Cement conveyor belt

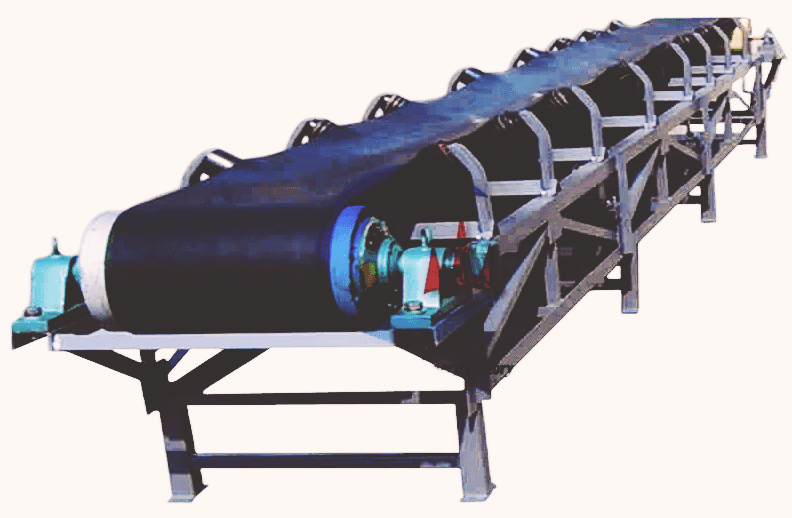

Cement conveyor belt is the core equipment used to transport raw materials (limestone, clay), clinker, finished cement and by-products such as powdered and granular materials in cement production. It is characterized by high efficiency, durability and adaptability to harsh environments.

Conveyor belt width: 400-2400 mm

Conveying capacity: customized

Application: widely used to convey various block, granular and powdered materials

Product description

Cement conveyor belt is an indispensable supporting equipment in cement production line. Cement conveyor belt is a material conveying equipment with strong adaptability. It is suitable for conveying powdered, granular, small block and bagged materials with a bulk density of less than 1.67t/m³, such as loose materials such as sand, gravel, ore, coal and cement. In addition, cement conveyor belt is not only suitable for small-volume conveying and short-distance conveying, but also for large-volume conveying and long-distance conveying, which is economical and practical.

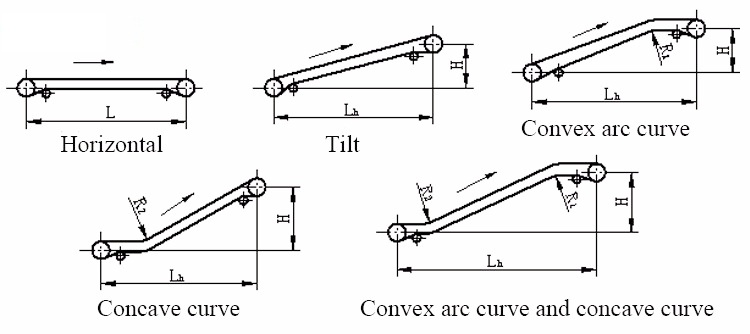

Classification of cement conveyor belts

Cement conveyor belts have various structural forms, including trough belt cement conveyor belts, sidewall belt cement conveyor belts, bucket elevators, pipe cement conveyor belts, skirt plate cement conveyor belts, and curved belt cement conveyor belts.

|

Cement conveyor belt types |

Picture |

Description |

Application |

Benefits |

|

Trough belt cement conveyor belts |

|

The belt is made into a trough shape to transport loose materials |

Long-distance transportation of bulk materials(Raw material handling) |

Efficient long-distance transportation, can handle a variety of materials |

|

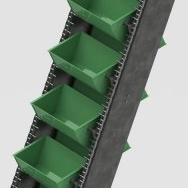

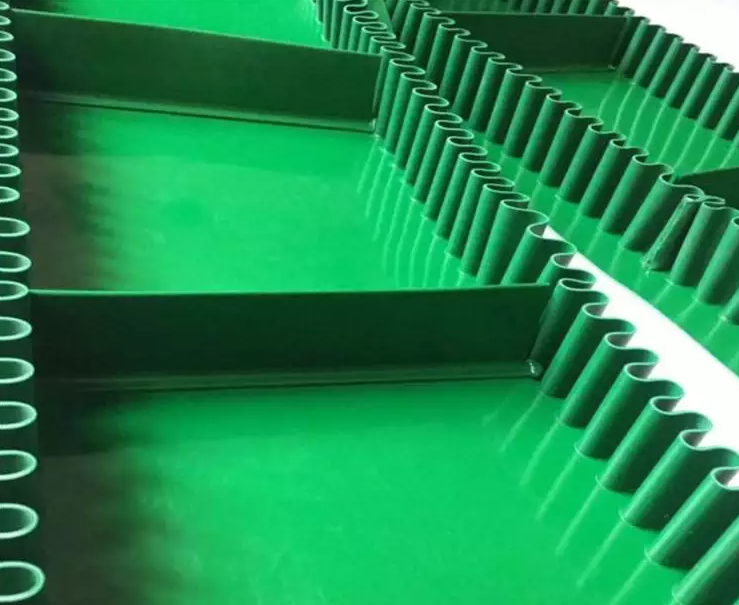

Sidewall belt cement conveyor belts |

|

Lifting cement belts are equipped with corrugated sidewalls on the edges, which can transport materials on steep slopes or even vertical lifts |

