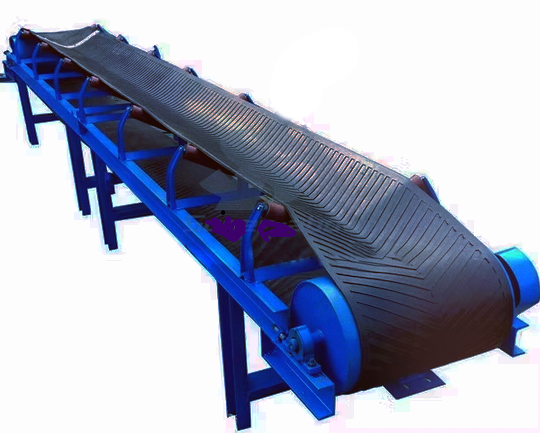

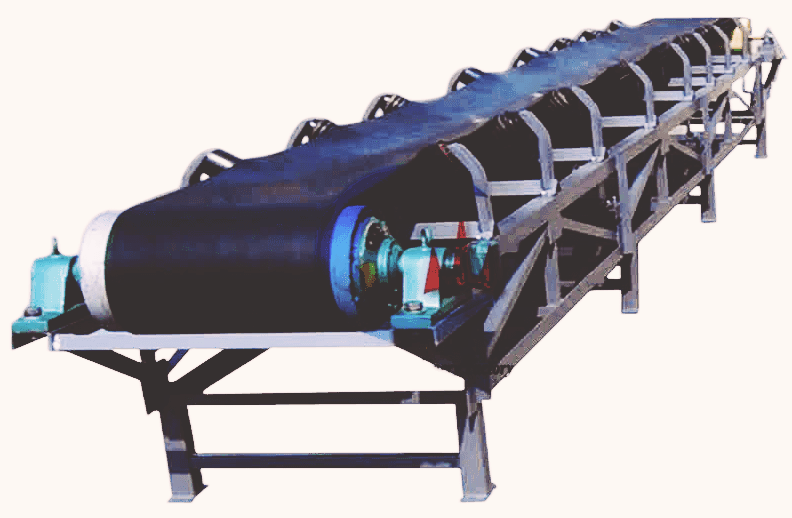

Mining conveyor belt

Mining conveyor belts are key equipment for loading and unloading in mines, coal mines and other environments. They are mainly used for conveyor ore, coal, sand and gravel and other block, granular or bulk unloading.

Product description:

Mining conveyor belts are important equipment for transporting bulk materials such as ore, coal, sand and gravel in the mining industry. They are used to efficiently and continuously transport bulk materials such as ore, coal, sand and gravel. Its design must meet the requirements of high strength, wear resistance, impact resistance and other harsh working conditions. Mining conveyor belts are heavy-duty systems used in the mining industry to transport large amounts of materials such as ore, coal, minerals and waste rock over short or long distances. It plays a key role in improving efficiency, reducing labor costs and ensuring the continuous flow of materials from the mining point to the processing plant, storage area or loading facility.

Types of mining conveyor belts

In the mining field, mining conveyor belts play a key role in efficiently transporting materials in all aspects of mining operations. In these systems, the types of mining conveyor belts used vary greatly, and each type is designed to meet specific operational needs and environmental challenges.

|

Type |

Description |

Application/Benefits |

|

Multi-layer Mining Belt |

Constructed from multiple layers of fabric bonded together |

Durability and flexibility to handle sharp and abrasive materials |

|

Straight Warp Mining Belt |

Woven design with strong impact and tear resistance |

Suitable for environments where sharp objects and high impact loads are common |

|

Wire Cord Mining Belt |

Wire rope reinforcement, known for high strength and low elongation |

Durability and ability to handle heavy loads, suitable for long-distance, high-load and high-speed applications such as open-pit mines |

|

Solid Braid Mining Belt |

Made from a single layer of solid woven fabric, fire-resistant |

Suitable for coal mining and other applications requiring fire resistance and resistance to sharp objects |

|

Heat Resistant Mining Belt |

Can withstand high temperatures and transport hot materials |

Suitable for cement plants and steel plants with temperatures up to 400°C |

|

Oil-resistant mining conveyor belts |

Belts have a special coating that resists the corrosive effects of oily and greasy substances |

Suitable for applications where the material is oily, greasy or wet |

|

Non-flammable, anti-static conveyor belts |

Safety-guided design reduces the risk of fire and static buildup |

Suitable for coal mining and other fire and anti-static environments |

|

Sidewall mining conveyor belts |

Equipped with sidewalls to hold the material in place |

Suitable for transporting materials vertically or at steep angles, maximizing space and efficiency in narrow mining operations |

Applications of mining conveyor belts Materials

Mining conveyor belts are used to handle a variety of materials and environments, including:

Abrasive and heavy materials: such as ores, minerals, rocks and coal, require strong belts that are durable, wear-resistant and have high tensile strength

Hot, oily and greasy materials: Mining conveyor belts are designed to withstand high temperatures. Oil-resistant conveyor belts are used to transport materials such as sinter or clinker

Fine powdery materials: Use belts with special surface textures or contours to prevent slipping

Steep slope materials: Sidewall and cleat belts are designed to transport materials vertically or on steep slopes, thereby maximizing space utilization and improving efficiency.

