lightweight conveyor belt

Lightweight conveyor belt is a conveying material composed of a multi-layer fabric skeleton (such as polyester EP cloth) and a coating material (such as PVC, PU, PE, silicone, Teflon, etc.). The thickness is generally less than 7mm and is suitable for medium and low load, short distance, and high frequency conveying scenarios.

Thickness: 0.8mm-5.0mm

Temperature range: -50℃~+260℃

Tensile strength: 6-25N/mm

Is it food grade: customizable (such as PU, PE, blue PVC)

Special functions: anti-static, flame retardant, oil resistant, perforation, guide strips, skirts, etc.

Product description

Lightweight conveyor belt is a solid material conveyor belt with a lighter material, mainly used for transporting and handling light materials. With lightweight materials as the core, the conveying medium is processed by special technology and is usually made of rubber, PVC, PU and other materials. It is widely used in light industrial fields such as food, medicine, electronics, logistics, and printing. Its core advantages are light weight, easy installation, low maintenance cost, and can be customized with different materials, colors and patterns according to needs.

Different types of lightweight conveyor belts

lightweight conveyor belts are mainly used in occasions where the conveying volume is not high, the material is light, and the environment is relatively clean. There are many types, which can be classified according to different materials, surface characteristics, structures, etc.

|

Classification basis |

Type |

picture |

Features |

Typical applications |

|

According to the material of the covering layer |

PVC lightweight conveyor belt |

|

Low cost, general resistance, and can be subjected to a variety of surface treatments |

Food processing (not directly contacted), electronics, logistics and other industries |

|

PU light conveyor belt |

|

Excellent resistance and good elasticity |

Food processing, medicine and other industries with high requirements for hygiene and wear resistance |

|

|

PE light conveyor belt |

|

Good chemical corrosion resistance, low temperature resistance, non-toxic and tasteless, low friction coefficient |

Partial food transportation, low temperature environment transportation, etc. |

|

|

TPU lightweight conveyor belt |

|

Excellent comprehensive performance, good low temperature performance |

Precision electronics, places with high requirements for wear resistance and flexibility |

|

|

Silicone light conveyor belt |

|

Excellent high and low temperature resistance, aging resistance, non-stickiness |

Special environments such as high and low temperature food processing, medicine, etc. |

|

|

According to surface characteristics |

flat lightweight conveyor belt |

|

smooth surface, moderate friction coefficient |

widely used in horizontal or small-angle inclined transportation in various industries |

|

patterned light conveyor belt |

|

with various patterns on the surface to increase the friction coefficient |

inclined transportation, lifting transportation and other occasions requiring greater friction |

|

|

guided lightweight conveyor belt |

|

with guide strips on the back to prevent the conveyor belt from running off |

conveying systems that require precise operation |

|

|

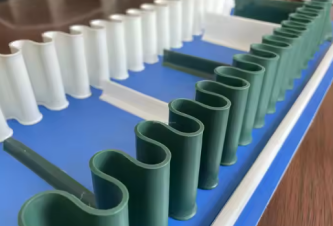

skirt, sidewall lightweight conveyor belt |

|

with skirts or transverse sidewalls, used for large-angle conveying of bulk or easy-to-roll materials |

large-angle conveying of bulk materials, food, etc. |

Video of lightweight conveyor belts

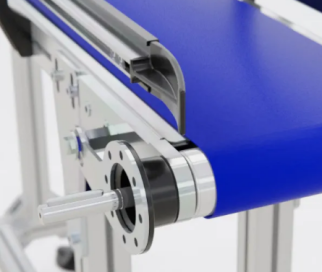

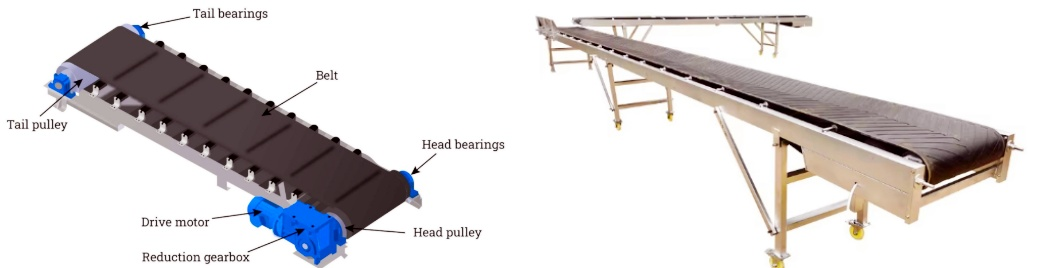

What is the structure of lightweight conveyor belts

Lightweight conveyor belts usually adopt a multi-layer composite structure, with the core being the skeleton layer and functional coatings covering the upper and lower parts. They are specifically divided into the following parts: skeleton layer (fabric layer), upper covering layer (working surface), lower covering layer (non-working surface), and adhesive layer additional components.

Skeleton layer: provides tensile strength and structural stability, and withstands tension and load during transportation.

Upper covering layer: directly contacts the material and needs to be wear-resistant, oil-resistant, chemical-resistant or meet food-grade requirements.

Covering layer: contacts the roller or supporting surface, provides friction and wear resistance, and supports smooth operation.

Adhesive layer: firmly bonds the skeleton layer to the covering layer to ensure the stability of the overall structure.

