Conveyor belt for bulk material handling

Conveyor belt for bulk material handling is a continuous conveying machine that uses rubber belt, plastic belt or steel belt as a load-bearing and traction component, suitable for conveying loose materials such as powder, granular, block, etc. Its core is to rely on the movement of the ring conveyor belt between the driving roller and the redirecting roller to realize the material conveying.

Product Introduction

Conveyor belt for bulk material handling is a mechanical equipment that carries and transports granular or powdery materials through a continuous moving surface (such as rubber belt, plastic belt, metal mesh belt, etc.). Its core function is to use the friction between the conveyor belt and the material to transport the material from the feeding point to the unloading point to achieve efficient and continuous material transfer. Based on the principle of mechanical transmission, it is a continuous conveying equipment designed for discrete materials such as particles, powders, and small blocks. Its core function is to transport materials from the feeding end to the unloading end through the movement of the ring conveyor belt. It is suitable for large-scale material handling in industries such as mining, metallurgy, chemical industry, grain, and building materials.

Video of conveyor belt for bulk material handling

Types of conveyor belt for bulk material handling

|

Specific types |

Picture |

Material/structural features |

Applicable material characteristics |

Typical application scenarios |

Advantages |

|

Flat conveyor belt |

|

Smooth surface, no additional structure |

Materials with good fluidity and uniform particles (such as grains, sand) |

Horizontal or small angle conveying (angle ≤15°) |

Simple structure, high conveying efficiency |

|

Pattern conveyor belt |

|

Surface with convex ridges, herringbone or wavy patterns |

Low fluidity, easy-to-slip materials (such as wet sand, clay) |

Medium angle conveying (angle 15°~25°) |

High friction and good anti-slip effect |

|

Skirt baffle conveyor belt |

|

Skirts + middle baffles on both sides (vertical or inclined) |

Large angle or vertical lifting scenario (angle ≥25°) |

Mine lifting, vertical grain transportation |

Prevent material from sliding, can achieve 90° Vertical conveying |

|

Corrugated sidewall conveyor belt |

|

flat bottom, corrugated sidewalls + partitions on both sides |

large particles or high drop materials (such as ore, construction waste) |

large angle conveying (angle 30°~90°) |

flexible conveying angle, can handle large pieces of materials |

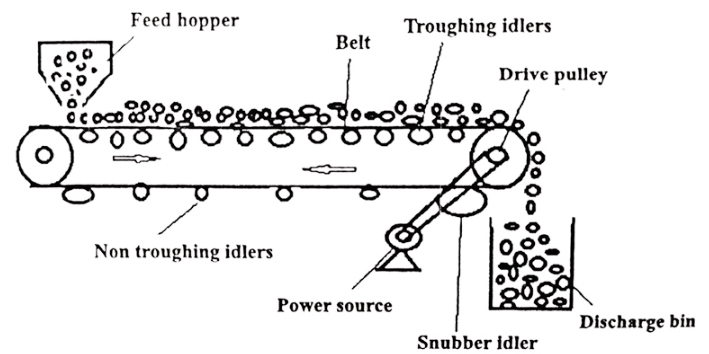

What is the working principle of conveyor belt for bulk material handling?

Conveyor belt for bulk material handling system uses mechanical power to generate continuous movement of the belt, using friction to transport loose materials to a specified path. The design and specific components used are tailored to the characteristics and application requirements of the bulk materials being transported.

Bulk materials are fed to the conveyor belt at the loading point through a feeder.

The motor drives the head pulley to rotate, and the friction between the pulley surface and the bottom of the belt pulls the belt forward.

The load-bearing rollers along the length of the conveyor support the weight of the belt and the material, and the belt is usually shaped into a groove to maximize the material.

The continuous movement of the belt transports the bulk material from the loading point to the unloading point.

Characteristics of conveyor belt for bulk material handling

Specially for non-unitized materials: The core design of bulk material conveyor belts is to convey large quantities of loose materials without independent packaging, such as granular, powdered, and block materials, such as coal, ore, grain, sand, cement, chemical raw materials, etc.

Large conveying capacity and efficiency: Conveyor belts for bulk material handling are usually designed to be able to convey large quantities of materials at a high speed and in a continuous manner to achieve efficient material handling.

Diverse structures and forms: In order to prevent bulk materials from spilling during transportation, many bulk material conveyor belts will use special structures such as skirts and sidewalls, especially when conveying at an angle.

Material adaptability: It can convey granular materials ranging from 0.1mm to 300mm, including powdered, granular, block and paste materials. For high humidity (such as wet coal, wet sand) or sticky materials (such as flour, powdered sugar), special anti-stick coatings or pattern designs are used.

