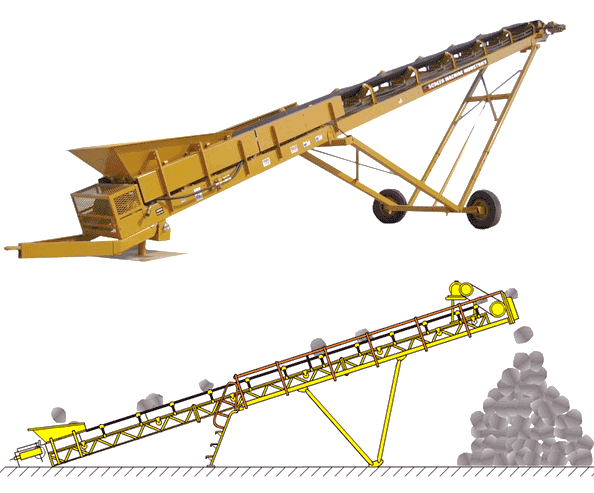

Construction belt conveyor

The material is transported from the feeding point to the unloading point through a continuously running conveyor belt. It is mainly used to transport bulk or piece materials such as crushed stone, sand, soil, and construction waste.

Material requirements: Suitable for materials with a bulk density of less than 1.67 tons/cubic meter and a temperature below 60°C

Conveying capacity: up to 1500 tons/hour

What is a construction belt conveyor?

Construction belt conveyor is a high-efficiency material handling equipment designed for construction sites, mines, and gravel yards, suitable for material transmission on continuous, straight or curved paths. It is known for its excellent conveying capacity and flexibility, and can easily handle a variety of construction materials including sand, gravel, soil and concrete blocks.

Construction materials suitable for belt conveyors

Bulk loose materials: natural sand, crushed stone, gravel and other sand and stone aggregates, used for concrete batching and foundation construction; fly ash and slag as auxiliary raw materials or fillers for construction materials; brick and tile fragments, concrete waste and other construction waste, which are easy to clean and centrally handle.

Powdered materials: cement powder is transported during concrete mixing or mortar preparation, stone powder and fly ash are used for mixed materials or repair projects.

Piece-formed materials: cement bags are transported to the yard or high-rise floors for feeding; bricks and blocks are conveniently and quickly transported to the construction site; mortar bags and concrete premix bags.

Working principle of construction belt conveyor

The working principle of construction belt conveyor is based on the continuous movement of the motor-driven conveyor belt to achieve material transportation. The specific process is as follows:

The motor drives the drive roller to rotate through the reducer, and the friction between the drive roller and the conveyor belt causes the conveyor belt to start circulating movement. The material is loaded onto the conveyor belt through the feed hopper or manual/mechanical means, and moves with the conveyor belt. The conveyor belt transports the material from the feed point to the discharge point along a fixed path (horizontal, inclined or turning) supported by rollers.

The material is unloaded at the end of the conveyor belt by gravity, unloading device or manual means to complete the transportation. The conveyor belt continues to circulate and repeats the above process to achieve continuous transportation.

What are the characteristics of building belt conveyors?

High operating efficiency: It can realize the rapid transportation of large quantities of materials, with a conveying capacity of up to 1,500 tons/hour, and can run continuously for 24 hours, greatly improving the material transportation efficiency. For example, in a concrete mixing station, raw materials can be transported to the mixer in real time to shorten the batching time.

Modular installation: The intermediate frame, rollers and other components can be quickly disassembled and assembled, which is convenient for adjusting the conveying route according to the construction progress. For example, in the construction of high-rise buildings, the conveyor length can be gradually extended as the floor rises.

Low energy consumption advantage: The rolling friction resistance between the conveyor belt and the roller is small, the motor power demand is low, and long-term use can save 30%~50% of energy costs. The core components (such as drive rollers and rollers) are made of wear-resistant materials and have a relatively simple structure, which reduces the probability of mechanical failure and ensures the construction progress.

Multi-scenario layout: It is suitable for material transfer within the construction site plane (such as from the material yard to the mixer). The material can be lifted to the floor or high silo by adjusting the inclination angle (generally ≤18°, special design can reach 30°). Through the design of convex or concave arc segments, obstacles (such as building bodies, construction machinery) can be bypassed to adapt to complex construction site layouts.

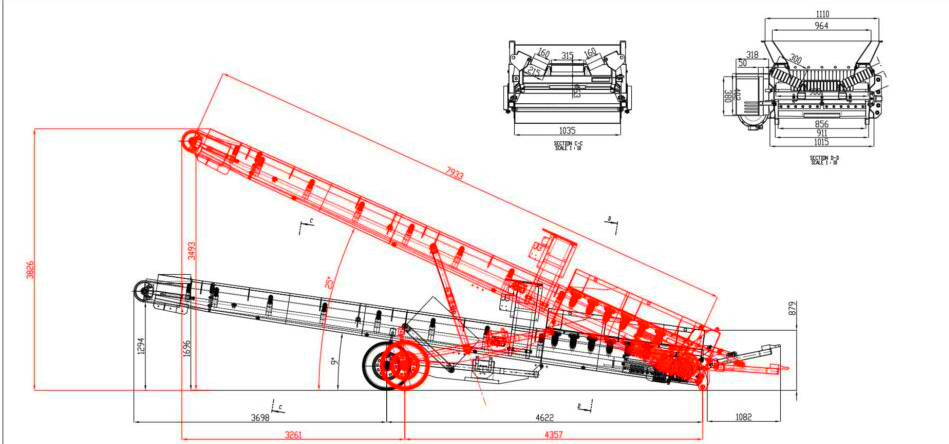

Technical parameters of construction belt conveyors

The following is a reference table of technical parameters of common construction belt conveyors, which can be used to transport sand, gravel, cement, concrete, bricks and other construction materials. The data is based on common specifications used on engineering sites

Model Bandwidth (mm) Conveying length (m) Conveying capacity (t/h) Conveying speed (m/s) Motor power (kW) Tilt angle (°) Remarks

B400 400 5–15 20–40 0.8–1.6 1.5–3.0 ≤20 Suitable for small construction sites

B500 500 5–20 30–60 0.8 –2.0 2.2–4.0 ≤20 Commonly used for sand, gravel, mud and other materials

B650 650 10–30 50–100 1.0–2.5 3.0–5.5 ≤20 Suitable for large-scale transportation operations

B800 800 15–40 80–150 1.0–3.15 4.0–7.5 ≤18 Commonly used for commercial concrete transportation

B1000 1000 20–50 100–200 1.25–3.15 5.5–11.0 ≤15 Concentrated loading of building materials

What can belt conveyors be used for in the construction field?

Belt conveyors are mainly used in the construction field to achieve efficient and continuous transportation of materials. A large amount of aggregates such as sand, gravel, and crushed stone are required at the construction site. Belt conveyors can transport these bulk materials from the yard or mixing station to the designated location at the construction site. At the concrete mixing station, the belt conveyor is responsible for transporting the mixed concrete to the pouring area. Especially in large-scale projects, continuous feeding can be achieved to ensure the continuity of construction.

Belt conveyors can transport cement bags, bricks and other finished materials to the top of the floor with a certain inclination angle to meet the material feeding needs of high-rise buildings and facilitate construction. Construction waste generated during the construction process can be transported to designated areas or garbage collection points by belt conveyors to assist in site cleaning and keep the construction environment clean. Fine particles or powdered materials such as mortar, stone powder, cement powder, etc. can also be transported by special wear-resistant belt conveyors, which are suitable for mixing or on-site batching.