaging boxes between filling and labeling stations.

③180° curved belt conveyor (ring/reflow type): realize U The material can be circulated and transported in a circular or circular manner, saving space.

Production line return transport, such as the circulation of unfinished parts in the automobile assembly line. Warehousing cache system, temporary storage of pending goods (such as the temporary storage link of e-commerce sorting center). Food industry washing line, empty bottles are 180° After turning, return to the filling station.

④Any customized curved belt conveyor at any angle: customized according to special site requirements (such as arc and spiral paths), professional design is required.

Slant conveying between floors in stereoscopic warehouses (such as any angle of 20°~70°). Baggage sorting in complex paths in airport baggage systems (non-standard angle turning). Chemical industry, special angle material transmission in corrosive environments (anti-corrosion materials are required).

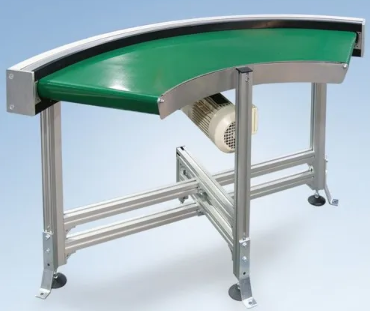

How does the curved belt conveyor work?

The belt turns by rotating the active roller and the driven roller, and the material deviates along the curve under the action of centrifugal force to complete efficient transportation. The turning angles cover 60°, 90°, and 180°, the conveyor belt width is 200mm-1500mm, and the speed can reach 45m/min.

① Driving principle: The traction force of the curved belt conveyor is The friction between the drive roller and the belt is transmitted. The motor drives the drive roller through the reducer, and the conveyor belt is dragged to rotate by the friction between the drive roller and the conveyor belt. The material falls on the rotating conveyor belt and is transported to the unloading end with the conveyor belt.

② Turning principle: There are two main types: forced turning and natural turning. Forced turning is to add a corner at the turning point without changing the main components of the original machine, which is suitable for large turns; natural turning is to make the conveyor belt bend naturally, with a simple structure and easy maintenance, which is suitable for small turns

Main structural components of curved belt conveyor

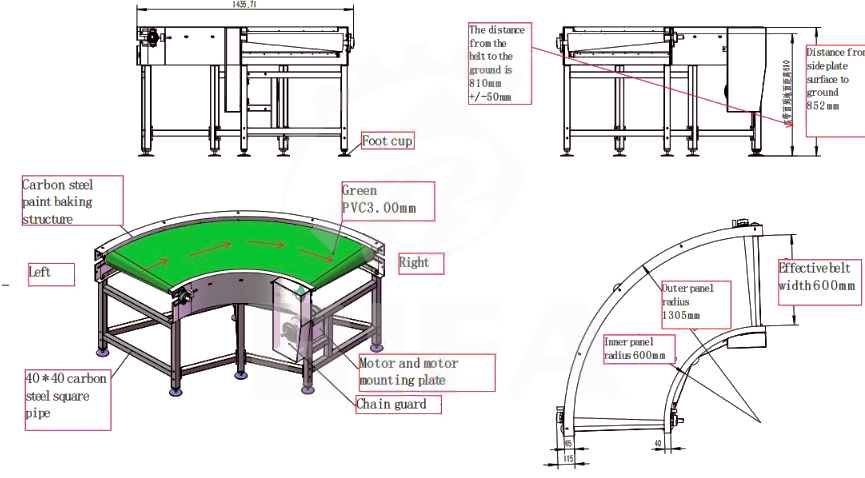

Belt: Commonly used conveyor belts are made of PVC, PU and other materials. In addition to conveying ordinary materials, they can also meet the conveying of materials with special requirements such as oil resistance, corrosion resistance, and anti-static. The food industry can use special food-grade conveyor belts.

Drum: Use a special cone bag The rubber roller helps guide the belt to turn and prevent it from running off the track.

Anti-runaway device: For example, a fan-shaped belt is equipped with a special anti-runaway roller, or a guide rib is welded on the outside of the conveyor belt at high frequency to make the conveyor belt run in a special guide rail.

Tensioning device: used to adjust the tension of the belt to ensure that there is enough friction between the belt and the roller to achieve stable material transportation. Common ones include spiral tensioning devices and heavy hammer tensioning devices.