Technical parameters of conveyor belt for bulk material handling

|

Technical parameters |

Description |

Typical range |

Technical parameters |

Description |

Typical range |

|

Belt width |

Conveyor belt width, determines the conveying capacity |

400-2500 mm |

Belt speed |

Belt running speed, affects conveying efficiency |

0.5-4 m/s |

|

Conveying capacity |

Amount of material conveyed per unit time |

100-5000 t/h |

Conveying length |

Effective conveying distance of a single-section conveyor belt |

10m-10km |

|

Inclination |

Angle between the conveyor belt and the horizontal plane |

0°-90° |

Belt material |

Conveyor belt main body material, affects durability and adaptability |

Rubber, PVC, PU, wire mesh, nylon |

|

Belt strength |

Tensile strength of the belt body, determines the load-bearing capacity |

100-5000 N/mm |

Control system |

Operation control mode, affecting the degree of automation |

Manual, PLC, frequency conversion control |

|

Roller diameter |

Diameter of the roller supporting the belt body, affects running stability |

50-200 mm |

Safety device |

Auxiliary system to protect equipment and personnel safety |

Anti-deviation switch, emergency stop device, overload protection |

|

Drive power |

Drive motor power, determines system power |

1-500 kW |

Operation life |

Depending on material abrasiveness and maintenance |

1-10 years |

|

Tension force |

Force value to maintain belt tension and prevent slipping |

1000-50000 N |

Working environment temperature |

Ambient temperature range suitable for conveyor belt |

-40°C to +120°C |

|

Material particle size |

Applicable material particle size |

0.1mm-300mm |

Material density |

Applicable material bulk density |

0.5-4 t/m³ |

|

Number of belt layers |

Number of fabric or steel wire layers of belt body, affecting strength and flexibility |

1-10 layers |

|

|

|

Recommended mesh count for conveyor belt for bulk material handling

The mesh count is an indicator to measure the particle size of the material, usually indicating the number of mesh holes per inch of length. The larger the mesh count, the smaller the particles.

|

Mesh size (mesh) |

corresponding particle size (mm) |

material form example |

|

Below 10 mesh |

>2 mm |

coarse block, crushed stone |

|

20~60 mesh |

0.25~0.85 mm |

sand, granular material |

|

80~200 mesh |

0.074~0.18 mm |

flour, fly ash |

|

Above 200 mesh |

<0.074 mm |

ultrafine powder, carbon black |

Key description

Fine powder material: For example, fine powder above 200 mesh is easy to raise dust and adhere, and it may be necessary to choose a conveyor belt with a side guard, closed structure or special surface treatment to reduce losses and environmental pollution.

Medium granular material: For example, particles between 20 mesh and 200 mesh are the most commonly handled material range of conveyor belts, and various types of conveyor belts have applicable models.

Coarse block material: For example, block materials less than 20 mesh need to consider the strength and impact resistance of the conveyor belt and measures to prevent materials from rolling off.

Application of conveyor belt for bulk material handling

Bulk materials (such as granules, powders, and block materials) are widely used in many industries due to their non-fixed shape, diverse particle sizes (from high-mesh fine powder to low-mesh large blocks), fluidity differences, and abrasiveness.

Mining industry: For ore transportation (such as iron ore and copper ore) from the quarry to the crushing station and the beneficiation plant, a corrugated sidewall conveyor belt is used to achieve a 45°-90° large-angle climb and reduce infrastructure costs.

Port industry: For loading/unloading of grains such as soybeans and wheat, tubular conveyor belts reduce dust pollution and meet environmental protection requirements. The belt speed can reach 4.5m/s, which improves loading and unloading efficiency.

Building materials industry: For the transportation of limestone and clay from the raw material field to the crusher and preheater, heat-resistant conveyor belts are used to transport cement clinker, which extends the service life by 30%. The skirt + pattern design prevents sand and gravel from sliding.

Chemical industry: precise conveying of powder and granular materials, pre-packaging conveying of urea and compound fertilizer, and conveying of raw salt and industrial salt. Conductive rubber conveyor belts prevent static electricity accumulation of powder materials.

Agricultural industry: large-scale processing of grain and feed, and transportation of corn and wheat from grain depots to processing plants. Use food-grade conveyor belts for bulk material handling to transport grain and reduce the risk of cross-contamination.

Why choose Dahan Machinery's conveyor belt for bulk material handling?

The reason for choosing Dahan Machinery's bulk material conveyor belt is mainly based on its significant advantages in technical strength, product performance, industry adaptability, service guarantee, etc., as follows:

Large-angle conveying technology: Dahan Machinery's large-angle belt conveyor can achieve 0°-90° large-angle conveying, and even vertical lifting

Weather resistance and durability: Conveyor belt materials include rubber, silicone, PVC, PU, etc., which can be customized according to material characteristics

Multi-industry coverage: Products are widely used in mining, ports, building materials and other fields, and can convey bulk materials such as coal, ore, and grain

Customized design: Provide personalized design solutions based on user conveying volume, conveying length, site conditions, etc.

Dahan Machinery's conveyor belt for bulk material handling has become the first choice for users in many industries with its leading technology, excellent performance, perfect service, and high cost-effectiveness. Whether it is large-angle conveying, weather-resistant design, or customized solutions, they can meet the needs of efficient conveying under complex working conditions.