Wet and muddy materials: Waterproof and mud-resistant belts are used in environments where materials come into contact with water, ensuring the integrity of the belt and the safe transportation of materials.

Video of Mining Conveyor Belts

Construction of Mining Conveyor Belts

Mining conveyor belts used in mining operations are made from a variety of materials, each of which has specific properties that enhance the performance and durability of the conveyor belt. The main materials of mining conveyor belts include: rubber, wire rope, fabric, polyurethane (PU) and polyvinyl chloride (PVC), and the main components of the conveyor belt layer structure include carcass, top cover, bottom cover, flange and baffle.

Characteristics of mining conveyor belts

Mining conveyor belts are usually made of multiple layers of reinforcement materials, such as polyester, nylon or wire rope, to ensure reliability and durability in harsh working environments and heavy-duty transportation requirements.

Large conveying capacity: Mining conveyor belts are designed to handle large amounts of materials, requiring wide widths and high speeds to meet high production capacity and throughput.

Long-distance transportation: Mining conveyor belts are usually used for long-distance material transportation and can cross complex terrains such as mountains and rivers. The conveyor belts are long in length and high in strength to meet such long-distance transportation needs.

Corrosion and weather resistance: Mining conveyor belts are designed to be corrosion-resistant and weather-resistant. Commonly used materials include acid and alkali-resistant rubber, wear-resistant polyurethane and high-temperature resistant polytetrafluoroethylene.

High safety requirements: Mining conveyor belts need to be equipped with relevant safety devices, such as protective covers, emergency stop devices and anti-slip measures to ensure the safety of workers and equipment.

Technical parameters of mining conveyor belts, made into a table

|

Parameters |

Typical range |

Influencing factors |

|

Belt width (mm) |

500~2400 |

Conveying capacity, material particle size (such as 1000~1400mm for coal) |

|

Belt speed (m/s) |

1.0~5.0 |

High speed is easy to generate dust, low speed is suitable for large pieces of ore |

|

Tensile strength (N/mm) |

500~8000 (wire rope core) |

Determine the conveying distance (single machine can reach more than 10km) |

|

Working temperature (℃) |

-30~+120 |

Cold-resistant rubber is required in cold areas, and heat-resistant coating is required in high temperature environments |

How to choose a mining conveyor belt

When choosing a suitable mining conveyor belt solution, you need to consider multiple factors to ensure optimal performance. The following aspects require special attention:

Material characteristics: Different ores and coals have different physical characteristics, such as particle size, moisture and viscosity. These characteristics affect the selection and design of mining conveyor belts.

Conveying capacity: Mining conveyor belts must be able to handle large amounts of material. Consider the width, speed and working capacity of the mining conveyor belt to ensure that it meets the required conveying volume and capacity requirements.

Environmental conditions: Mining environments present challenges such as high temperature, low temperature, humidity and dust. The selected mining conveyor belt should be able to withstand these conditions and have the characteristics of wear resistance, corrosion resistance and high temperature resistance.

Safety requirements: Conveyor belts need to consider features such as protective covers, emergency stop devices and anti-slip measures to ensure the safety of workers and equipment.

Maintenance and durability: Mining conveyor belts require regular maintenance to ensure their normal operation and service life. When selecting a conveyor belt, consider its ease of maintenance and cleaning. Features such as easy disassembly, assembly and cleaning can help improve efficiency and durability.

Application of mining conveyor belts

Mining conveyor belts are widely used in the mining industry and are one of the important equipment for realizing continuous, automated and efficient transportation of materials. Mining conveyor belts have different application scenarios in different links. For example, in the coal mining industry, metal mines, non-metallic mines, etc., they are used to continuously transport raw coal between the underground coal mining face and the transfer point. They can also be used in raw ore transportation, clinker transportation and other links.

Customer Cases

|

|

|

|

|

|

Open-pit coal mines (high impact) |

Underground coal mines (explosion-proof) |

Metal mines (sharp materials) |

Long-distance transportation (>3km) |

Supplier of mining conveyor belts: Dahan Machinery

Choosing Dahan Machinery mining conveyor belts is mainly due to:

The service life of mining conveyor belts in abrasive conditions is extended by up to 40%

Reduced maintenance requirements can save thousands of dollars in labor costs each year

Mining conveyor belts improve energy efficiency and reduce operating expenses by up to 15%

Enhanced safety features protect workers and equipment

Customized solutions for specific material handling challenges

Whatever your mining application requirements are, Dahan Machinery can provide specialized mining belt types to meet your exact operational needs.