Additional components: skirts/baffles, guide bars, perforations, etc.

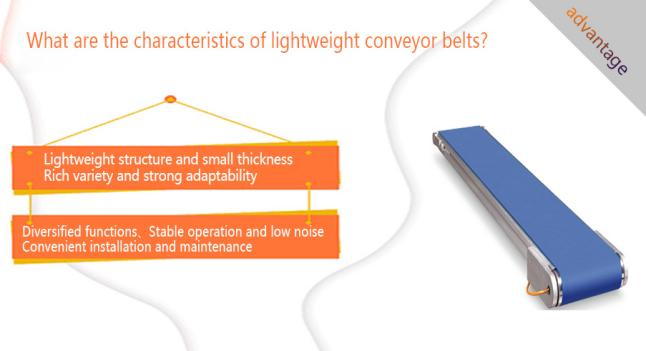

What are the characteristics of lightweight conveyor belts?

Lightweight structure and small thickness: The belt body is thin and light, which is convenient for equipment design and installation; the thickness is usually between 0.8mm and 5mm; suitable for short-distance and fast transportation.

Rich variety and strong adaptability: PVC, PU, PE, silicone, Teflon, etc.; support a variety of surface treatments; can be matched with a variety of structures such as baffles to meet different transportation requirements.

Diversified functions: food grade optional (such as PU, blue PVC, etc.); support oil-proof, waterproof, anti-static, high temperature resistant, corrosion-resistant and other functions customization;

Stable operation and low noise: strong flexibility, can adapt to smaller roller diameter (minimum 10mm); stable cooperation with drive roller and tension wheel, high transmission efficiency and low noise;

Convenient installation and maintenance: can provide a variety of joint methods such as hot melt joints, mechanical buckles, nail buckles, etc.; quick installation, low on-site maintenance and replacement costs.

Technical specifications of lightweight conveyor belts

|

Technical parameters |

PVC conveyor belt |

PU conveyor belt |

Silicone conveyor belt |

Rubber conveyor belt |

Modular plastic belt |

|

Material composition |

PVC+polyester fiber |

Polyurethane+polyester/nylon fabric |

Silicone rubber+glass fiber |

Natural/synthetic rubber+fabric |

PP/PE module splicing |

|

Thickness range (mm) |

0.5~5.0 |

0.3~6.0 |

0.5~8.0 |

1.0~10.0 |

Module height 5~15 |

|

Tensile strength (N/mm) |

10~50 |

15~80 |

10~40 |

20~100 |

Depends on module structure |

|

Working temperature (℃) |

-10~+80 |

-30~+90 |

-60~+250 |

-30~+120 |

-40~+90 |

|

Abrasion resistance |

Medium |

Excellent |

Good |

Excellent |

Good |

|

Chemical resistance |

Weak acid and alkali resistance, grease |

Oil resistance, most solvents |

Acid and alkali resistance, oxidants |

Oil resistance, weak acid and alkali resistance |

Acid and alkali resistance, alcohol |

|

Surface characteristics |

Glossy/patterned/anti-static |

Glossy/rough/conductive |

Anti-stick, high friction |

High friction, anti-slip |

Grid/flat design |

|

Elongation (%) |

5~15 |

3~10 |

5~20 |

10~25 |

Almost no elongation |

|

Maximum belt speed (m/s) |

2.0 |

3.0 |

1.5 |

2.5 |

1.8 |

Application of lightweight conveyor belts

Lightweight conveyor belts are a kind of lightweight and flexible material as the base material. They play an important role in industries that need to convey light weight, require a smooth conveying process, low noise, and have high hygiene requirements in some scenarios. Choosing the right type of lightweight conveyor belt requires comprehensive consideration based on the specific application scenario and the characteristics of the conveyed material. lightweight conveyor belts are widely used in food, medicine, electronics, logistics, packaging and other industries due to their flexibility, diversity and adaptability to different environments and materials.

Supplier of Lightweight Conveyor Belts

Our lightweight conveyor belts serve a variety of industries, including agriculture, packaging/handling, wood products, recycling, food processing, power, and tobacco. To meet the unique needs of these industries, we stock a wide selection of lightweight conveyor belts: PVC, rough top, polyurethane, cotton cloth, monofilament.

Each lightweight conveyor belt is designed for a specific application and use; in the world of conveyor systems, a one-size-fits-all approach does not work. We will help you select the right conveyor belt based on your specific needs to ensure optimal performance and maximize the life of your conveyor system.

Price of Lightweight Conveyor Belts

The price of lightweight conveyor belts is affected by many factors, including material, specifications, brand, customization requirements and order quantity, supplier location, etc. There are large differences.

Thickness/Number of layers: The more layers and the thicker the belt, the higher the price.

Function customization: Add baffle/guide/skirt: ¥5–¥30 per meter; Anti-static/flame retardant/perforated: Customization is required, and the unit price will increase by 10% to 30%;

Joint method: Hot-melt joints are generally included in the cost; nail joints or mechanical buckles are charged extra;

Order quantity: Large quantity is preferred, and the unit price of whole roll purchase is lower.

If you need a specific quotation for a specific type or Dahan machinery, please provide more details (such as required specifications, quantity, delivery location), and I can assist in further screening, help you choose the right conveyor belt and make a detailed quotation.