Mobile belt conveyor

Mobile belt conveyor is mobile and convenient for handling and deployment between different work sites. It is suitable for short-distance transportation and loading and unloading of bulk warehouses or single-piece items weighing 100 kgBelt width: 500/650/800/1000mm, customizable 100-500mm

Conveying capacity: 70-278m³/h

Conveying length: 3-26 meters

Conveying speed: 0.8-2.0 meters/second

Body material: carbon steel, stainless steel, aluminum alloy; conveyor belt: PVC, PU, rubber

Use: used in construction, food, mining, chemical industry, metallurgy and other industries, for short or medium-distance material transportation

Promise: free shipping/5-day delivery/30-day return and exchange/customization support

What is a mobile belt conveyor

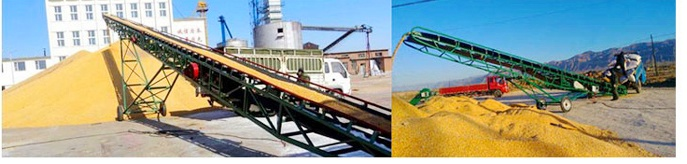

Mobile belt conveyor is a mechanical equipment that combines flexible movement and efficient transportation. It is highly maneuverable and can be quickly transferred to different work sites through mobile devices such as tires, tracks or tracks. It is suitable for loading and unloading scenarios with frequent site changes. In terms of conveying effect, it can continuously and stably transport a large amount of materials, whether it is loose coal, sand and gravel, or single packaged items, it can be easily carried.

The smooth operation of the conveyor belt can not only reduce material damage, but also realize horizontal or small-angle inclined conveying. The maximum inclination angle generally does not exceed 22°, which effectively prevents materials from slipping. At the same time, it has a fast conveying speed and high efficiency, and can complete a large amount of material transfer in a short time.

The difference between mobile belt conveyors and fixed belt conveyors

As an important material conveying equipment, belt conveyors are mainly divided into mobile belt conveyors and fixed belt conveyors according to whether they have the ability to move. There are significant differences between the two in structure, application scenarios and functions.

|

Features |

Mobile belt conveyor |

Fixed belt conveyor |

|

Image |

|

|

|

Structural features |

With mobile wheels, partly liftable |

Stable structure, suitable for long-distance, heavy-load transportation |

|

Conveying capacity |

Small and medium-sized material transportation |

Can meet the needs of large flow, long-distance continuous transportation |

|

Mobility |

Equipped with walking wheels and universal wheels, can move freely, adapt to multi-site operations |

Fixed installation in a specific position, suitable for long-term fixed-point operations |

|

Applicable materials |

Bulk materials or finished items with a single weight of ≤100kg |

Bulk bulk materials or heavy materials |

|

Common length |

Usually 3 to 20 meters |

Can reach tens of meters or even hundreds of meters |

|

Typical application scenarios |

Construction sites, temporary storage, loading operations |

Fixed operation processes such as mines, docks, and production lines |

Applicable materials for mobile belt conveyors

Mobile belt conveyors are widely used to transport various bulk materials and finished items due to their flexibility and versatility. For bulk materials, it can efficiently transport materials such as coal, sand, cement, grain (such as wheat, corn, rice), ore (such as iron ore, copper ore), chemical raw materials, fertilizer, feed, etc. These materials usually have a certain fluidity and require the continuity of the conveying process.

Mobile belt conveyors are also commonly used to transport various bagged items, cartons, parcels and other finished items, especially in occasions where frequent loading and unloading, stacking or short-distance transportation are required, such as logistics warehouses, port terminals, construction sites or agricultural product distribution centers. Its adjustable conveying height and mobility enable it to show excellent adaptability when handling materials of different types and forms.

What types of mobile belt conveyors are there?

Liftable type: equipped with hydraulic or mechanical lifting devices, it can flexibly adjust the conveying height (such as 0.5 meters to more than 10 meters) to meet the loading and unloading needs of different heights. For example, it can quickly dock with trucks, silos or multi-layer shelves, which is often used in scenes such as concrete pouring at construction sites and cargo loading and unloading at ports, and the height adjustment can improve the flexibility of operations.

Fixed height type: The fuselage has a fixed height, simple structure and low cost, and is suitable for scenes with a single conveying height. For example, short-distance transportation of parts in small workshops, flat handling of packaged goods in warehouses, etc., it is suitable for small and medium-sized enterprises with low requirements for equipment complexity and limited budgets.