Steep angle vertical transportation, handling granular and powdered materials(Inclined transportation) |

Maximize space utilization by allowing steep slope transportation |

|

Bucket elevators |

|

Lifting cement buckets scoop up materials from a lower position and lift vertically to a higher position for unloading |

Vertical transportation of materials. Handling powder and granular materials(Lifting cement) |

Efficient vertical material transportation |

|

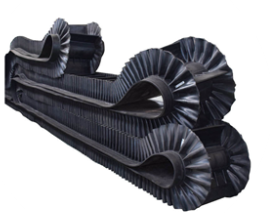

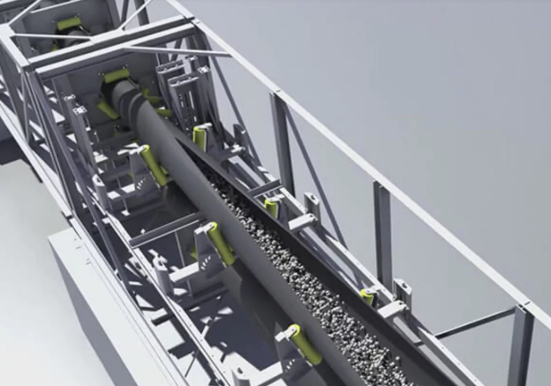

Pipe cement conveyor belt |

|

The belt forms a tube shape, enclosing the conveyed material to prevent material spillage and contamination |

Long-distance, curved transportation routes, enclosed transportation of fine and dusty materials(Dust-free transportation) |

Can navigate complex routes with horizontal and vertical curves |

|

Skirt cement conveyor belt |

|

Composed of overlapping metal plates or metal discs |

Handling hot, sharp and abrasive materials, short to medium distance material transportation(Clinker transportation) |

Can carry large heavy loads

|

Video of cement conveyor belt

How does the cement conveyor belt work?

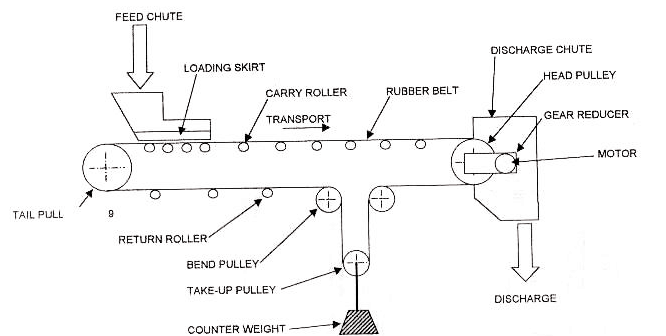

The working principle of the cement conveyor belt is based on the continuous movement of the conveyor belt to transport materials such as cement from one place to another. Its core mechanism is as follows:

Start the motor to drive the drum to rotate, driving the cement conveyor belt to circulate.

The cement material is put on the belt from the feed end and moves with the belt to the discharge end.

After unloading, the cement conveyor belt returns through the return roller, and the cycle repeats.

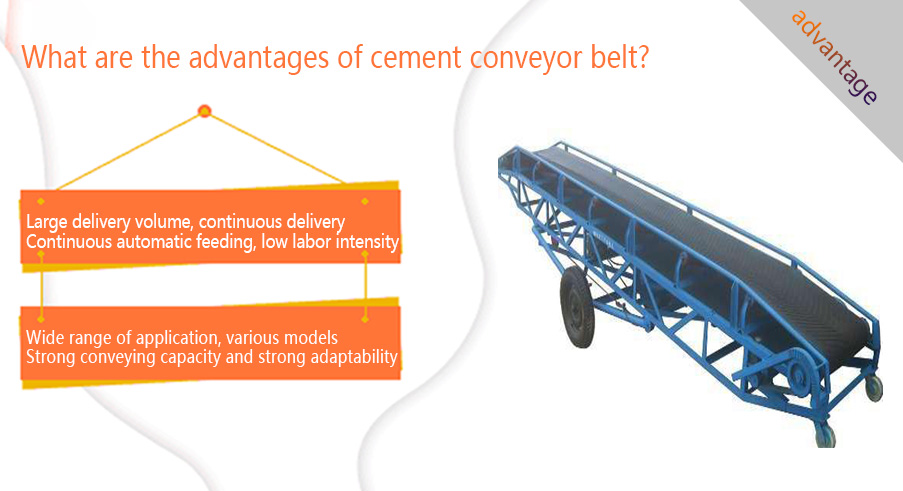

What are the advantages of cement conveyor belt?