Technical parameters of the curved belt conveyor

|

Model |

Turning angle |

Bandwidth (mm) |

Conveying speed (m/s) |

Maximum load (kg) |

Applicable scenarios |

Driving power (kW) |

Material/characteristics |

|

ZWP-30 |

30° |

300-800 |

0.1-1.5 |

≤100 |

Turning conveying of light and small items (such as electronic components, food packaging) |

0.75-2 .2 |

PVC belt, tapered roller to prevent deviation |

|

ZWP-45 |

45° |

500-1000 |

0.2-2.0 |

≤150 |

Small and medium-sized cargo turning (such as cartons, parts) |

1.5-3.0 |

PU belt, with guide ribs to prevent deviation |

|

ZWP-90 |

90° |

600-1200 |

0.3-2.5 |

≤200 |

Regular cargo right-angle turning (logistics sorting, auto parts) |

2.2-4.0 |

Rubber belt, heavy-duty roller |

|

ZWP-180 |

180° |

800-1500 |

0.1-1.2 |

≤80 |

Ring reflux conveying (such as production line circulation, storage cache) |

1.1-2.2 |

Food grade belt, low noise design |

|

ZWP-HD (heavy load) |

30°-90° |

1000-2000 |

0. 2-1.8 |

≤500 |

Heavy cargo turning (such as mechanical parts, building materials and panels) |

4.0-7.5 |

Steel cord belt, wear-resistant and corrosion-resistant |

What is the role of the redirecting roller in the belt conveyor?

In the belt conveyor system, the conveyor belt needs to form a closed loop. The redirecting roller is set at each turning point of the conveyor belt to guide the conveyor belt to change direction smoothly, thus forming a complete conveying path, including the return section. In some conveyor designs, the redirecting roller may also be used in conjunction with the tensioning device to provide and maintain the necessary tension for the conveyor belt. Appropriate tension can ensure that there is sufficient friction between the conveyor belt and the drive roller to prevent slipping, and ensure the smooth operation and shape retention of the conveyor belt.

What are the advantages of the curved belt conveyor

Improve conveying efficiency and continuity: During the turning process, materials do not need to stop, unload, or reload, achieving continuous and smooth transportation. This avoids material jams, accumulation, or waiting that may occur at traditional transfer points, greatly improving overall transportation efficiency.

Reduce material damage: The curved belt conveyor provides a gentle curve transition. This can effectively reduce impact, wear, and breakage for fragile, fragile, or appearance-required materials (such as glass products, food, and packaging), thereby protecting the integrity of the materials.

Wide applicability: It can convey various types of materials, including boxes, parcels, bagged materials, pallets, and some bulk materials, and can be customized according to different turning angles (such as 30°, 45°, 90°, 180°) and transportation requirements.

Related cases of curved belt conveyors

A large express delivery company uses it in its sorting center The turning conveyor system connects the main line and the sorting branch line: the curved belt conveyor is used to accurately turn the package from the main conveyor line to the corresponding sorting intersection; it significantly reduces the frequency of manual sorting and improves the degree of automation.

A food processing plant needs to transfer the packaged small-package biscuits back to another line for boxing: the curved belt conveyor is used to realize "rotating" conveying, saving the layout space of the factory, and the guide rails are equipped on both sides of the conveyor belt to ensure that the lightweight materials pass through the turning section stably.

Curved belt conveyor manufacturer

Xinxiang Dahan Vibration Machinery Co., Ltd. is a company that produces belt conveyors. It focuses on the research and development, production and sales of conveyor conveyors. It has 12 years of industry experience and provides a variety of conveying equipment including curved belt conveyors.

Bending radius: supports 90 degrees, 180 degrees, 45 degrees and customized angles Degree (such as R185mm, R600mm, R900mm, R1200mm and other standard bending inner radius)

Style design: standard plastic belt or rubber belt, optional material (such as PVC, PU, canvas)

Customization capability: bandwidth (500mm, 650mm, 800mm, 1000mm, 1200mm, etc.) and special specifications can be customized according to customer needs to meet the needs of different industries.

Curved belt conveyor is an indispensable equipment in modern automated material handling systems. It solves the core demand for changing the direction of objects during transportation, greatly improving space utilization and system efficiency. If you have a specific application scenario, a pain point that needs to be solved, or want to know the model and price of a specific type of turning machine, you can contact our customer service for consultation.