Large inclination type: Using special patterned belts (such as corrugated sidewalls, transverse partitions) or adding baffles, breaking through the 22° inclination limit of ordinary belt conveyors, and achieving up to 90° vertical conveying. By increasing friction and blocking to prevent materials from sliding down, it is often used in scenes that require steep angles, such as lifting ore in mines, vertical storage of grain, and climbing transportation of chemical raw materials.

Telescopic type: The fuselage can be telescopically adjusted to adjust the conveying length (such as from 5 meters to 20 meters) through hydraulic or electric devices, and can flexibly adapt to different operating ranges. When shortened, it is suitable for narrow spaces (such as unloading inside containers), and when extended, it meets the needs of long-distance transportation (such as loading large trucks). It is widely used in logistics sorting centers, port container loading and unloading, and large-scale warehouse cross-regional transshipment.

What are the benefits of mobile belt conveyors?

Mobile belt conveyors can be flexibly moved to meet the needs of frequently changing loading and unloading locations such as ports, docks, construction sites, and farms, eliminating the complex process of fixed equipment installation. Secondly, the liftable type supports 0°-30° inclination adjustment, and some models have telescopic functions, which can quickly adapt to conveying tasks of different heights and distances. It has a strong conveying capacity (50-1500 tons/hour), suitable for bulk materials such as coal, sand, gravel, and grain, and finished items weighing ≤100kg, reducing material loss. A 2-hour no-load trial run can ensure stable operation.

Technical parameters of mobile belt conveyor

|

Model |

conveyor belt width (mm) |

conveyor length (m) |

conveyor speed (m/s) |

conveyor capacity (t/h) |

power (kW) |

|

DH300-6 |

300 |

6 |

0.8~1.6 (fixed/adjustable speed) |

10~30 |

1.5 |

|

DH400-8 |

400 |

8 |

1.0~2.0 |

20~50 |

2.2 |

|

DH500-10 |

500 |

10 |

1.0~2.0 |

30~70 |

3.0 |

|

DH600-12 |

600 |

12 |

1.0~2.5 |

50~100 |

4.0 |

|

DH650-15 |

650 |

15 |

1.0~2.5 |

80~120 |

5.5 |

|

DH800-20 |

800 |

20 |

1.2~2.5 |

100~160 |

7.5 |

What is the structure of a mobile belt conveyor?