Large delivery volume, continuous delivery

The cement conveyor belt has the advantages of long conveying distance, large conveying volume, continuous conveying, and reliable operation. It is an ideal continuous conveying equipment. The cement conveyor belt is reliable in operation, easy to realize automation and centralized control, and is particularly suitable for high-yield and high-efficiency mines.

Continuous automatic feeding, low labor intensity

The cement conveyor belt can efficiently convey various materials. In industrial production, the cement conveyor belt can be used as a link between cement equipment to form a continuous cement production line, realize the continuity and automation of production links, and reduce labor intensity.

Wide range of application, various models

The cement conveyor belt uses the principle of friction transmission to move, and has the advantages of no relative movement between materials and conveyor belts, low noise, low energy consumption, and standardized components. It is widely used in transportation and production lines in mining, metallurgy, chemical industry, casting, building materials and other industries, as well as production departments such as hydropower station construction sites and port terminals.

Strong conveying capacity and strong adaptability

When the conveying volume and conveying distance are large, the cement conveyor belt can be equipped with an intermediate drive device to meet the requirements. According to the conveying process requirements, a single cement conveyor belt or a group of cement conveying systems can be selected to meet the needs of different operation lines.

Structure of cement conveyor belt

The cement conveyor belt is mainly composed of a frame, a conveyor belt, a conveyor belt roller, a tensioning device, a conveying transmission device, etc.

Technical parameters of cement conveyor belt

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

|

DH400 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

30-60 |

|

3 |

3-4 |

4-7.5 |

|||

|

DH500 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

40-80 |

|

3 |

4-5.5 |

5.5-7.5 |

|||

|

DH650 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

80-120 |

|

4 |

7.5 |

7.5-11 |

|||

|

DH800 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

120-200 |

|

4 |

7.5 |

7.5-15 |

|||

|

DH1000 |

≤10 |

10-20 |

20-40 |

1.25-2.0 |

200-320 |

|

5.5 |

7.5-11 |

11-22 |

|||

|

DH1200 |

10 |

10-20 |

20-40 |

1.25-2.0 |

290-480 |

|

7.5 |

7.5-15 |

15-30 |

|||

|

DH1400 |

≤10 |

10-20 |

<20-40 |

1.25-2.0 |

400-680 |

|

11 |

15-22 |

22-45 |

|||

|

DH1600 |

≤10 |

10-20 |

<20-50 |

1.25-2.0 |

600-1080 |

|

15 |

22-30 |

30-75 |

|||

|

DH1800 |

≤10 |

10-20 |

<20-50 |

1.0-2.0 |

200-1500 |

|

18.5 |

30-45 |

45-110 |

|||

|

DH2000 |

≤10 |

10-20 |

<20-40 |

1.0-2.0 |

1000-2000 |

|

22 |

45-55 |

55-132 |

|||

|

DH2400 |

≤10 |

10-20 |

<20-40 |

1.0-2.0 |

1500-3000 |

Application of cement conveyor belt

Cement conveyor belt is a continuous conveying equipment widely used in the building materials industry (especially cement plants). It is widely used in the raw material storage, raw material preparation, clinker transportation and cement packaging of cement plants. It is an indispensable continuous conveying equipment in cement production lines.

Cement conveyor belt for sale

The price of cement conveyor belt depends on a variety of factors, including its length, width, capacity, and additional features such as automation and material quality. The average cost range is:

Basic model of small cement conveyor belt: $2,000 to $5,000, suitable for smaller operations or specific tasks such as loading and unloading bricks.

Medium cement conveyor belt: $5,000 to $15,000, providing higher capacity and usually equipped with more advanced features such as adjustable speed and improved material handling capabilities.

Large industrial cement conveyor belts: $15,000 to $50,000 or more, designed for large-scale brick production facilities. These conveyors are usually rugged and equipped with advanced control systems to optimize performance.

Prices may vary depending on customization, installation requirements and supplier pricing policies. You can consult us through email or customer service.

Cement conveyor belt manufacturer

Xinxiang Dahan Vibration Machinery Co., Ltd. is a manufacturer specializing in the production of conveying equipment, including belt conveyors for the cement industry. Cement conveyor belts can transport bulk materials (up to hundreds to thousands of tons per hour), are made of wear-resistant materials, and can be customized according to customer needs. Bandwidth (400-2400mm), length, inclination and conveying speed.

My whatsapp: +86 15236742901

e-mail: sale@xxdahan.com

Customized consultation: Dahan Machinery supports customized equipment based on conveying distance, material characteristics and production needs. It is recommended to contact its sales team directly for quotes.