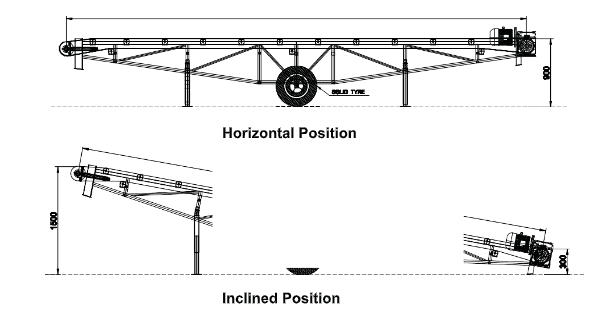

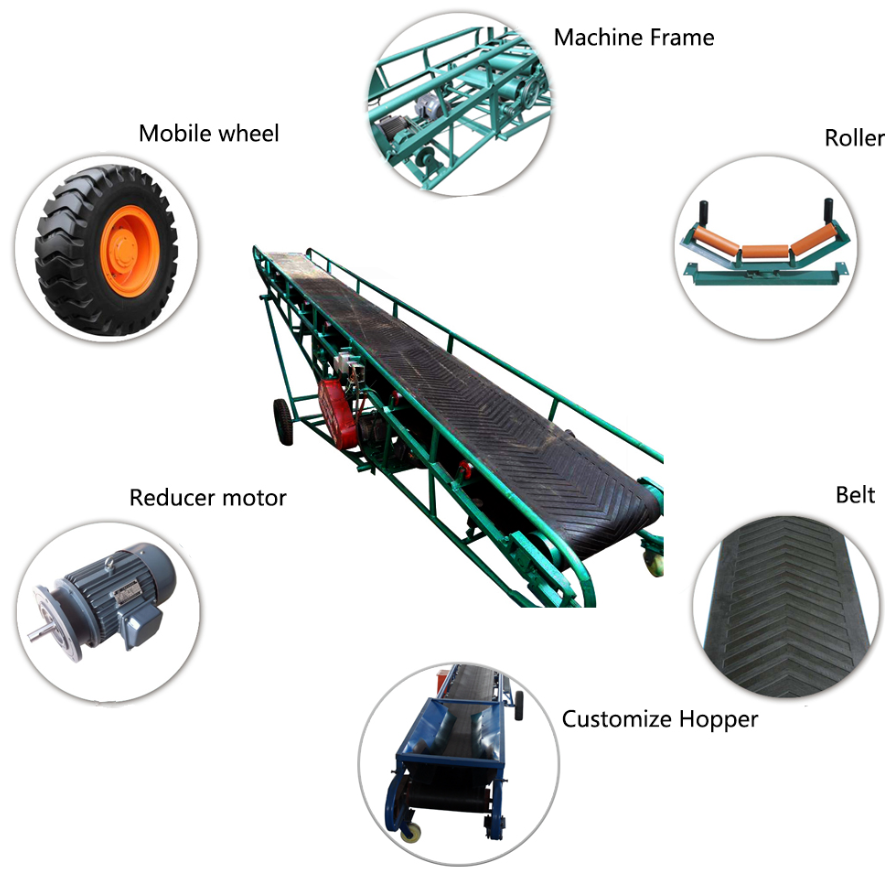

Mobile belt conveyor consists of a conveyor belt, a drive device, rollers, a frame, a roller, a moving wheel and a lifting mechanism.

As the main body for carrying and transferring materials, the conveyor belt is wound between the driving roller and the redirecting roller, and is driven by the motor to achieve continuous operation; the roller is set under the conveyor belt to support and guide the conveyor belt to run smoothly. The frame is usually made of steel, which bears the weight of the entire equipment and is connected to the lifting device and moving wheels.

The bottom is equipped with universal wheels or electric travel wheels, so that the whole machine can be flexibly moved to different working positions. The whole machine has a compact structure and flexible combination, which is suitable for working occasions where the on-site layout is not fixed and the space changes frequently.

What can mobile belt conveyors be used for?

The main application of mobile belt conveyors is in scenarios where frequent changes in work locations or temporary material transfers are required. For example, at ports and docks, it can efficiently unload bulk goods (such as coal, ore, and grain) from the cabin directly to the yard, or load them from the yard into trucks and trains; at construction sites, mobile conveyors can be used to transport construction materials such as sand, gravel, and cement from the stockpile point to the mixing station or construction surface, greatly improving the material turnover efficiency.

In the grain storage and processing industry, it is often used for grain storage, out of storage, unloading and loading and unloading of trucks to ensure the fast and safe circulation of grain; in addition, in open-pit mines, gravel yards and large storage and logistics centers, mobile belt conveyors can flexibly adjust the conveying lines according to production needs, realize the stacking, sorting or short-distance transfer of materials, and improve the overall operation efficiency.

Our wide range of product solutions

In open-pit mining, ore transportation faces problems such as complex terrain and large conveying volume. Our crawler-type large-inclination mobile belt conveyor adopts special patterned belts and high-strength frames, with a maximum conveying inclination of 35°, which can operate stably on muddy and rugged mine roads. After a large mine introduced this equipment, the daily ore transportation volume increased to 5,000 tons, which is 40% more efficient than traditional transportation methods, and the equipment failure rate decreased by 30%.

What is the price of a mobile belt conveyor?

The price of a mobile belt conveyor varies depending on the model, specification, material, configuration (such as bandwidth, length, lifting function, drive power) and supplier. The price range is roughly as follows:

Small mobile belt conveyor (such as 3-6 meters long, 500mm bandwidth, suitable for light materials): about $1,000-$3,000.

Medium-sized mobile belt conveyor (e.g. 6-15m long, 650-800mm belt width, suitable for bulk or packaged materials): about $3,000-$8,000.

Large or customized (e.g. 15-26m long, 1000mm belt width, with lifting/retracting function, suitable for heavy materials): about $8,000-$20,000 or higher.

To get an accurate price, you need to provide detailed information about your needs to the manufacturer or supplier, such as: What material do you need to convey? How many tons/cubic meters do you need to convey per hour? What is the required conveying length? What is the maximum lifting height? Are there any other special functions or environmental requirements? The more detailed information you provide, the more accurate the quotation you will get.